Floating mechanism and battery replacing trolley with same

A floating mechanism and electric trolley technology, which is applied in the field of charging and swapping, can solve the problems that the surface of the battery swapping trolley is not parallel to the bottom of the vehicle body, the adjustment process is cumbersome, and the user experience is poor, so as to improve the experience, the adjustment process is simple, and the structure is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the floating mechanism proposed according to the present invention and the battery-swapping trolley including it and its Efficacy, detailed as follows.

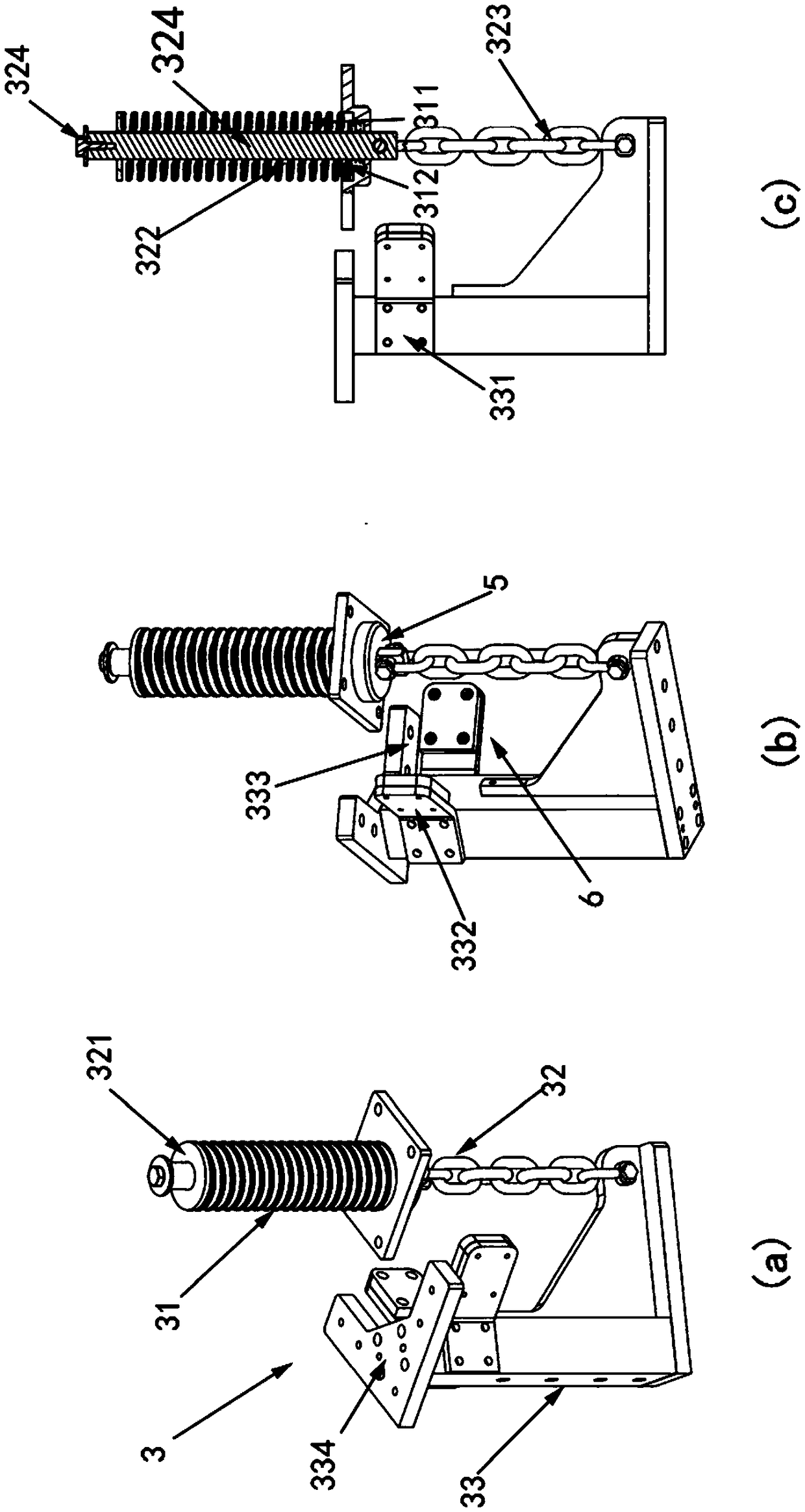

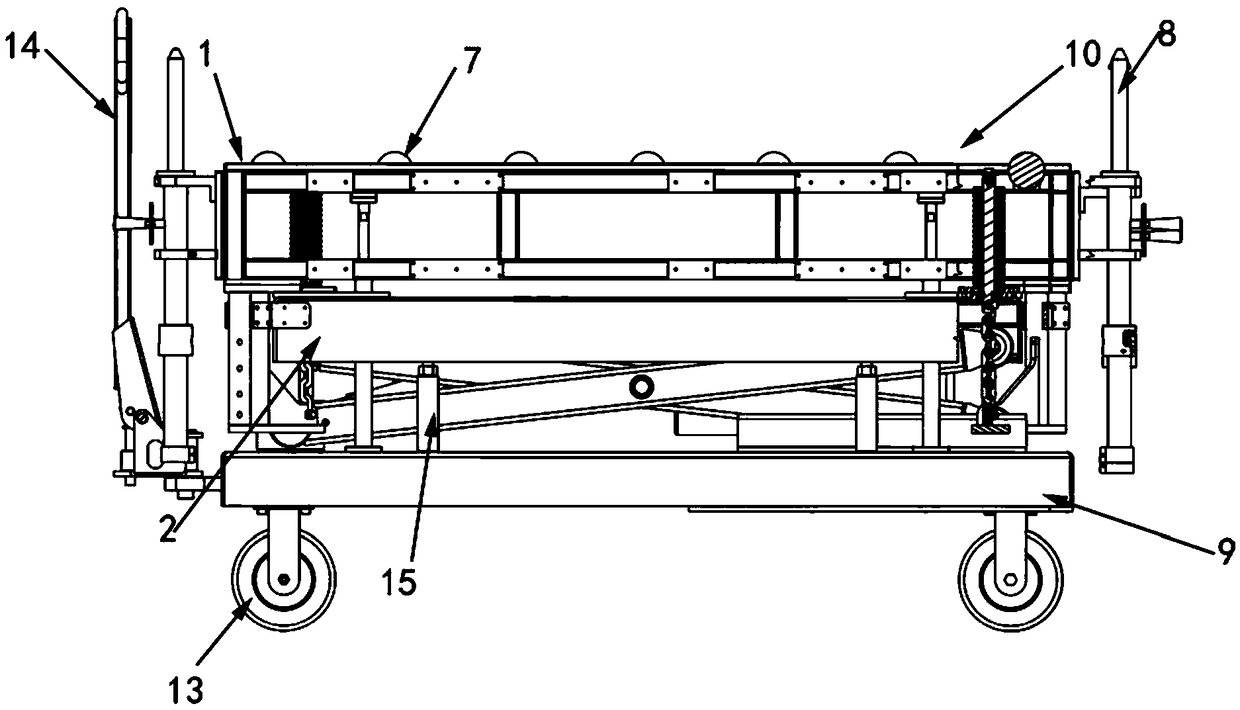

