Glue roller with delimited gluing region

A rubber roller and gluing technology, which is applied in the field of labels, can solve the problems of dry glue lines and difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In the following, identical or identical type elements are identified with the same reference numerals. The description of these elements is not repeated for clarity. Furthermore, it should be understood that some or all elements in the following embodiments may be replaced by or combined with elements of the same type described in connection with other embodiments.

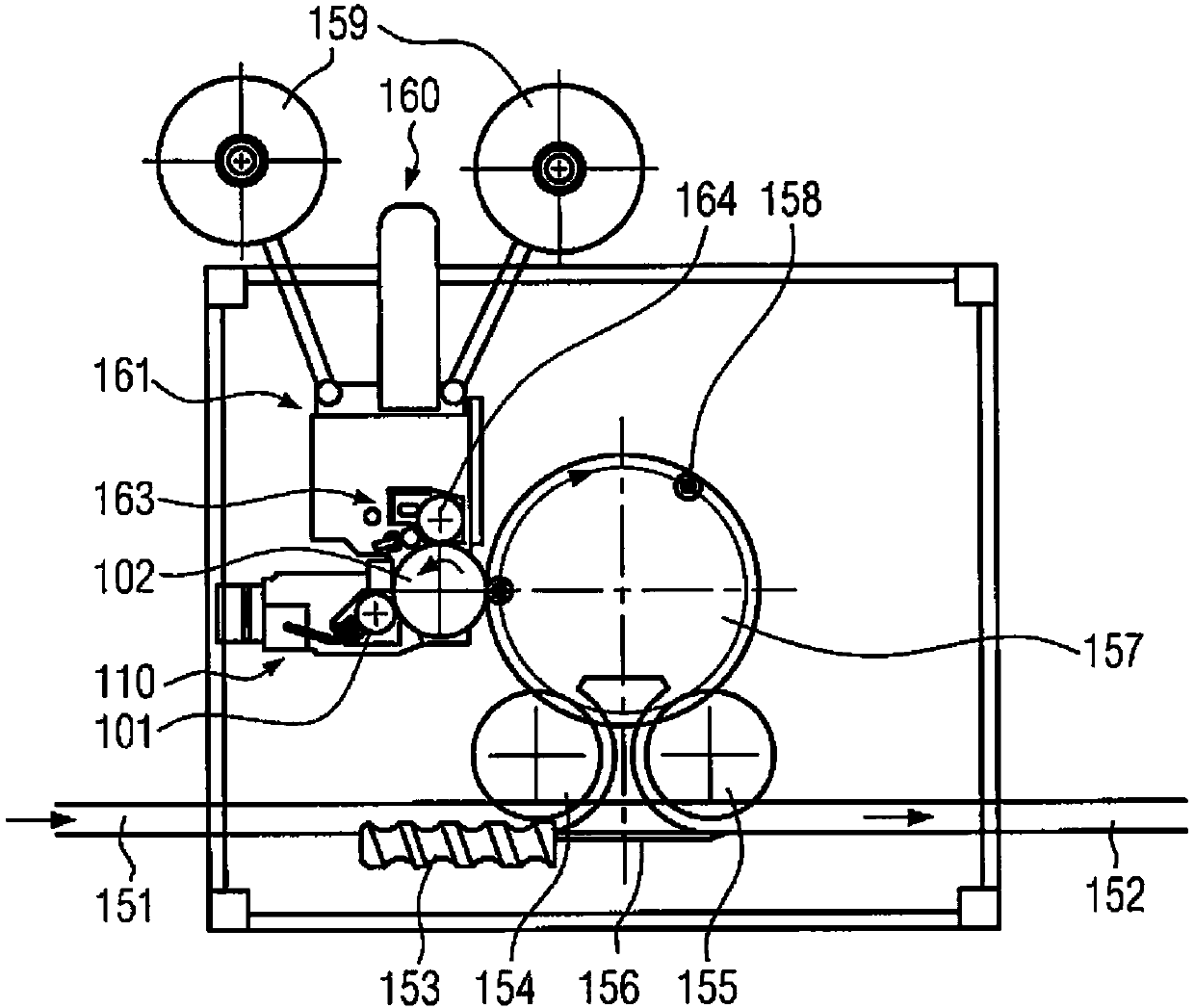

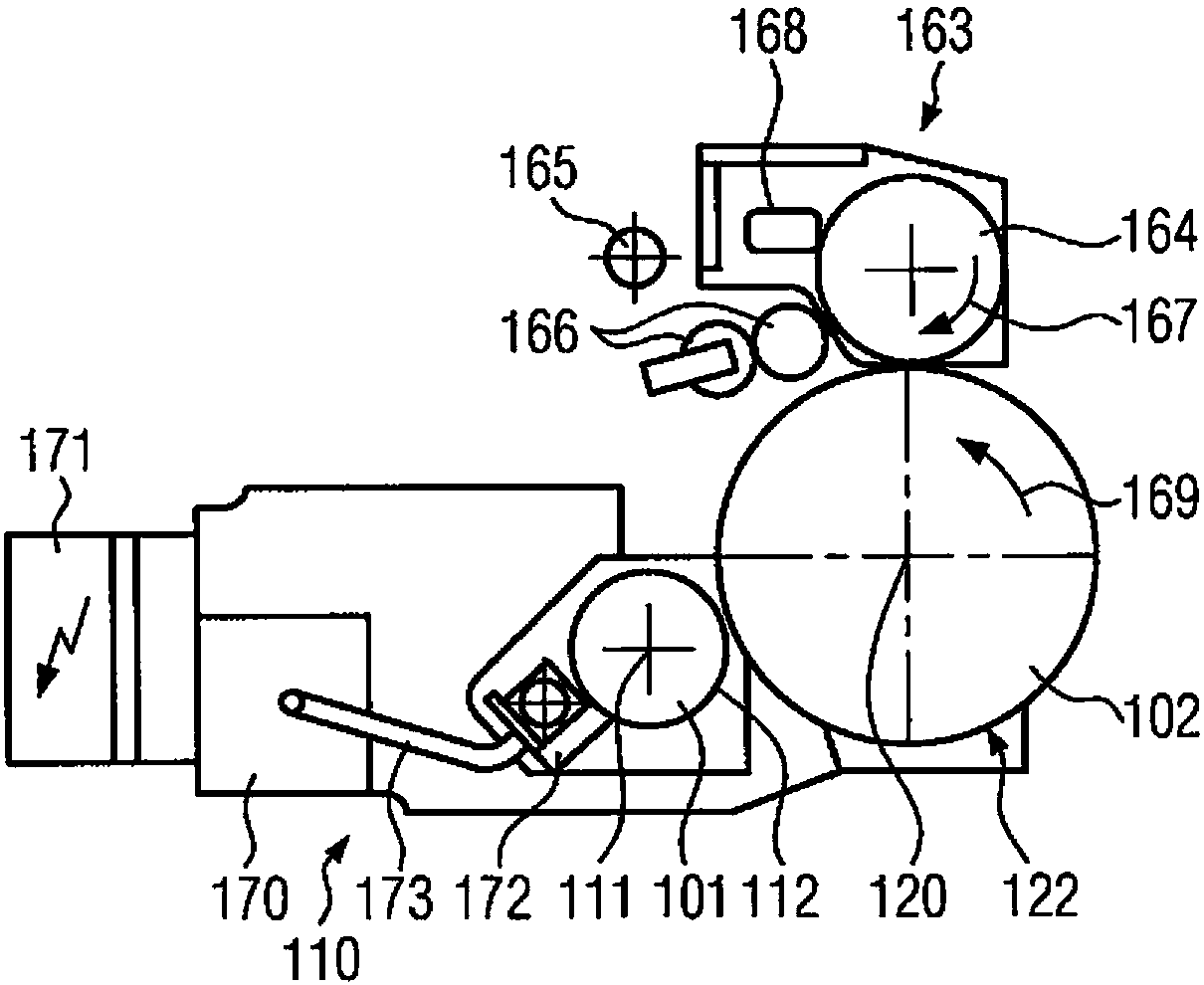

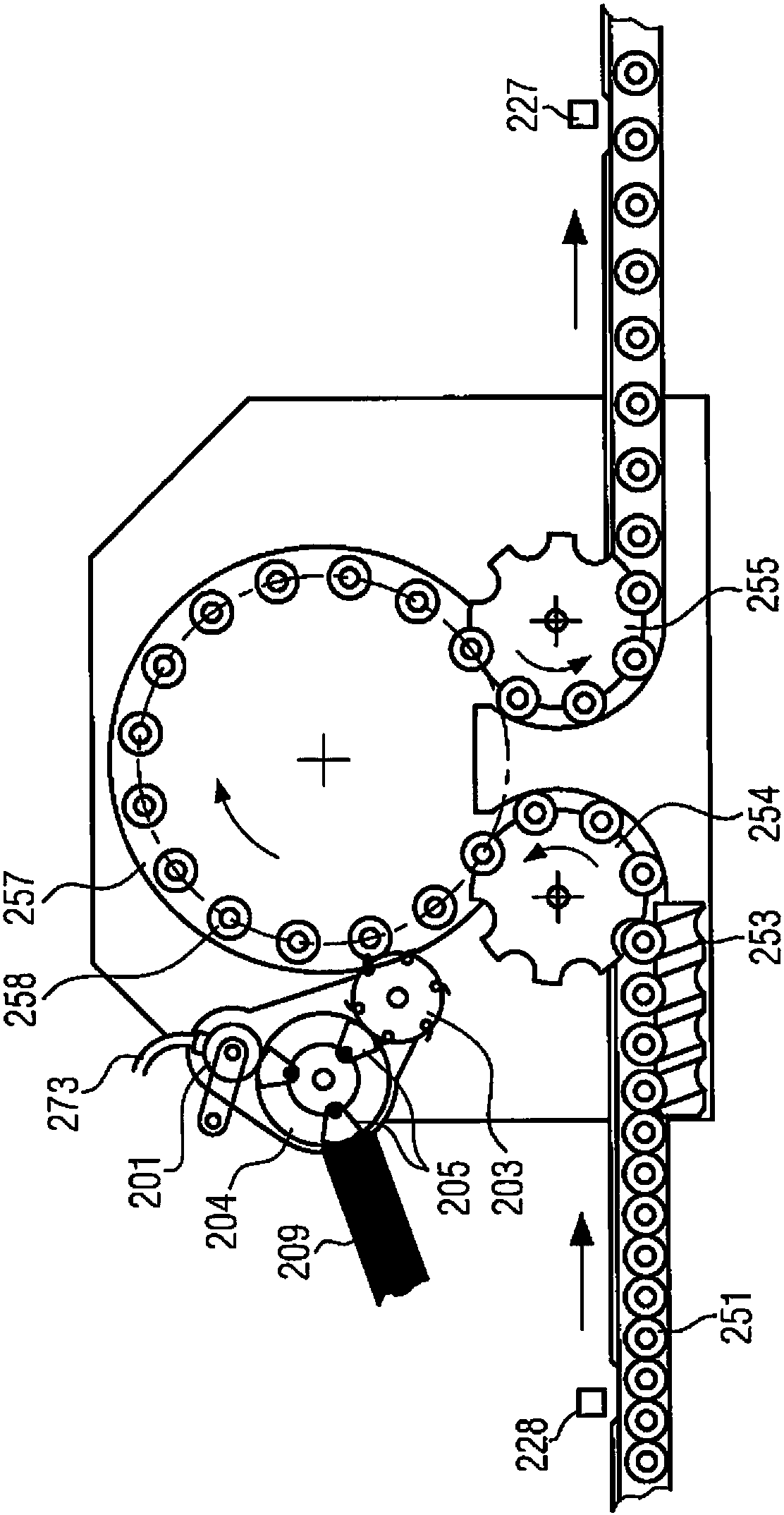

[0054] Figure 1a A schematic top view of a labeling device is shown, in which glue is applied directly from a glue roller to the labels. Figure 1b shown in Figure 1a Detail view of gluing machine. The shown labeling device has the following elements known from the prior art: an input device 151 for continuously conveying the containers to be labeled; an inlet star wheel 154 with an upstream dispensing screw 153; a guide arc 156 ; a rotating disk 157 with a plurality of rotating disks 158 arranged at equal distances on a common partial circle; an outlet star wheel 155 and an outlet star line 152 for ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com