Method and device for distributing operation and maintenance work order

An operation and maintenance and work order technology, applied in the Internet field, can solve problems such as low operation and maintenance efficiency, and achieve the effect of improving operation and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

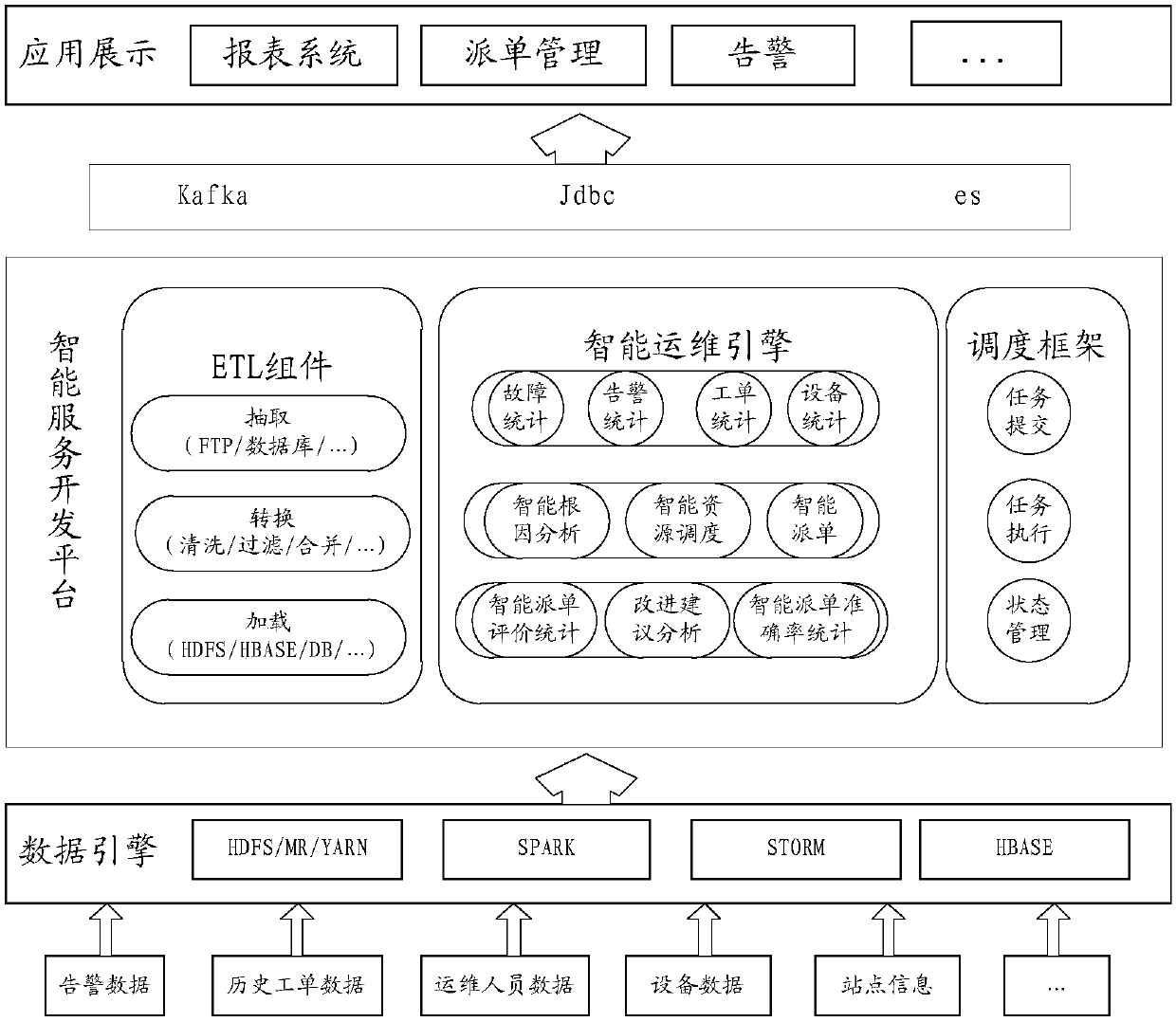

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

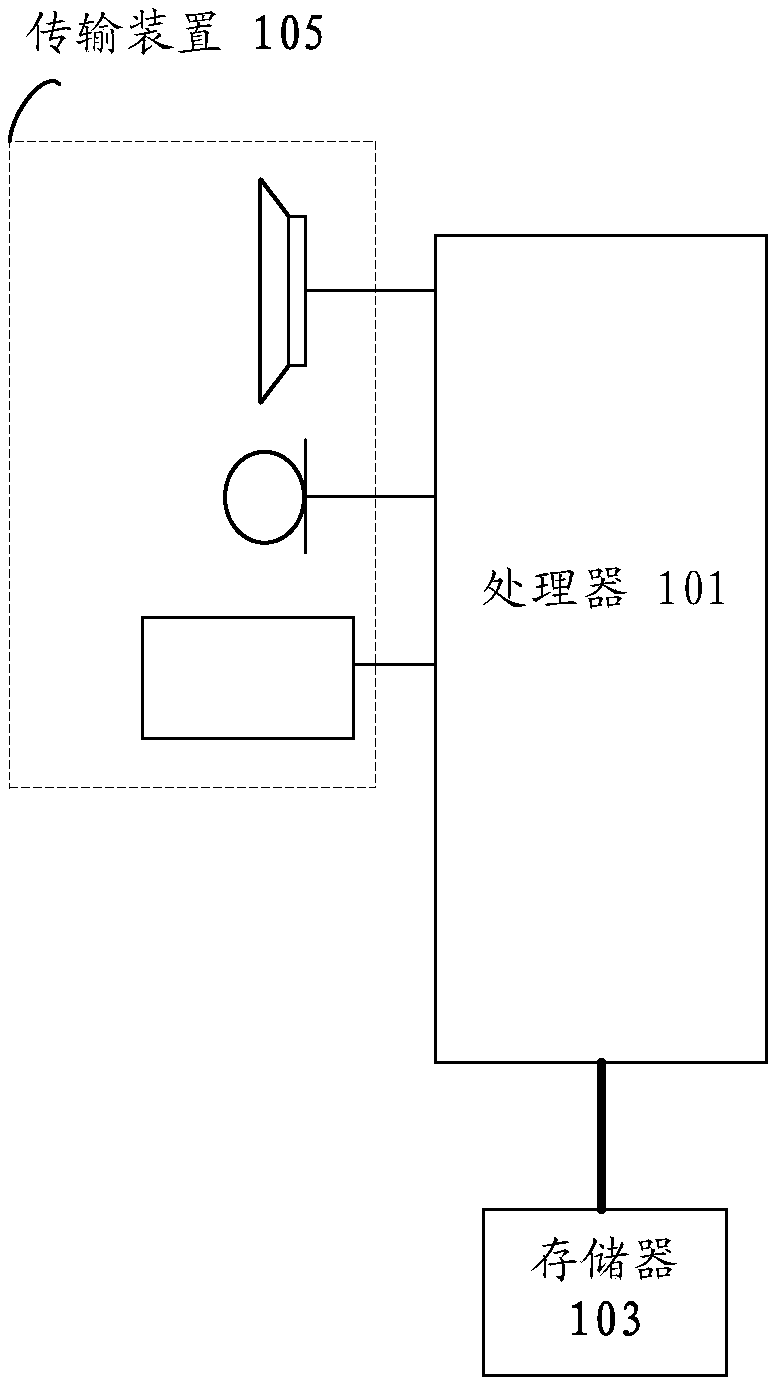

[0019] The method embodiment provided in Embodiment 1 of the present application may be executed in a mobile terminal, a computer terminal, or a similar computing device. Take running on a computer terminal as an example, such as figure 1 As shown, the computer terminal may include one or more (only one is shown in the figure) processors 101 (the processors 101 may include but not limited to processing devices such as microprocessor MCU or programmable logic device FPGA, etc.), for storing Data storage 103, and transmission means 105 for communication functions. Those of ordinary skill in the art can understand that, figure 1 The shown structure is only for illustration, and it does not limit the structure of the above-mentioned electronic device.

[0020] The memory 103 can be used to store software programs and modules of application software, such as program instructions / modules corresponding to the control method of the device in the embodiment of the present invention, ...

Embodiment 2

[0137] The embodiment of the present invention also provides a device for allocating operation and maintenance work orders. The device is used to implement the above-mentioned embodiments and preferred implementation modes, and what has been described will not be repeated. As used below, the term "module" may be a combination of software and / or hardware that realizes a predetermined function. Although the devices described in the following embodiments are preferably implemented in software, implementations in hardware, or a combination of software and hardware are also possible and contemplated.

