A wrecker platform mechanism with adjustable panel length

A wrecker and flatbed technology, which is applied to vehicles used for freight, vehicles used for emergency repairs, and motor vehicles, etc., can solve problems such as low operation safety, improve safety, improve lifting quality, and expand range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

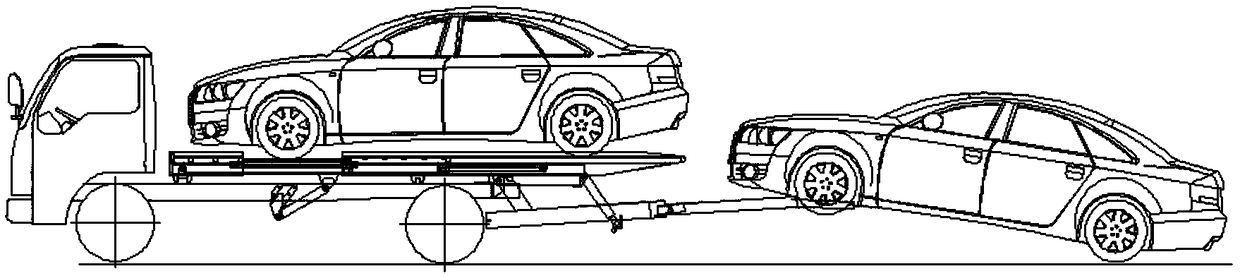

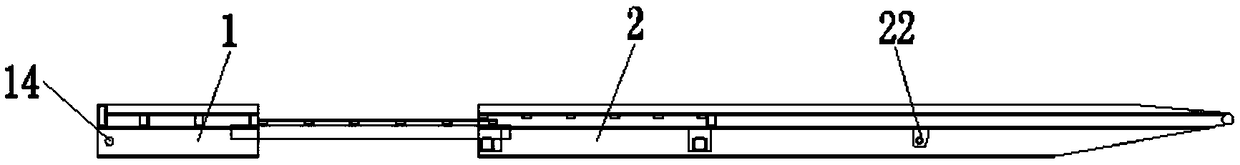

[0032] Such as Figure 1-Figure 8 As shown, the panel mechanism of the wrecker vehicle with adjustable panel length of the present invention includes a front panel 1, a rear panel 2, a subframe 3, an inclined cylinder 4, a panel telescopic cylinder 5, a lifting mechanism 6 and a lifting cylinder 7, wherein:

[0033] The tail end of the front plate 1 is connected with the front end of the rear plate 2 through the fixed lock pin 8. When the fixed lock pin 8 is inserted into the front plate 1 and the rear plate 2 at the same time, the front plate 1 and the rear plate 2 can be connected together to form a whole; When the fixed lock pin 8 is released, the front plate 1 and the rear plate 2 are in a separated state; the bottom of the front plate 1 has a first guide rail channel beam 11 oppositely arranged, and the bottom of the rear plate 2 has a second guide rail channel beam 21 oppositely arranged. Two longitudinal beams 31 parallel to each other are arranged on the surface of the...

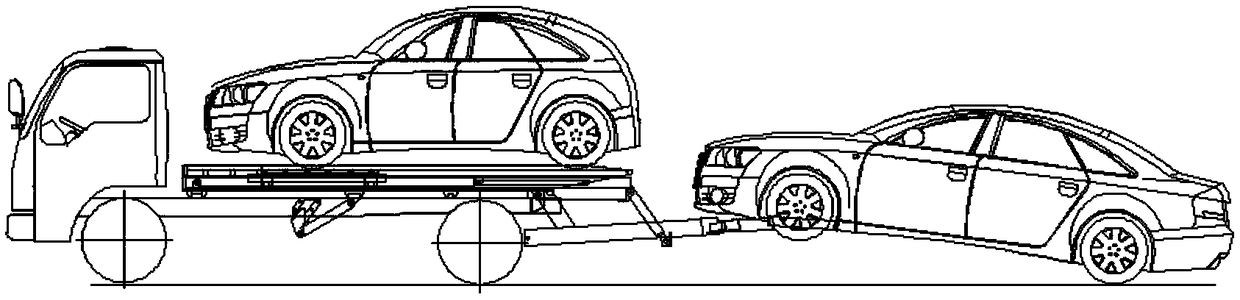

Embodiment 2

[0060] Such as Figure 9-Figure 10 As shown, the difference from Embodiment 1 is that the rear plate 2 includes a long plate 23 and a short plate 24, and the long plate 23 and the short plate 24 are connected together by a hinge shaft. The second guide rail groove beam 21 breaks away from the longitudinal beam 31 in the subframe 3, and the short plate 24 will naturally form a fold with the long plate 23 after touching the ground, forming an angle with each other. The ground forms the working angle A2, and the platform working angle A2 is much smaller than A1, which is more suitable for low vehicles to safely get on the platform; the rest is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com