Plug connector shell, plug connector and connector assembly

A technology of plug connectors and plug housings, which is applied to parts, connections, electrical components, etc. of connection devices, and can solve the problem of sedimentation, corrosion of the locking structure of push-pull self-locking connectors, and failure to realize push-pull self-locking connectors The problem of normal separation or locking of the locking structure, to achieve the effect of preventing corrosion, ensuring normal separation or locking, and convenient and accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

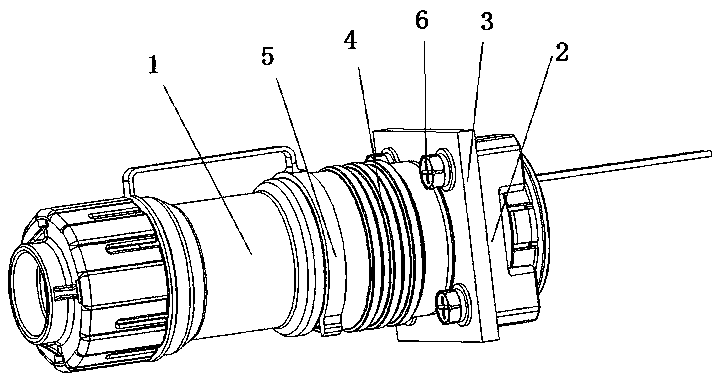

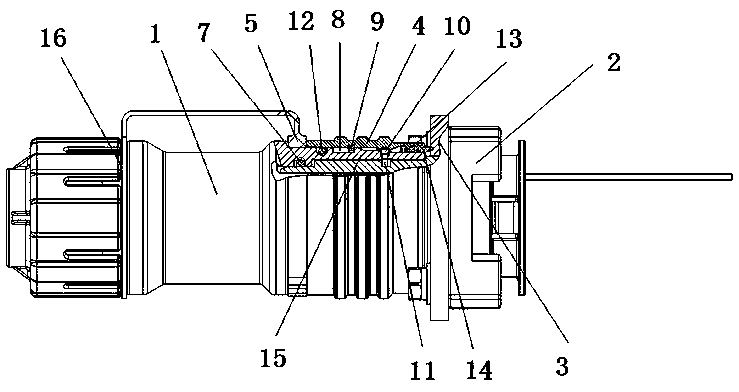

[0071] Attached below Figure 1 to Figure 2 The connector assembly of the present invention will be further described.

[0072] Such as figure 1 As shown, the connector assembly includes a plug connector 1 and a receptacle connector 2, the plug connector 1 and the receptacle connector 2 are mated, the housing of the receptacle connector 2 is provided with a fixed panel 3, and the fixed panel 3 is provided with Through holes for the screws 6 to pass through, the socket connector 2 is installed on the base body through the fixing panel 3 to realize the fixing of the socket connector 2 . The front end of the housing of the plug connector 1 is a plug-in section 15, and a locking sleeve 4 is sleeved on the plug-in section 15. The locking sleeve 4 can move axially relative to the plug-in section 15 to realize the connection between the plug connector 1 and the socket connector. 2 Locking after mating.

[0073] The housing of the plug connector 1 is provided with an axial limit st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com