Self-tightening round tube hoop tension testing device capable of keeping curvature of round tube

A hoop tensile and testing device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems affecting the accuracy of the measurement, the complexity of the testing device, etc., to achieve convenient installation, ensure accuracy, maintain The effect of round tube curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

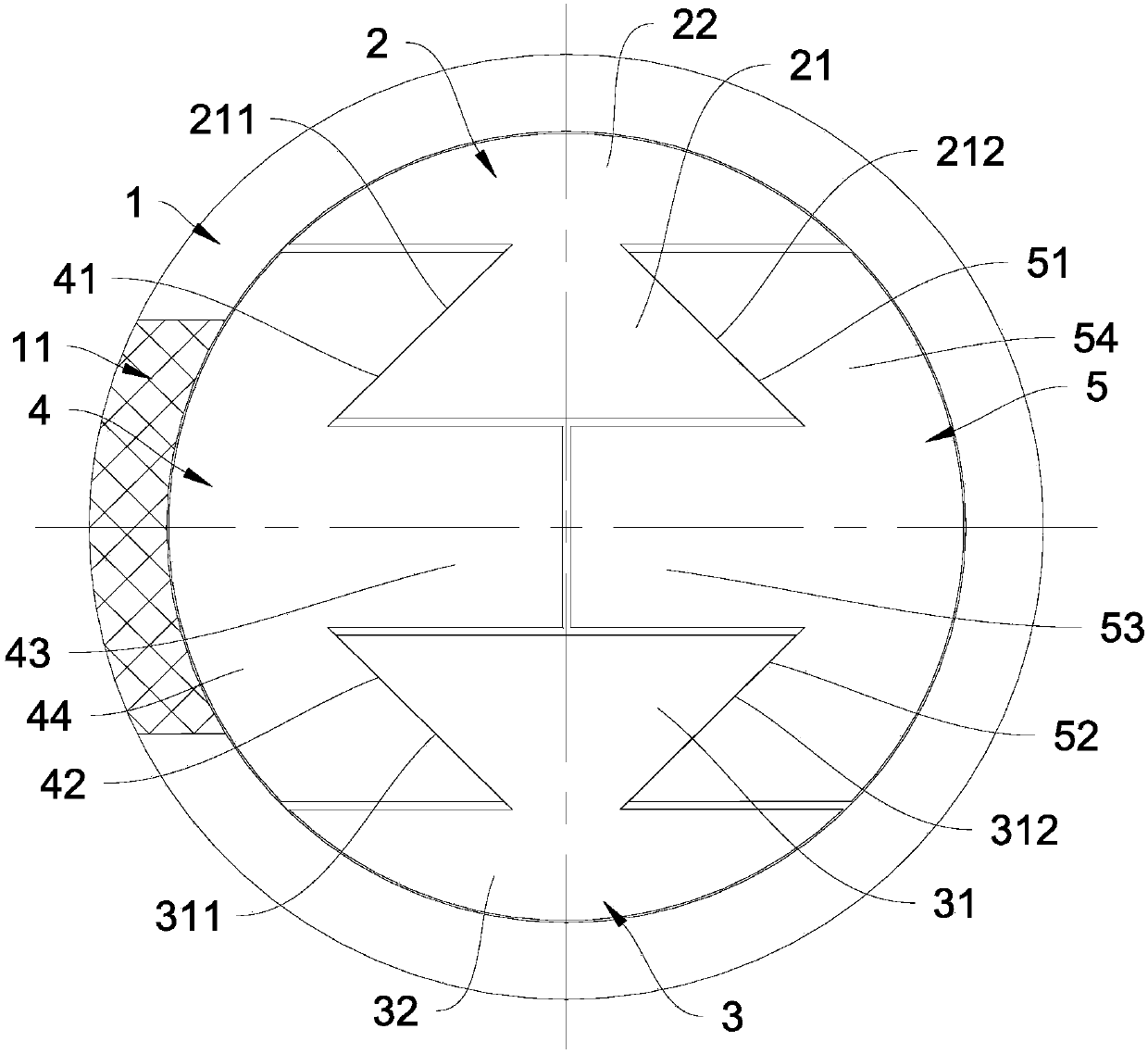