[0138] Image 6 is a schematic diagram of an operation and maintenance work order distribution device according to an embodiment of the present invention. Such as Image 6 As shown, the device may include: a first determining unit 61 , a second determining unit 62 and an allocating unit 63 .

[0139] The first determining unit 61 is configured to determine the fault type of the f...

Embodiment 3

[0154] The embodiment of the invention also provides a storage medium. Optionally, in this embodiment, the above-mentioned storage medium may be configured to store program codes for performing the following steps:

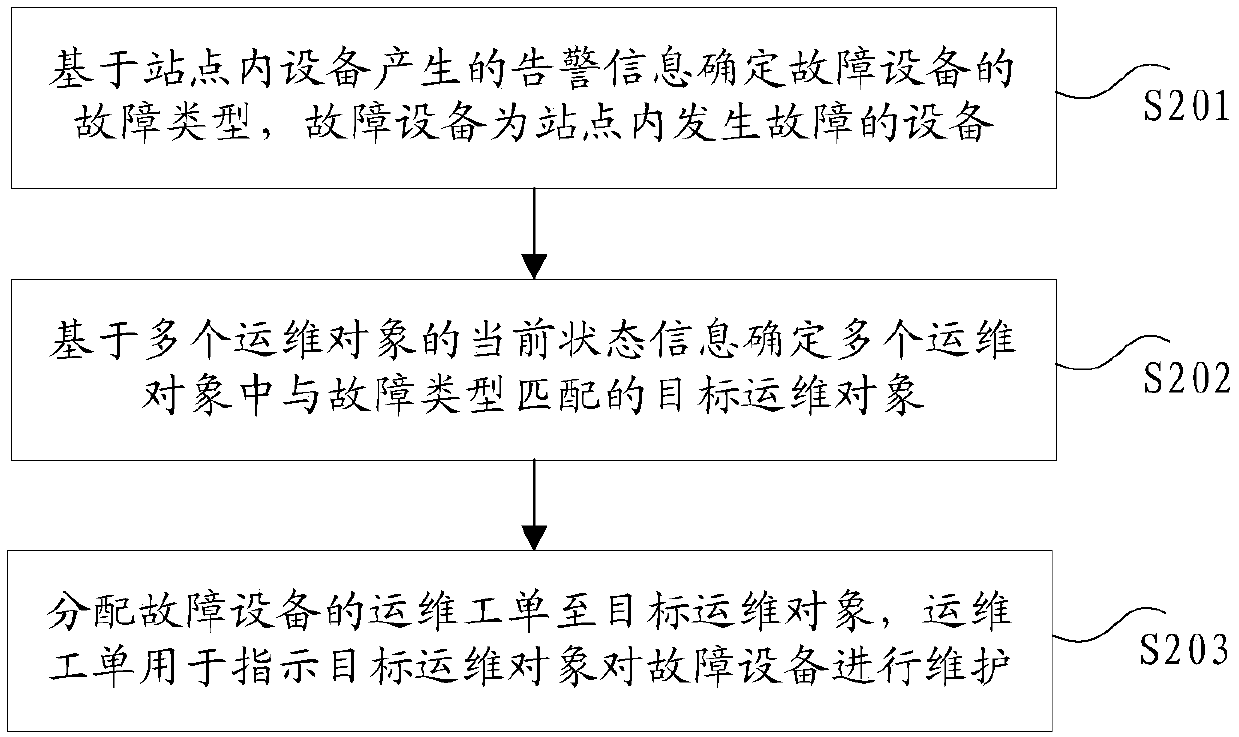

[0155] S51. Determine the fault type of the faulty device based on the alarm information generated by the equipment in the site, where the faulty device is a faulty device in the site;

[0156] S52. Determine a target operation and maintenance object among the multiple operation and maintenance objects that matches the fault type based on the current state information of the multiple operation and maintenance objects;

[0157] S53. Distribute the operation and maintenance work order of the faulty device to the target operation and maintenance object, wherein the operation and maintenance work order is used to instruct the target operation and maintenance object to maintain the faulty device.

[0158] Optionally, in this embodiment, the above-mentioned storage med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com