Steel brace anti-falling method in SMW construction method pile fencing structure foundation pit

A technology of enclosure structure and steel support, which is applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problems of falling steel support and affecting the safety of construction personnel on site, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

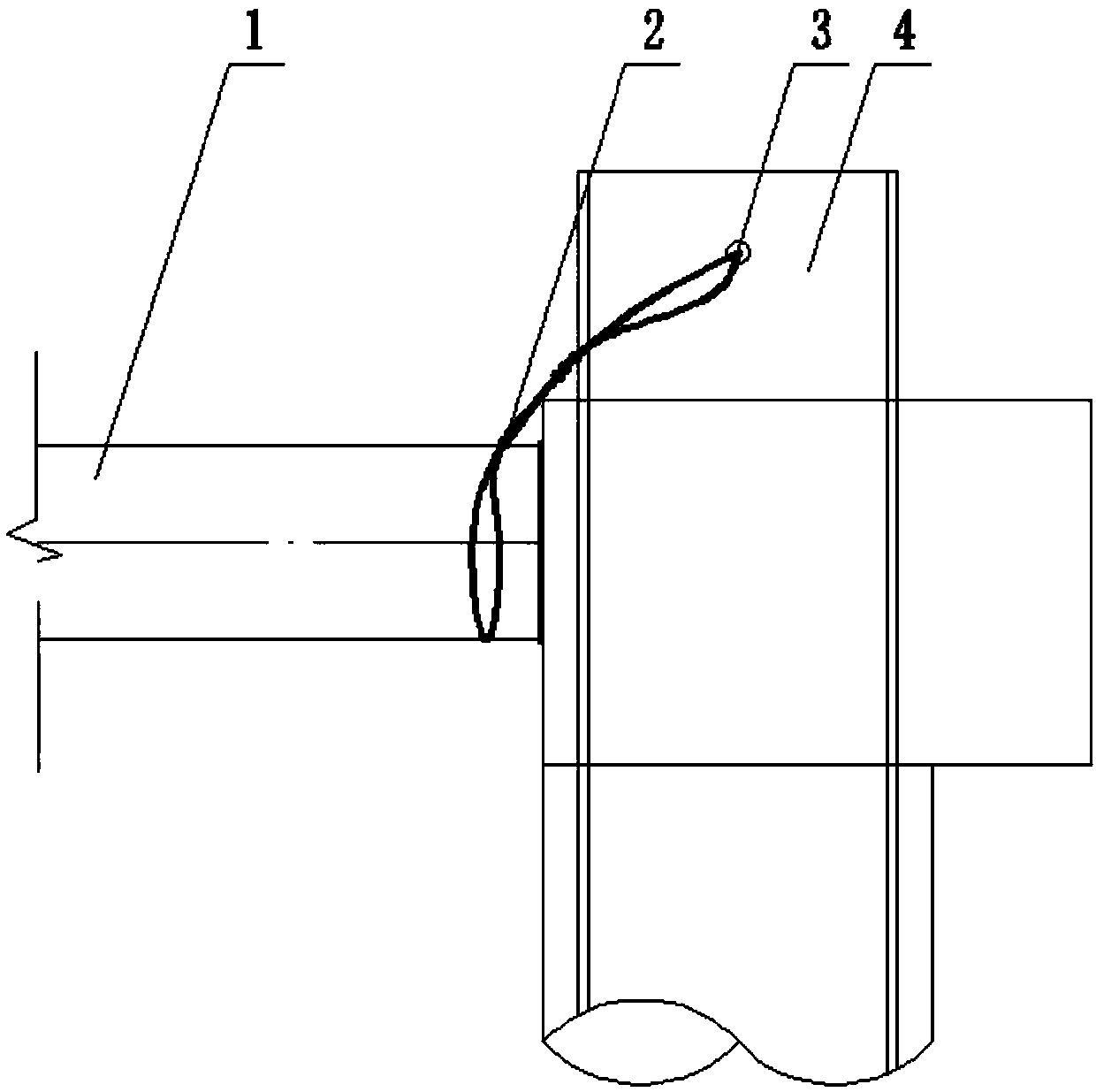

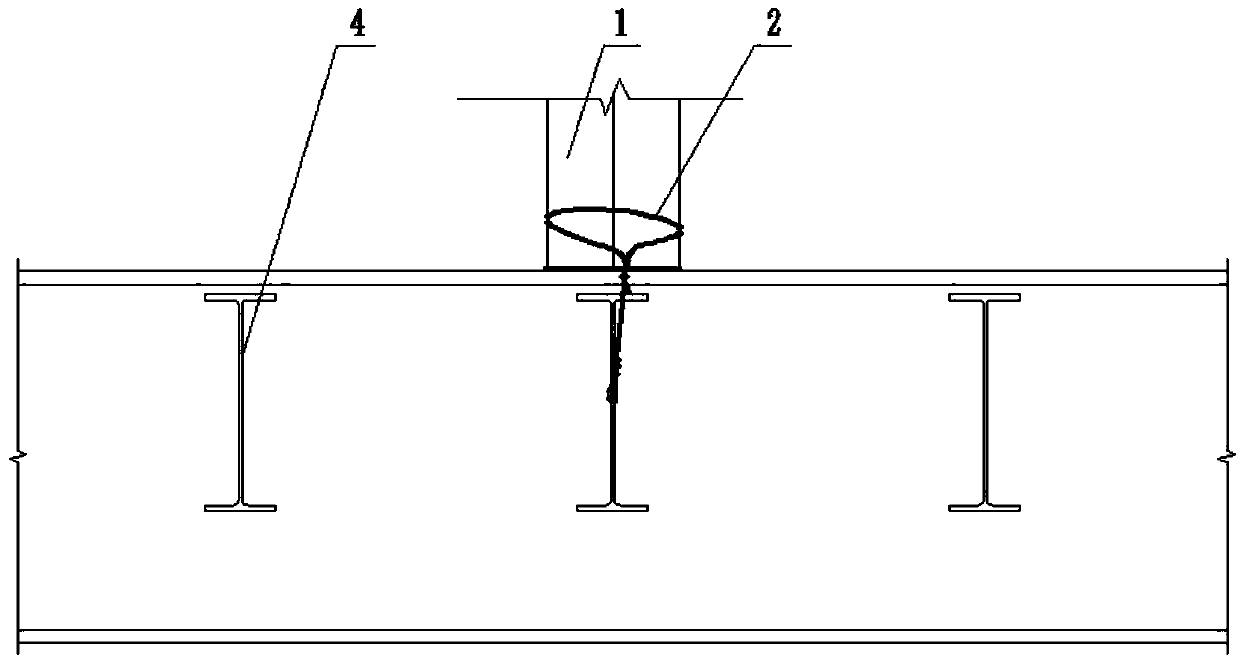

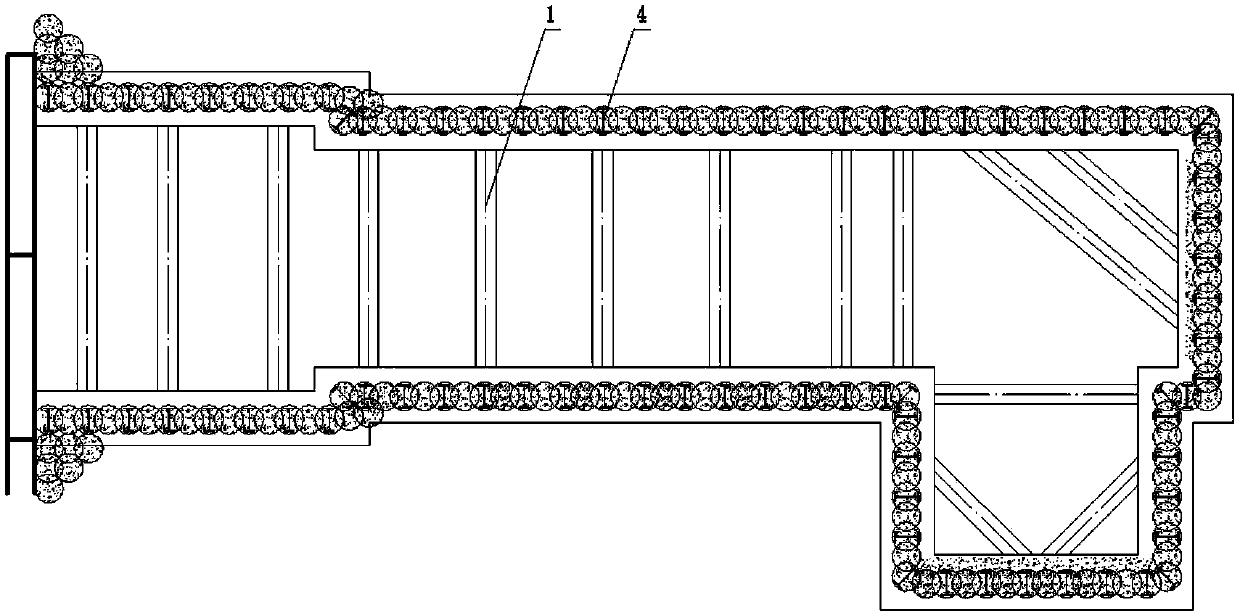

[0016] A method for preventing falling of a steel support in a foundation pit of an SMW pile enclosure structure, in which a steel wire rope 2 is connected between the end of a steel support 1 and the hoisting hole 3 of an adjacent H-shaped steel 4 . The specific construction steps are as follows:

[0017] (1) The installation of steel support is in accordance with the requirements of the design drawings, and is installed at the position of the welded support on the embedded part of the crown beam position, and the prestress is applied according to the design requirements. stable system.

[0018] (2) After the construction of the SMW construction method pile is completed, there is a hoisting hole fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com