NMP recovery and purification system and recovery and purification method thereof

A cooler and chilled water technology, which is applied to the device for coating liquid on the surface, organic chemistry, coating, etc., can solve the problems of increasing the degree of risk and increasing the burden of the company, and achieve the effect of reducing the use and reducing the burden of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

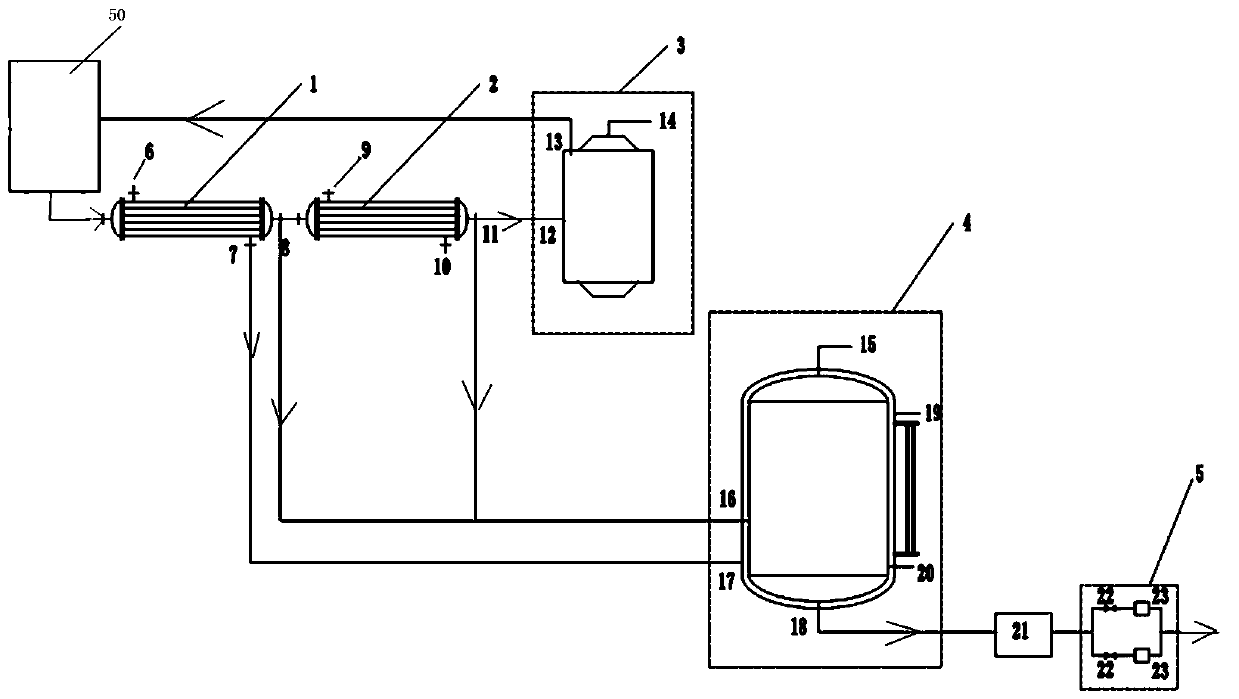

[0019] Such as figure 1 , a NMP recovery and purification system, the whole system of the present invention is a closed cycle, including cooling water cooler 1, chilled water cooler 2, recovery unit 3, rectification unit 4, final purification unit 5. The cooling water cooler 1, the chilled water cooler 2, and the recovery unit 3 are sealed and communicated in sequence.

[0020] The cooling water cooler 1 is provided with a cooling water inlet 6, a cooling water outlet 7, and an NMP liquid outlet A8.

[0021] The chilled water cooler 2 is provided with a chilled water inlet 9, a chilled water outlet 10, and an NMP liquid outlet B11.

[0022] The recovery unit 3 is provided with an NMP waste gas inlet 12 , an NMP return air outlet 13 and a discharge outlet 14 .

[0023] The rectification unit 4 is provided with a water vapor discharge port 15 , an NMP liquid inlet 16 , a heating medium inlet 17 , an NMP liquid outlet C18 , a heating medium outlet 19 , and a vacuum port 20 .

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap