Flexible force sensor calibration test platform and method

A test platform and force sensor technology, which is applied in the field of sensor calibration, can solve problems such as the inability to calibrate the influence of shear stress, and achieve the effect of eliminating shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

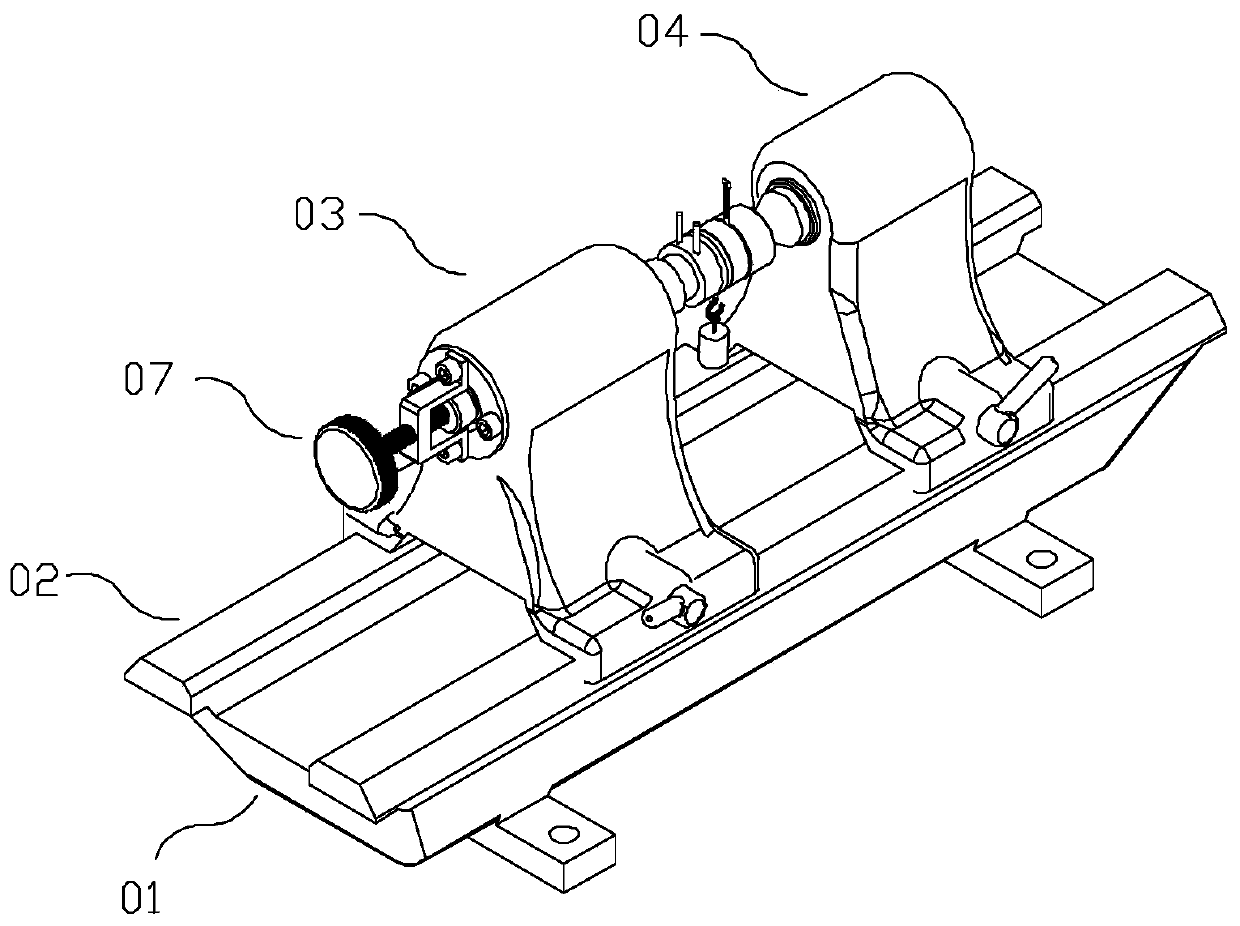

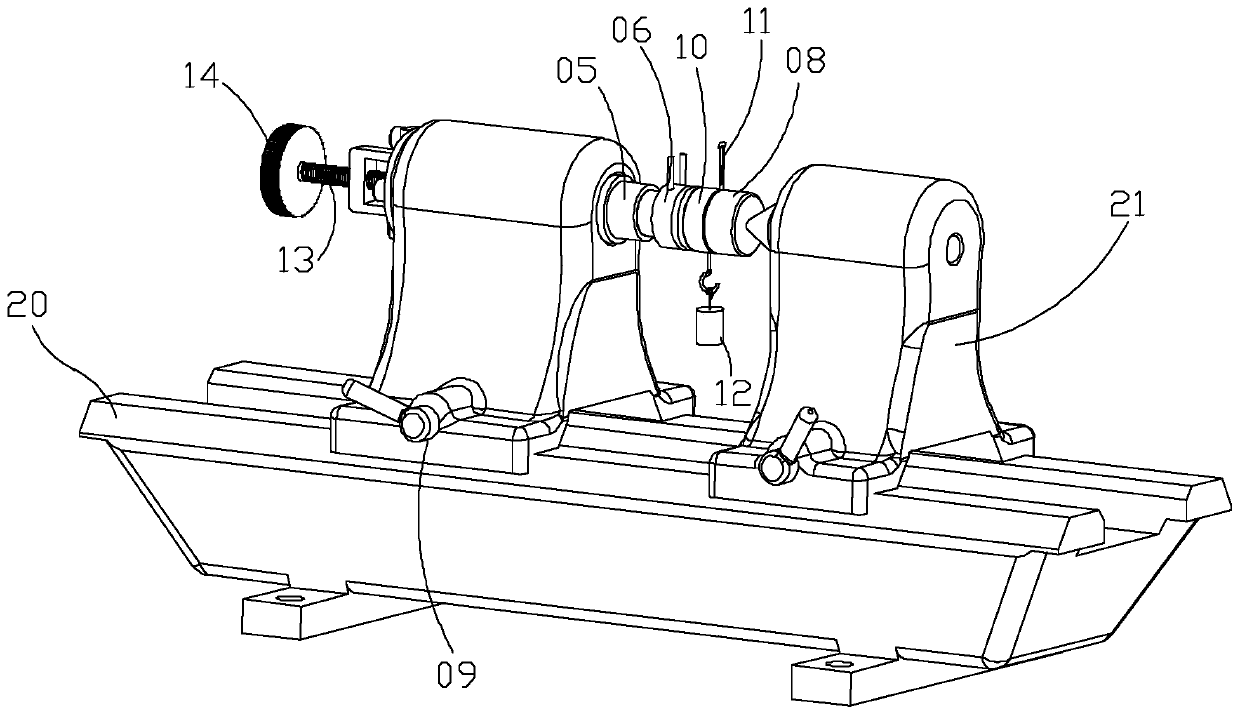

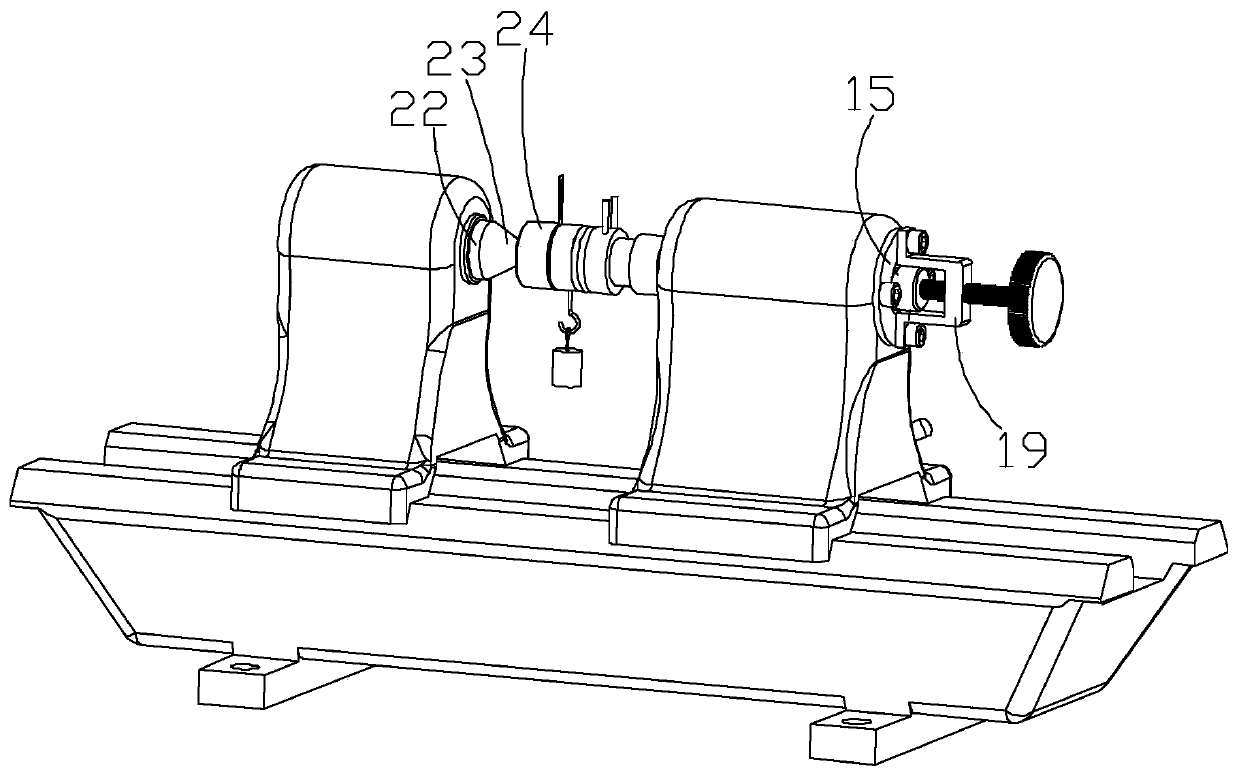

[0053] like Figure 1 to Figure 4 As shown, the flexible force sensor calibration test platform of this embodiment includes a platform-shaped base 01, the base 01 has a horizontal rail 02, a first sliding seat 03 and a second sliding seat 04, the first sliding seat 03 and the second sliding seat 04 The sliding seat 04 forms a horizontal sliding pair with the horizontal