Conveying device

A technology of a handling device and a supply device, which is applied to tires, other household appliances, household appliances, etc., and can solve problems such as difficult transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

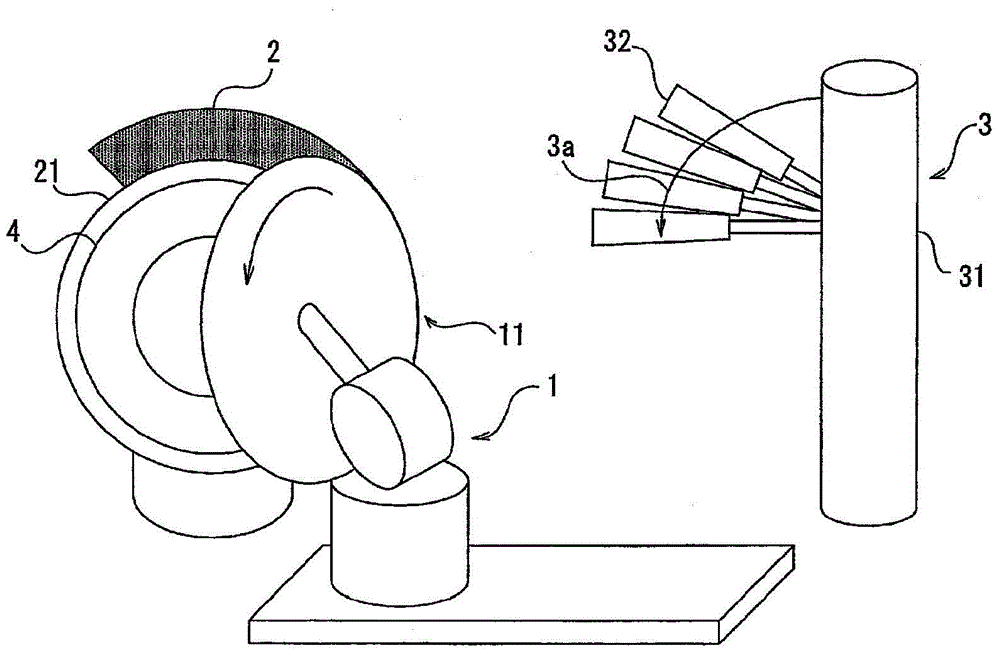

[0048] (1) The rotary table 11 can also be as Figure 7 The disc shape shown. At this time, the outer peripheral side of the disc serves as the mounting surface. If the rotary table 11 is in the shape of a disc, preferably, the pillars 31 are suspended from above, so that the rotary table 11 does not interfere with the pillars 31 of the roller conveyor 3 at the receiving position.

[0049] (2) In the above-mentioned embodiment, although the roller conveyor 3 was shown as an example of a supply apparatus, it is not limited to this. For example, it is also possible to directly supply the bent rubber member 2 by using an extruder capable of extruding the rubber member 2 in a bent state.

[0050] (3) Moreover, in the above-mentioned embodiment, the roller conveyor 3 which conveys the rubber member 2 from top to bottom was shown as an example of a supply apparatus. However, the roller conveyor 3 may convey the rubber member 2 from bottom to top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com