Automatic releasing device for pilot-controlled check valve

A hydraulically controlled one-way valve and automatic unloading technology, which is applied in mining equipment, earthwork drilling, pillars/supports, etc., can solve problems such as waste and pollution of the underground environment, and achieve the effect of automatic pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

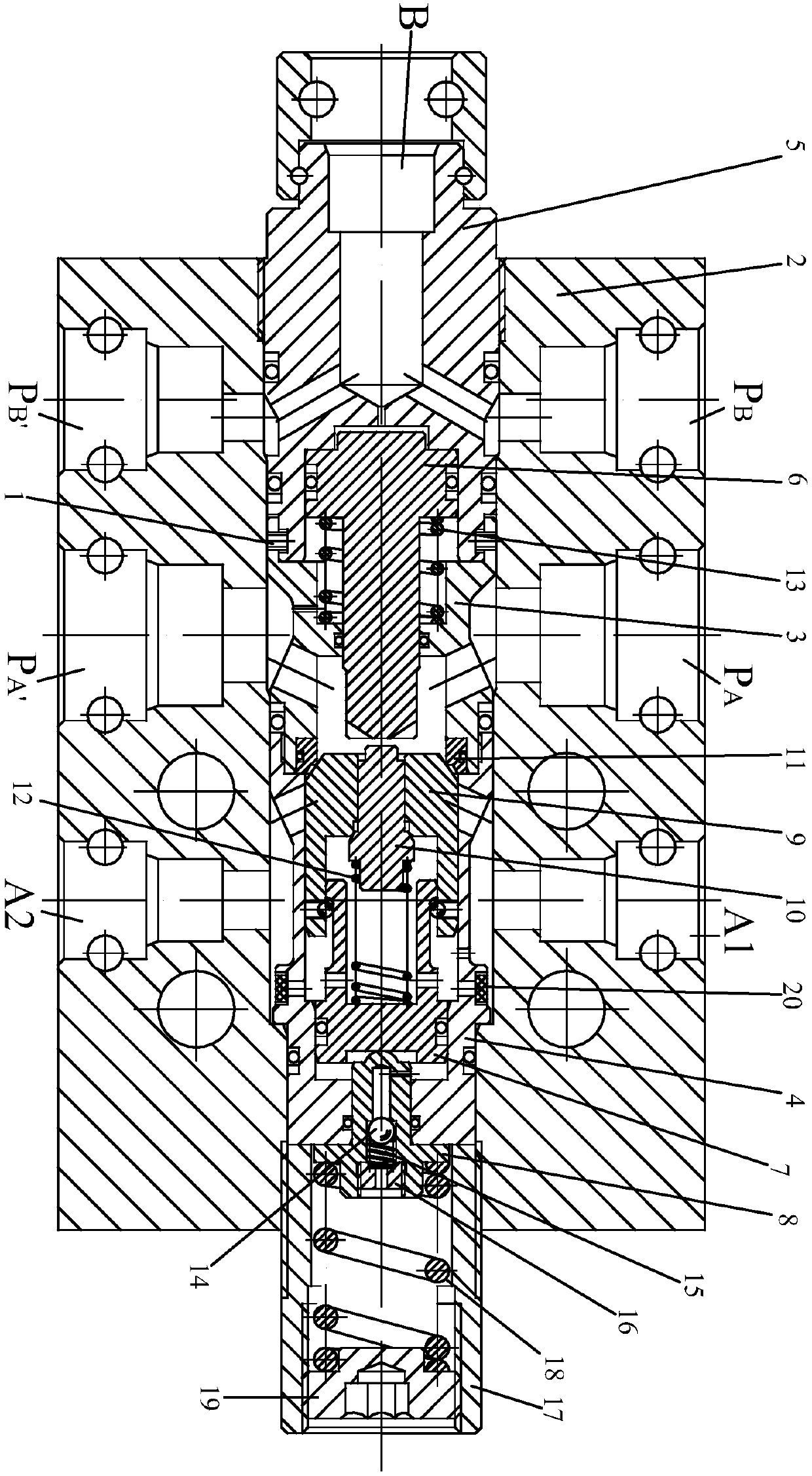

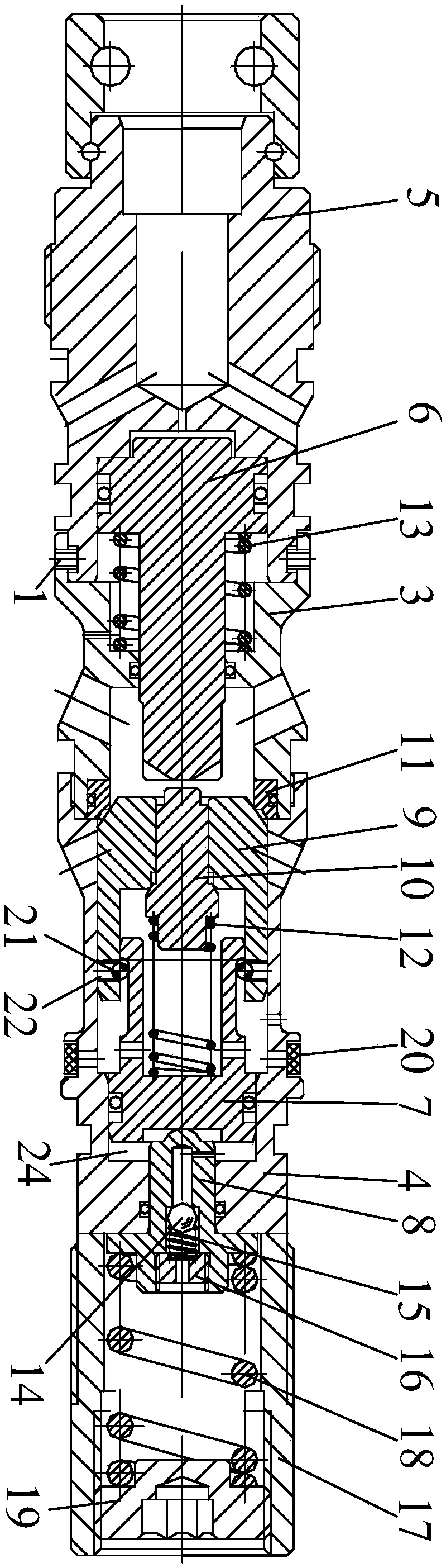

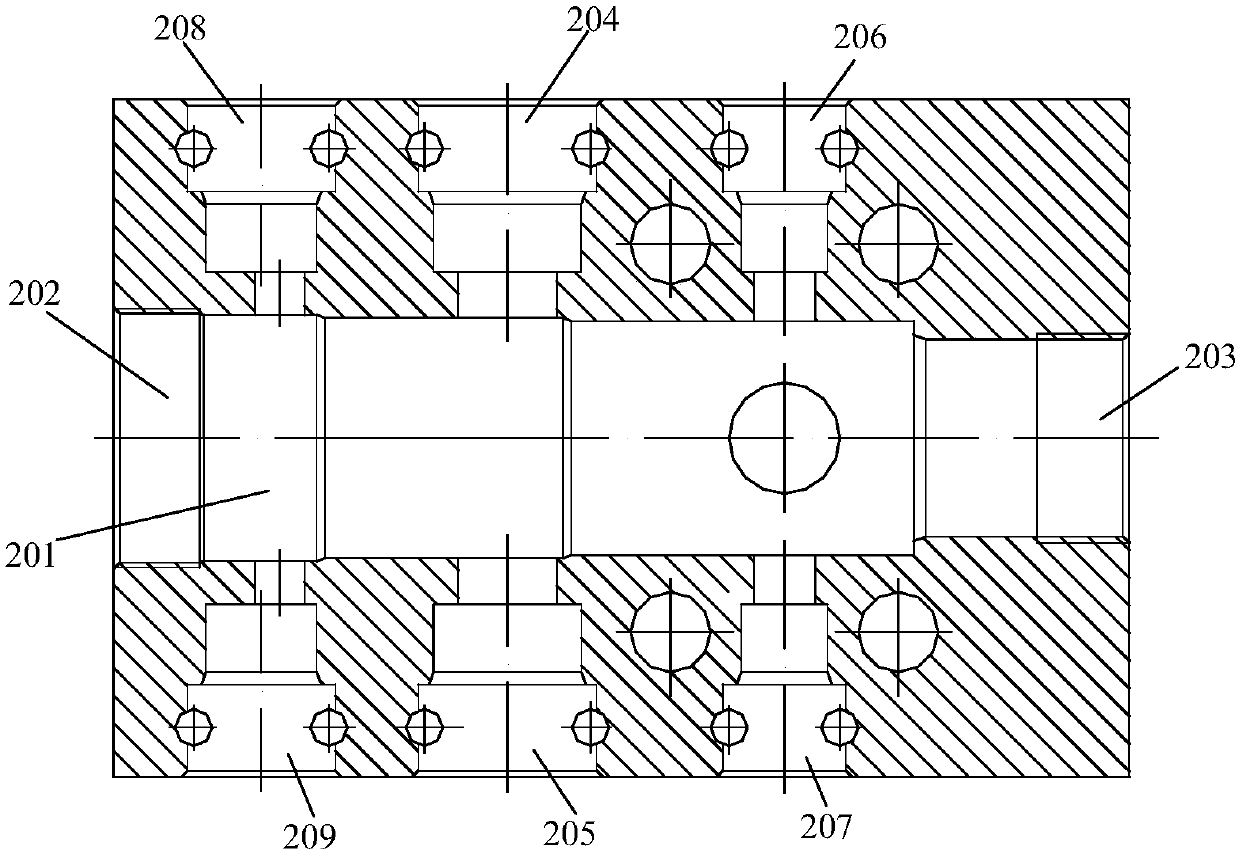

[0042] The following describes the specific implementation of the present invention in further detail through the description of the embodiments with reference to the accompanying drawings. The purpose is to help those skilled in the art have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and Contribute to its implementation.

[0043] Such as Figure 1 to Figure 15 As shown, it is an automatic unloading hydraulic control check valve, including a valve body 2, an ejector rod, a screw sleeve 5, an inlet sleeve, a valve seat 11, a second spring 13, a pressure regulating mechanism and the automatic unloading device of the present invention, The automatic unloading device of the hydraulic control check valve of the present invention includes a valve sleeve 4, a choke sleeve 20, a first spring 12, a large valve core 9 arranged inside the valve sleeve 4, and a small valve core arranged inside the large valve core 9 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com