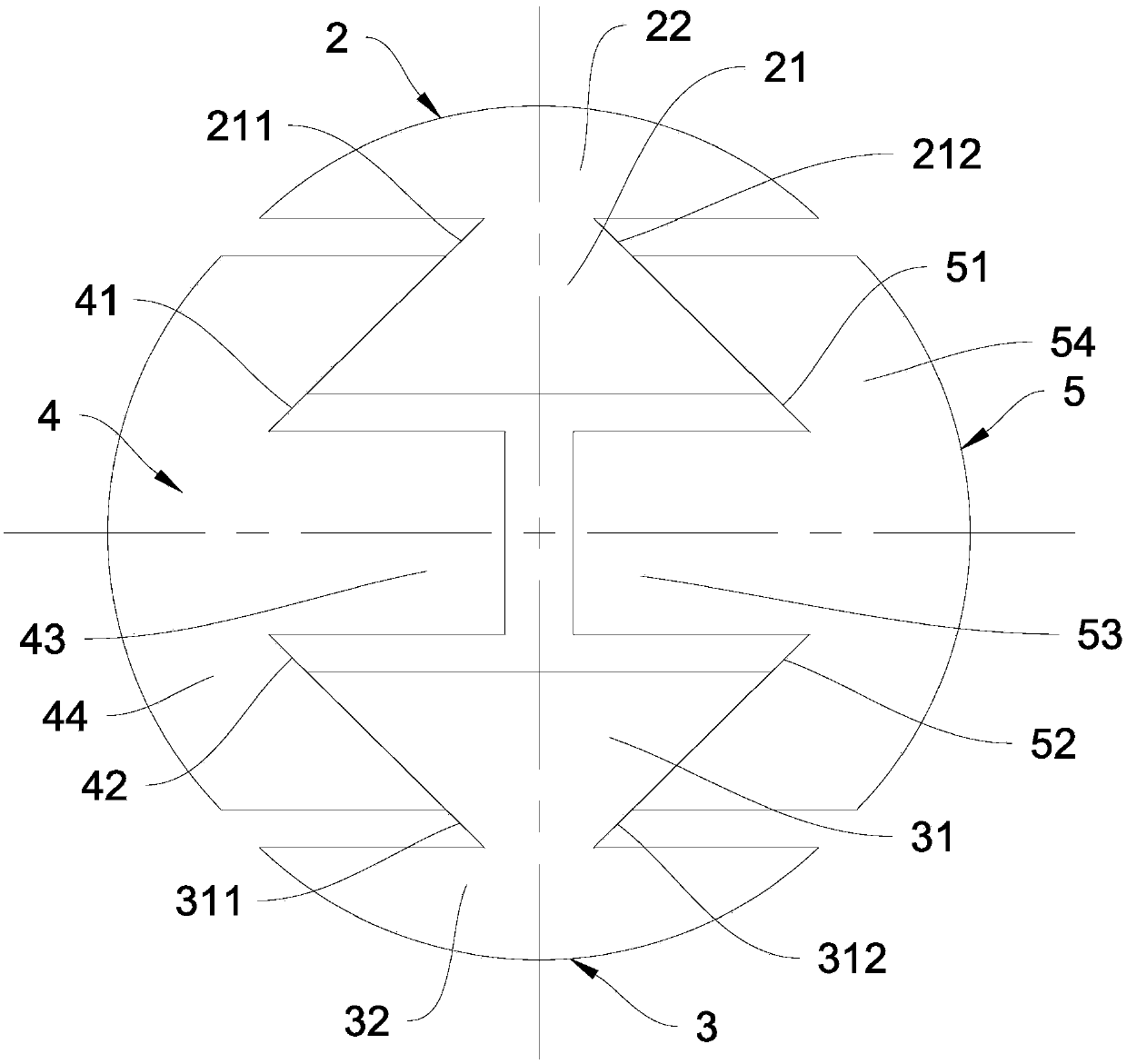

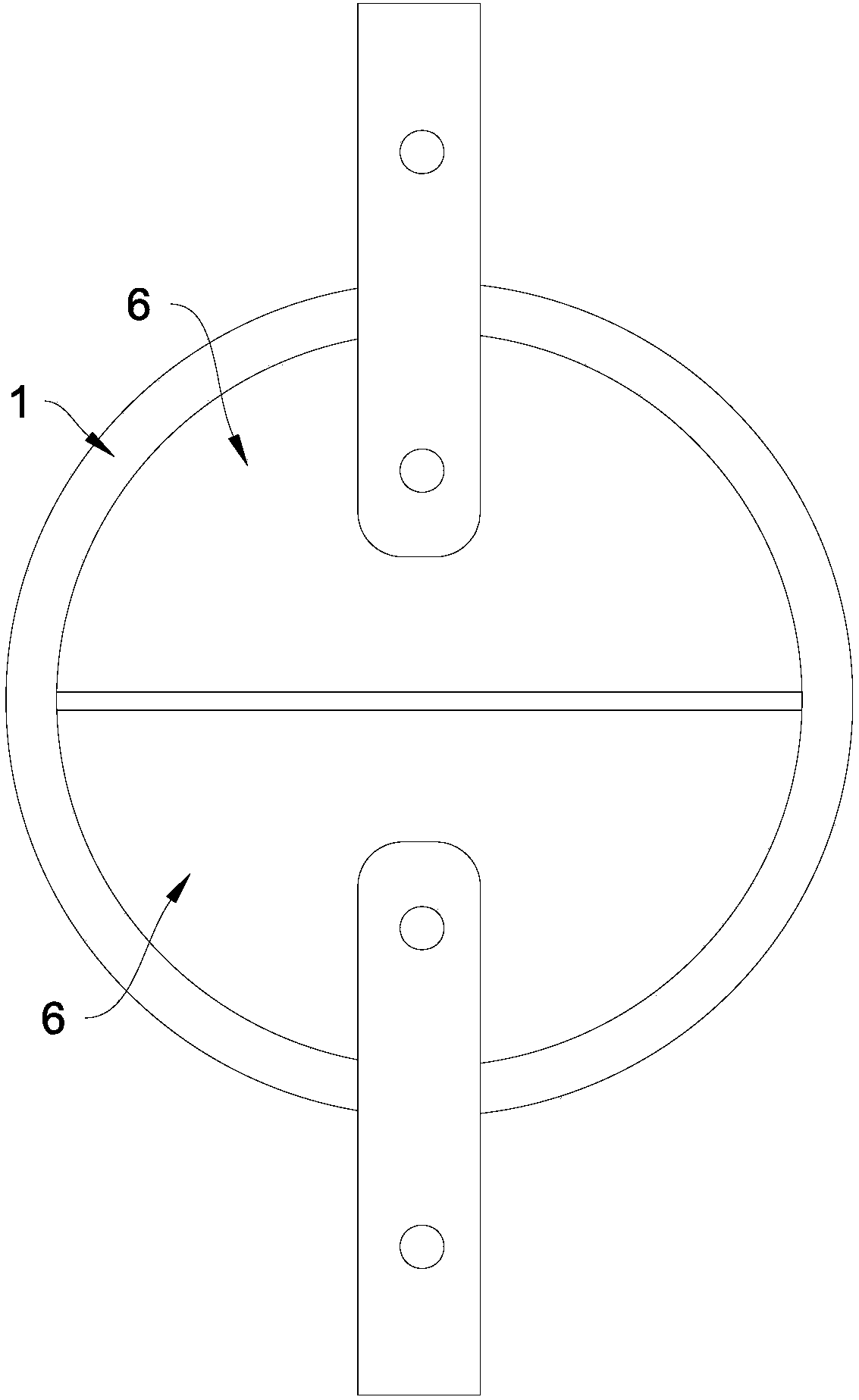

[0035] Such as figure 1 , figure 2 As shown, in a preferred embodiment of the present invention, the self-tightening circular tube circumferential tensile test device for maintaining the curvature of the circular tube includes a first separation disc 2, a second separation disc 3, The third separation disc 4, the fourth separation disc 5.

[0036] The first separation disc 2 and the second separation disc 3 are arranged oppositely, and the third separation disc 4 and the fourth separation disc 5 are arranged oppositely. The spliced outer ring of the first separation disc 2, the second separation disc 3, the third separation disc 4, and the fourth separation disc 5 forms a cylindrical surface structure matching the inner wall sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com