Multi-cone, multi-stage spray nozzle

A technology for spray nozzles and nozzles, which is applied to spray devices, spray devices, lighting and heating equipment, etc., and can solve problems such as limited adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

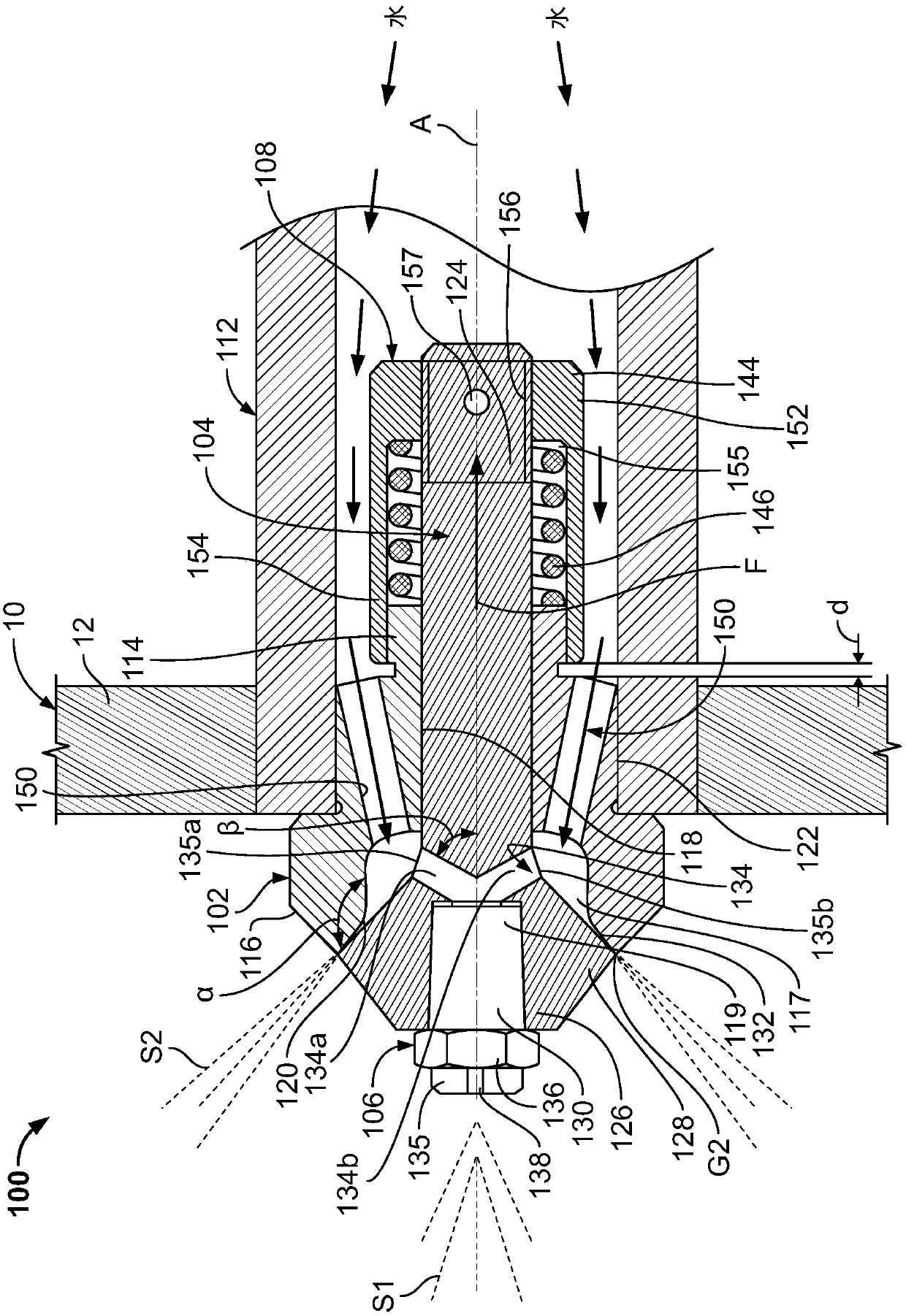

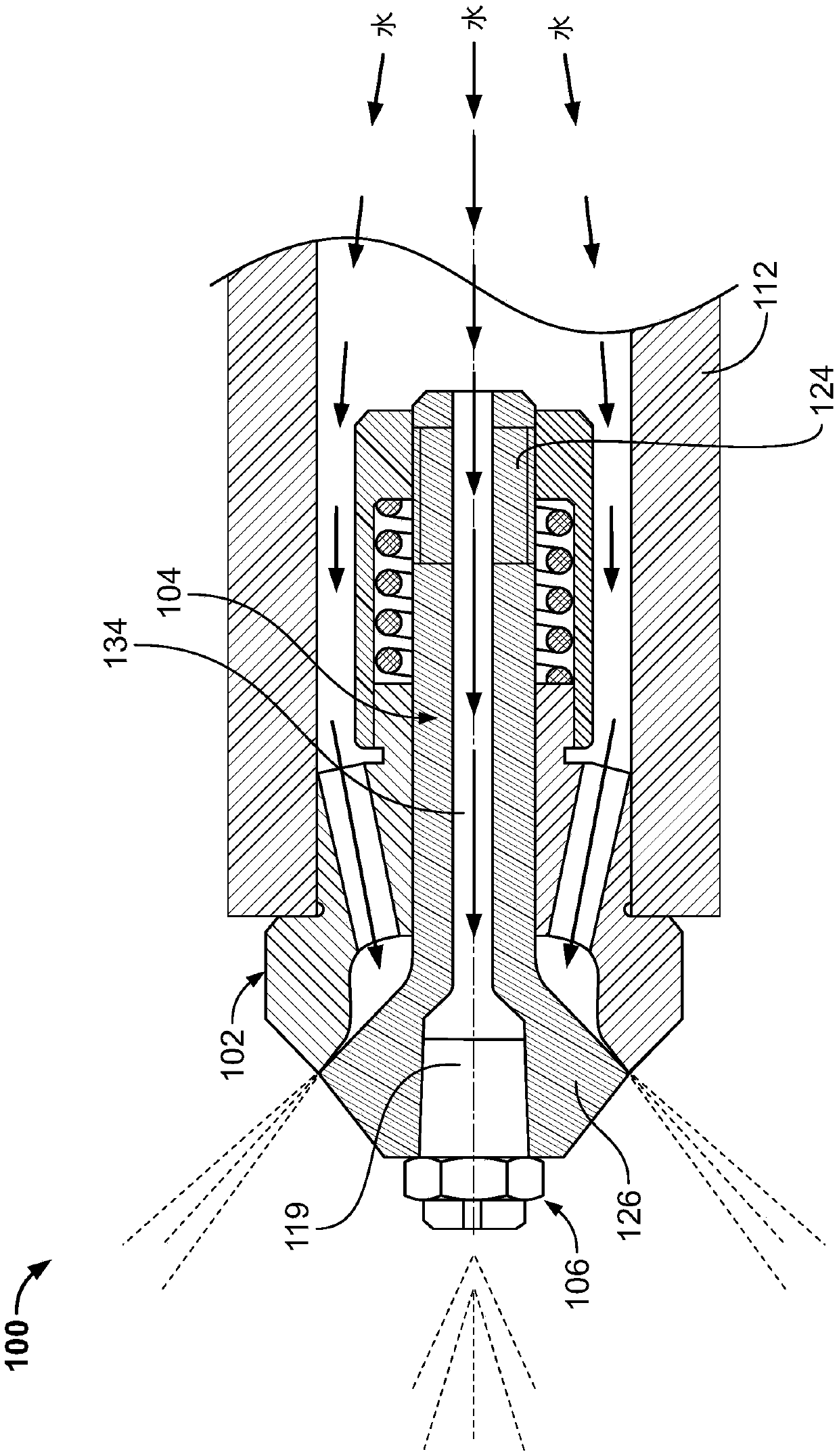

[0018] The present disclosure is directed to an injection nozzle typically used in steam conditioning applications such as desuperheaters and steam conditioning valves, although other applications are contemplated. In disclosed embodiments, the spray nozzle includes two or more stages of operation for accommodating an increasing range of cooling fluid operating pressures and flow rates through the nozzle. Two or more stages are achieved by implementing two or more valve heads with different operating sensitivities.