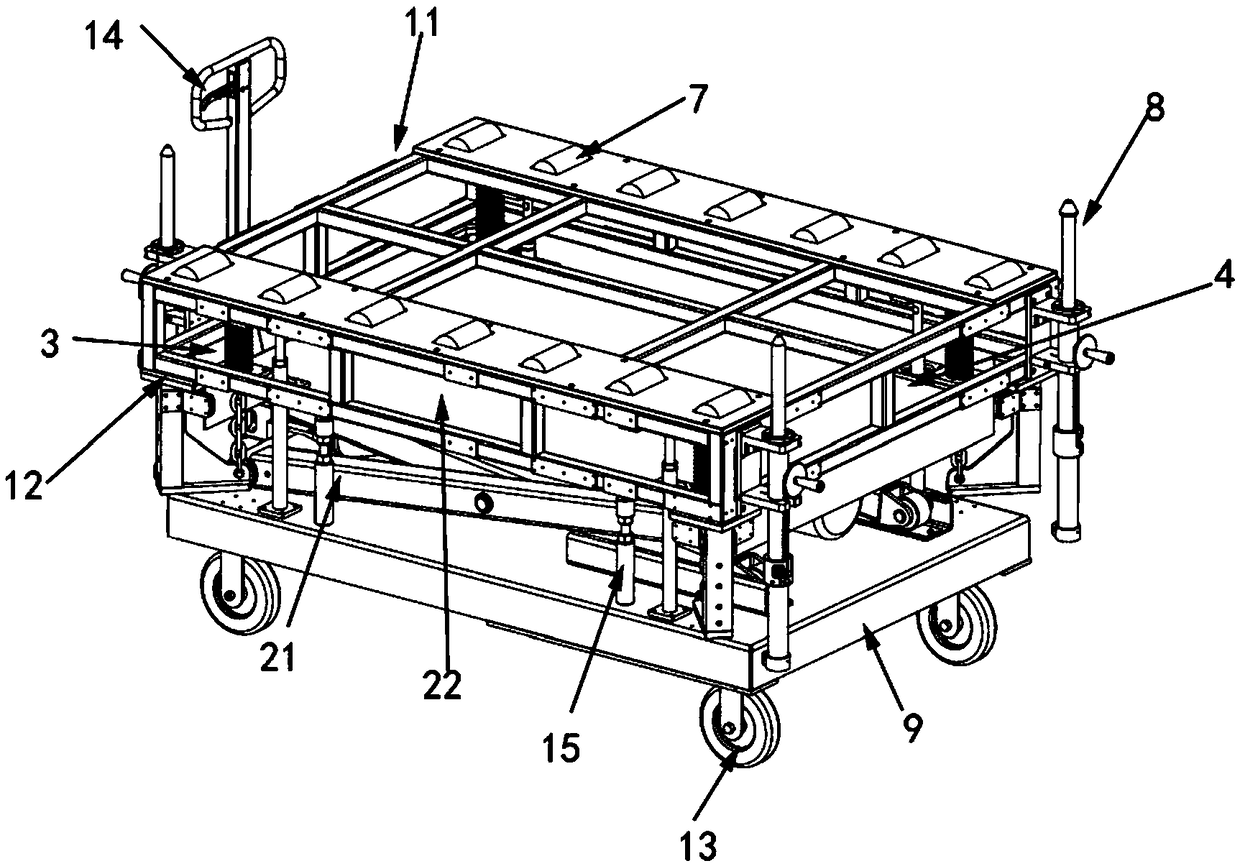

[0049] The embodiment of the present invention provides a floating mechanism, including a floating part 1, a fixed part 2 and a plurality of connecting parts 3, wherein the floating part 1 and the fixed part 2 are arranged face to face, and there is a The first floating gap 4, the floating part 1 is used to support the target object, the target object is the object to be aligned or positioned, for example, when the floating mechanism is applied to the power exchange equipment in the power exchange station, such as power exchange In the case of a trolley, the target object is a battery pack. Such as figure 1 (a), figure 1 (b), figure 1(c) shows the exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com