Coil spring glue laying device for sunshade curtain

A technology of sunshade and coil spring, applied in the field of sunroof sunshade, can solve problems such as offset of glue laying position, coil spring is easy to spread, bakelite deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

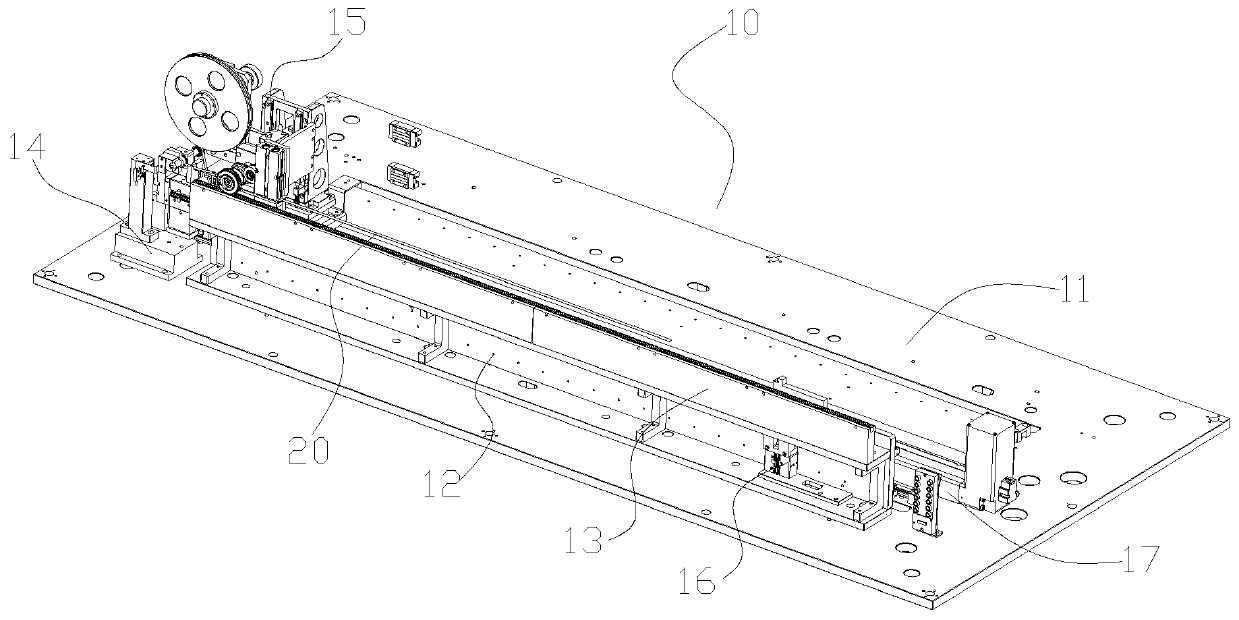

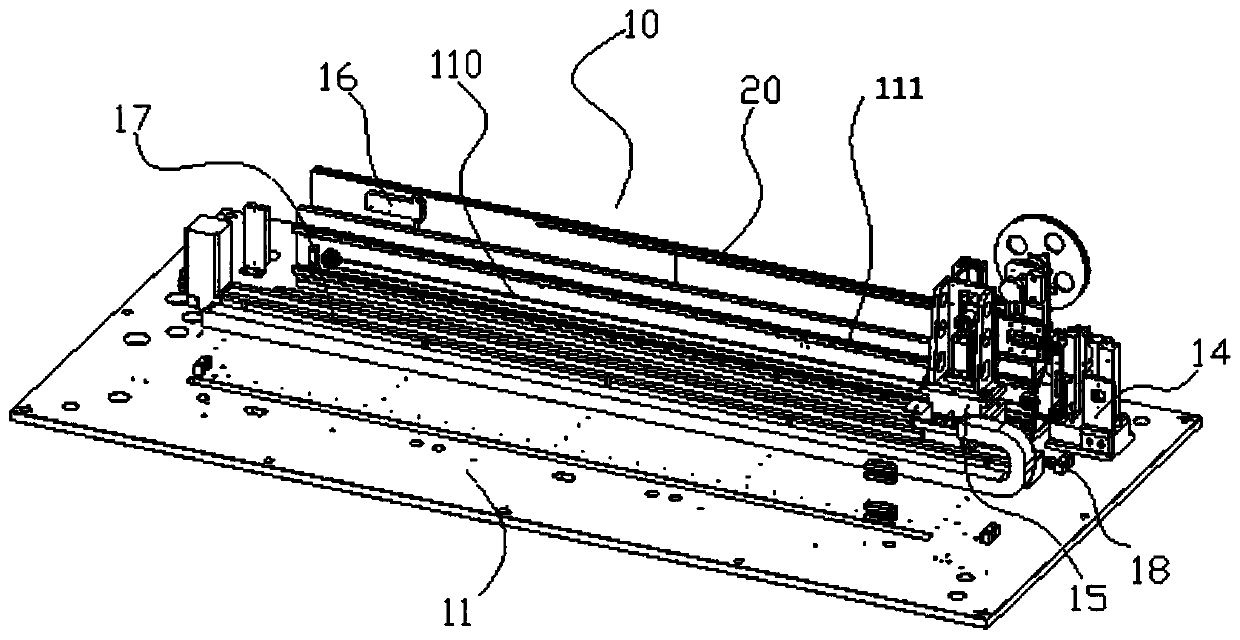

[0040] Such as figure 2 , 3 As shown, the present invention provides a coil spring gluing device 10 for a sunshade, comprising: a device base plate 11 and a rack 13 mounted on one side of the device base plate 11 through a rack frame 12, the rack One end of the 13 is provided with a coil spring unwinding and clamping mechanism 14, away from the coil spring unwinding and clamping mechanism 14, and the side of the rack 13 at the other end is provided with a rear end electrode mechanism 16; close to the coil spring unwinding clamp Tightening mechanism 14, the side of the rack 13 is provided with a double-wheel glue spreading mechanism 15, and the double-wheel glue spreading mechanism 15 is installed on the bottom plate 11 of the device through an electric linear slide 17 and a glue spreading guide rail 18. The rubber-laying guide rail 18 and the rack 13 are parallel to each other; the two-wheel rubber-laying mechanism 15 is provided with a rubber-laying wheel 1519 and a frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com