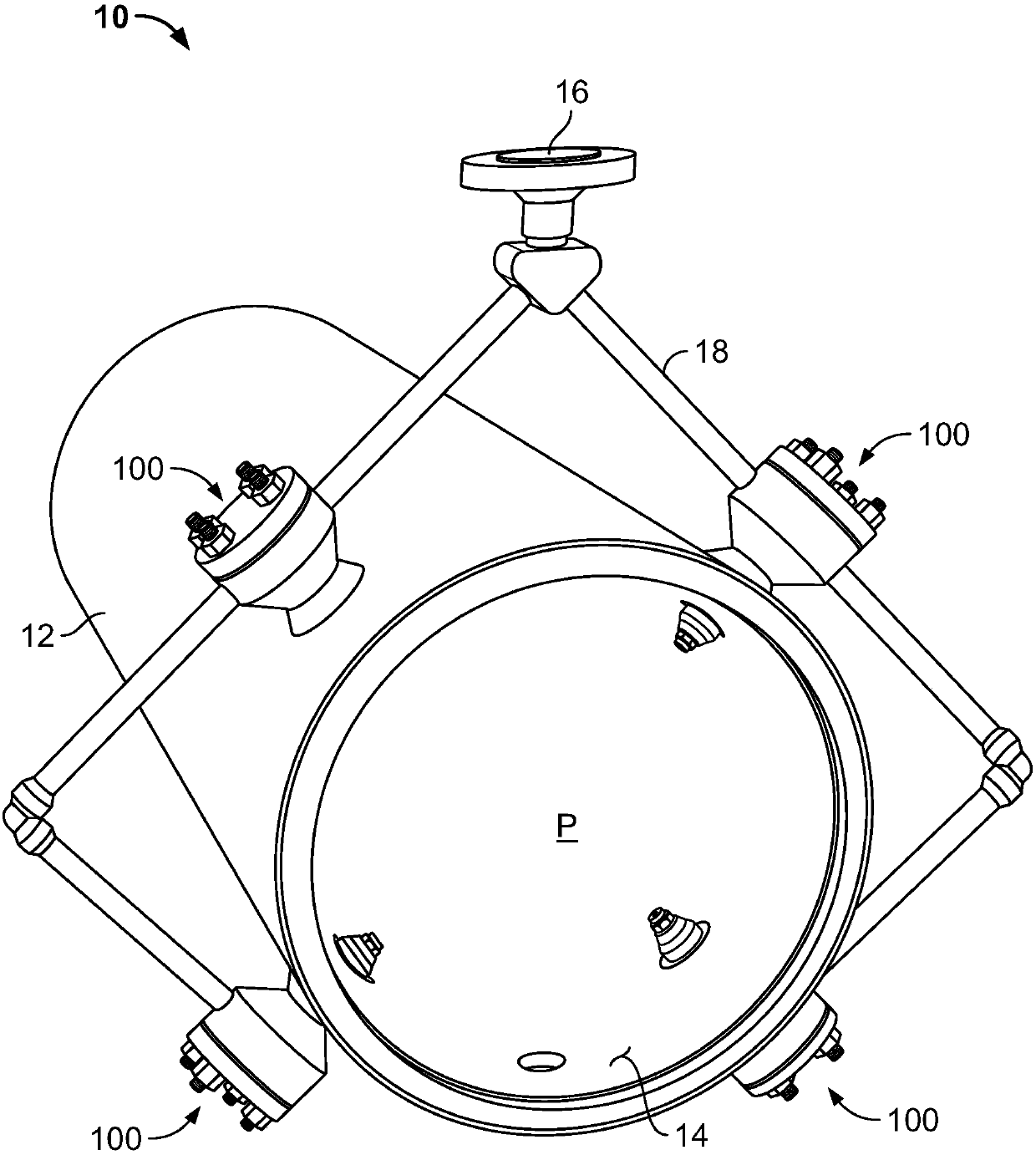

[0019] figure 1 Depicted is a steam tube 10 comprising a plurality of injection nozzles 100 constructed in accordance with the present disclosure. Generally, steam pipe 10 may be used to reduce the temperature of superheated steam traveling therein to a desired set point temperature. For example only, figure 1 The steam pipe 10 can be a desuperheater (for example, TBX-T desuperheater, TBX desuperheater, DMA / AF desuperheater, or DMA / AF-HTC desuperheater)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com