track 02 respectively; the first sliding seat 03 has a channel 16, and one end of the channel 16 is provided with a piston column 05, and the end of the piston column 05 protruding from the channel 16 is fixedly connected with a single-dimensional force sensor 06 , the force measuring direction of the single-dimensional force sensor 06 is the horizontal direction, the other end of the channel 16 is provided with an adjusting rod 07, and the channel 16 is provided with a transmission mechanism, and the adjusting rod 07 is connected to the piston rod 05 through the transmission mechanism; the second sliding seat 0...

Embodiment 2

[0062] The calibration method of this embodiment uses the flexible force sensor 11 of Embodiment 1 to calibrate the test platform, and the specific steps include:

[0063] The first step is to fix the first sliding seat 03 on the horizontal track 02 through the locking member 09, so that the single-dimensional force sensor 06 is in a fixed position; slide the second sliding seat 04 along the horizontal track 02 to the first sliding seat 03, and at the same time Place the movable pressing block 10 and the flexible force sensor 11 to be calibrated between the one-dimensional force sensor 06 and the fixed pressing block 08, the flexible force sensor 11 is located between the movable pressing block 10 and the fixed pressing block 08, and the movable pressing block 10 The hook is directly below the movable pressing block 10; when the single-dimensional force sensor 06 and the fixed pressing block 08 clamp the movable pressing block 10 and the flexible force sensor 11, and the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com