Oil tank transporting and installing integrated device

A technology of oil tanks and lifting devices, which is applied in the directions of transportation and packaging, hoisting devices, lifting equipment braking devices, etc. It can solve the problems of large volume, vertical hoisting of the bridge crane in the main factory building, and no installation conditions for oil tank equipment, etc. problems, to achieve the effect of simple operation, no safety risk, and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

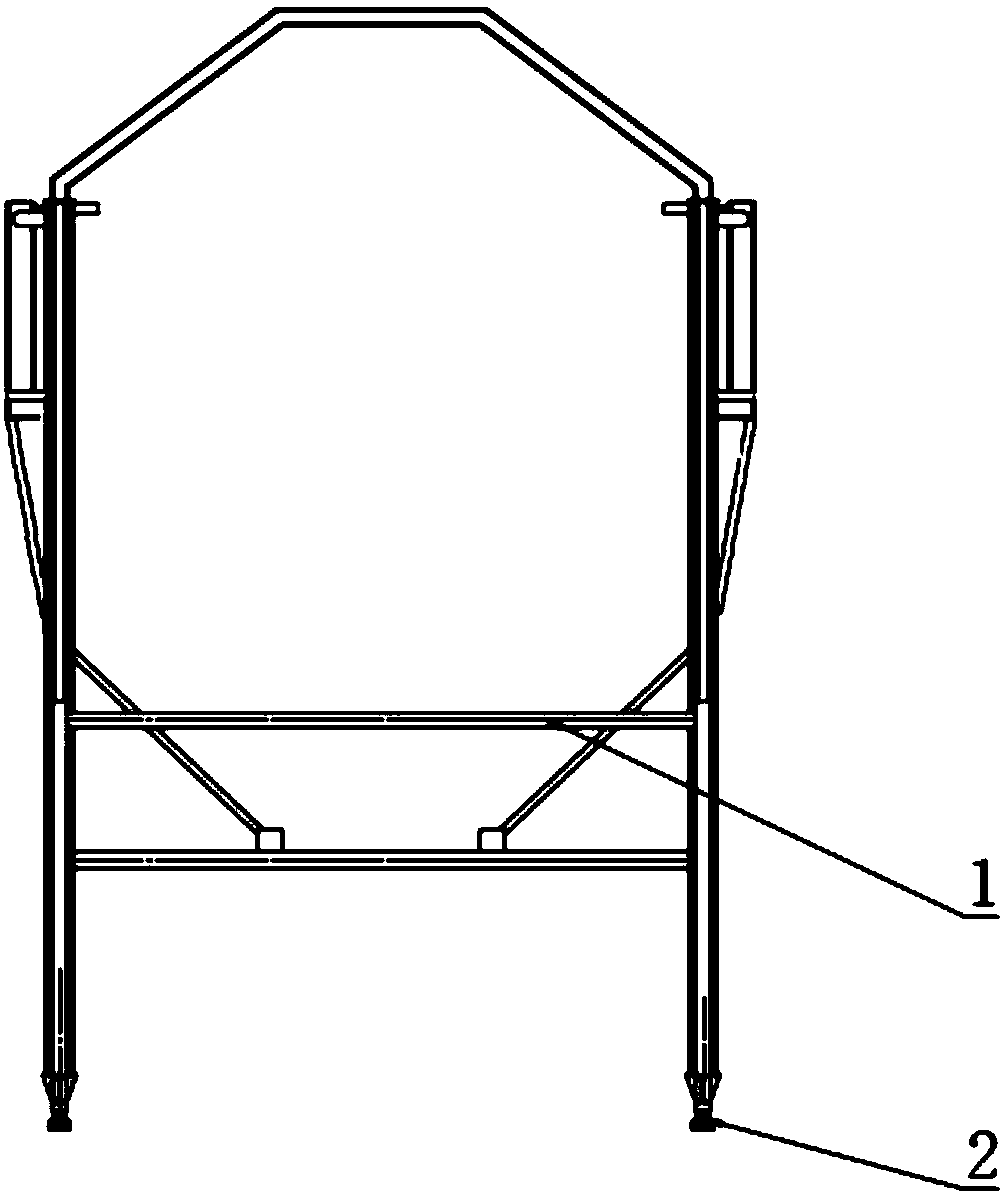

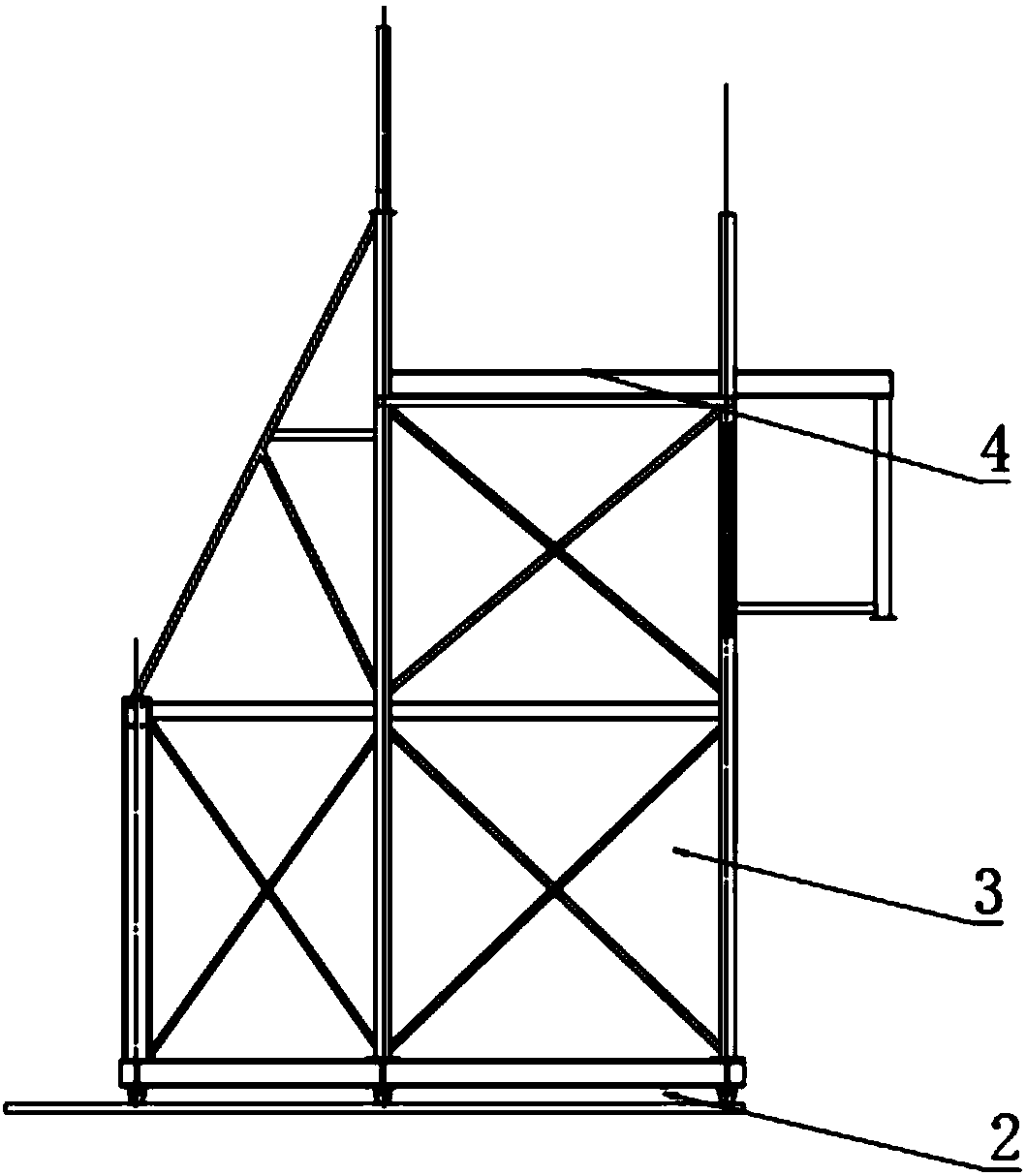

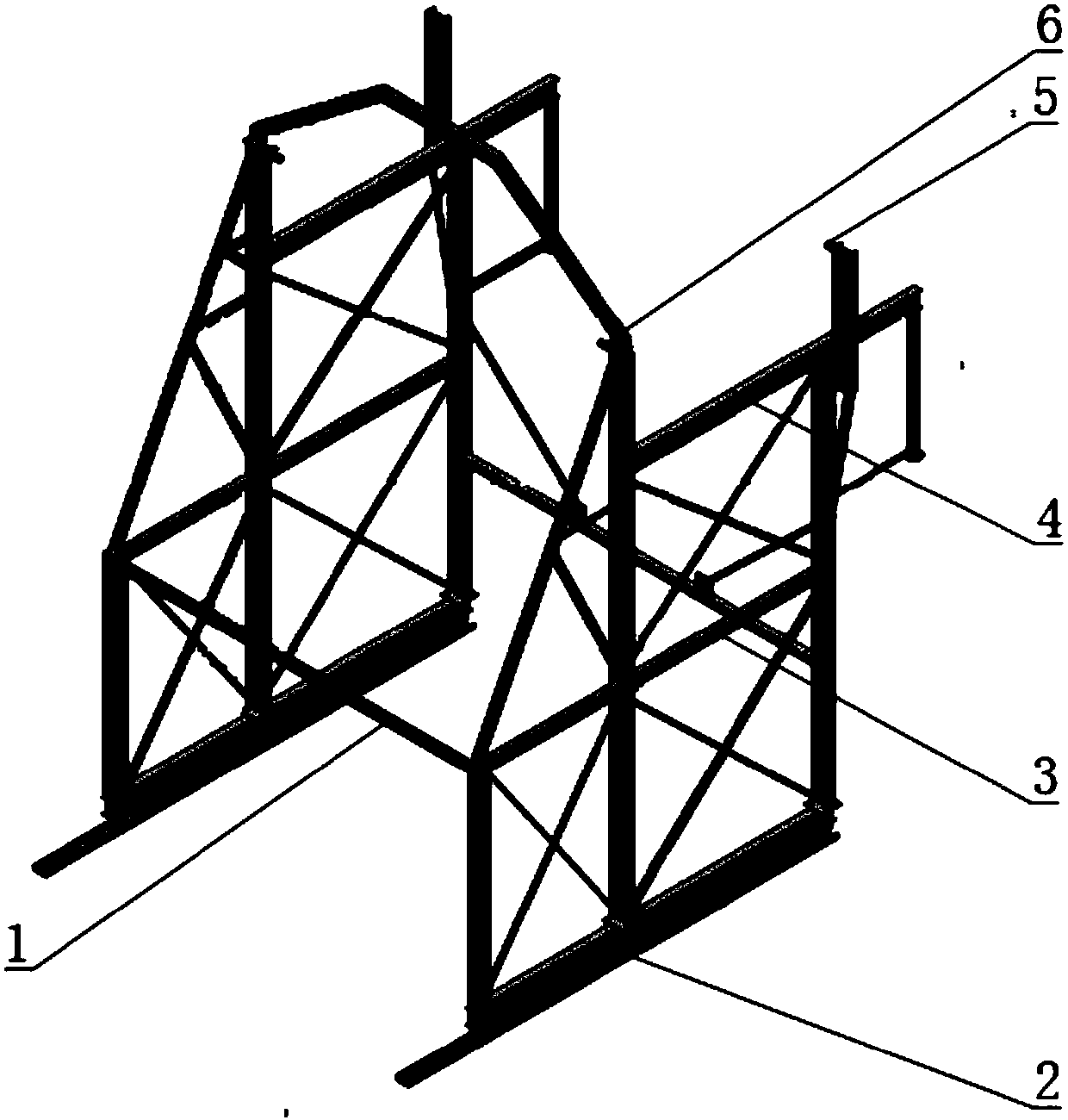

[0021] Such as Figure 1-3 As shown, an integrated device for oil tank transportation and installation includes a horizontal moving device 2, a door frame 3 and a sliding device 4; the door frame 3 rolls along the horizontal moving device 2; the horizontal moving device 2 includes Centerline direction, two tracks matched with the width of the door frame 3 and a rolling device arranged on the door frame 3 that can roll along the tracks; the sliding device 4 includes two slide rails arranged on the top of the door frame 3 along the direction of the tracks and can Disassemble the two symmetrical shafts arranged in the oil tank circumferential direction; the two shafts are respectively matched with the two slide rails; the door frame 3 is provided with a lifting device, and the lifting device includes a front-end lifting device 6 corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com