Touch panel preparation method, touch panel and touch device

A touch panel and touch device technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve the problem that high-end products cannot be widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

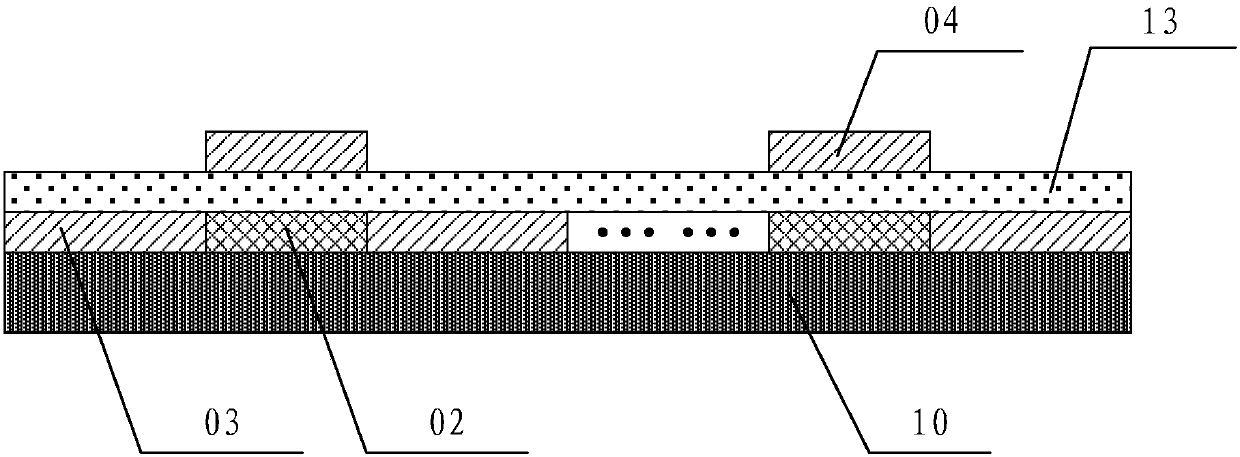

[0047] In one embodiment of the present invention, refer to figure 1 , showing a schematic cross-sectional structure of a touch panel, which may include: a substrate 10 and a first metal layer patterned on the substrate 10; wherein the first metal layer includes a first touch electrode area 03, and the signal wiring area and the redundant wiring area between the adjacent first touch electrode area 03; the insulating layer 13 covering the first metal layer; the second metal layer formed on the insulating layer 13 , the second metal layer includes a second touch electrode area 04 , the orthographic projection of the second touch electrode area 04 on the substrate 10 overlaps the orthographic projection of the signal wiring area and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com