Cardan joint floating butt joint structure

A universal joint and axial technology, applied in the direction of elastic couplings, mechanical equipment, couplings, etc., can solve the problems of non-floating in the angular direction, serious wear of the guide rod, and small floating amount, so as to increase the floating function, High docking success rate and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

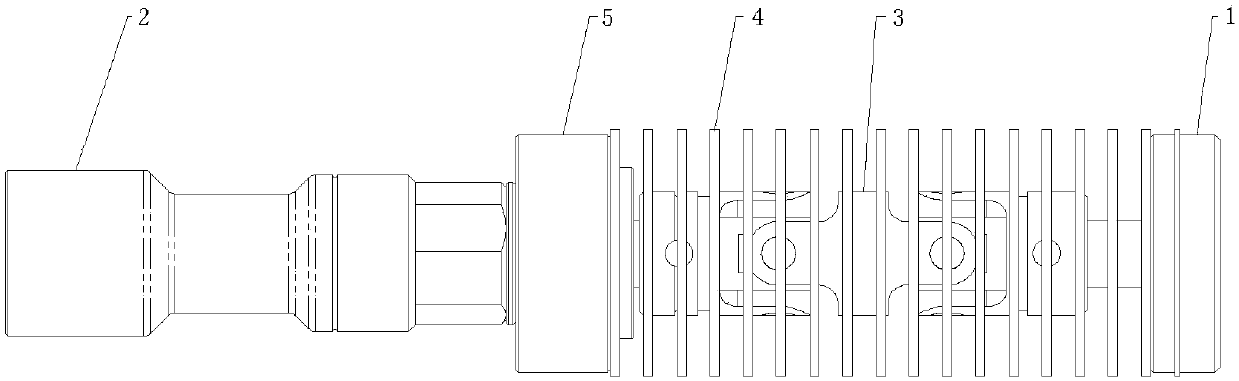

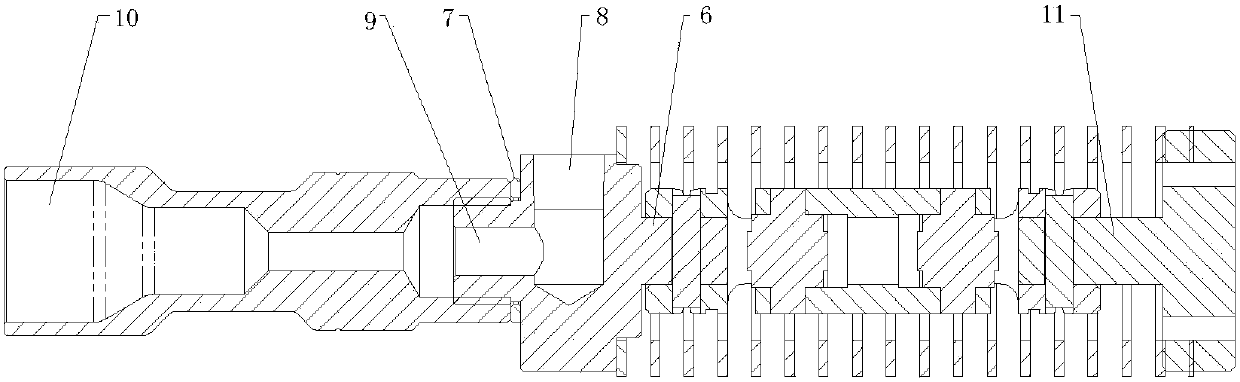

[0018] see Figure 1 to Figure 2 , the universal joint floating docking structure of this embodiment, the specific structure is set as:

[0019] Set the rear end of the push rod 1 driven by the power source, and the quick docking female head 2 coaxial with the push rod 1 is set at the front end of the push rod 1 for docking with the quick docking male head, and at the front end of the push rod 1 and the quick docking At least one universal joint 3 is arranged in series in the axial direction between the rear ends of the female connectors 2, and the outer side of the universal joint 3 is provided with a spring 4, and the power source pushes the push rod 1 to drive the quick docking female connector 2 forward and fast docking When the male head is docked, the universal joint 3 is pressed to float in the horizontal, vertical and angular directions to form a floating docking structure, and the spring 4 is used for automatic return after docking and withdrawal to form a locking str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com