Waterproof chassis assembly

A chassis and component technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve problems such as inventory management difficulties and increase design costs, meet assembly requirements, reduce repetitive designs, and facilitate inventory management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, specific embodiments of the present invention will be described in detail in conjunction with the accompanying drawings, but they are not intended to limit the present invention.

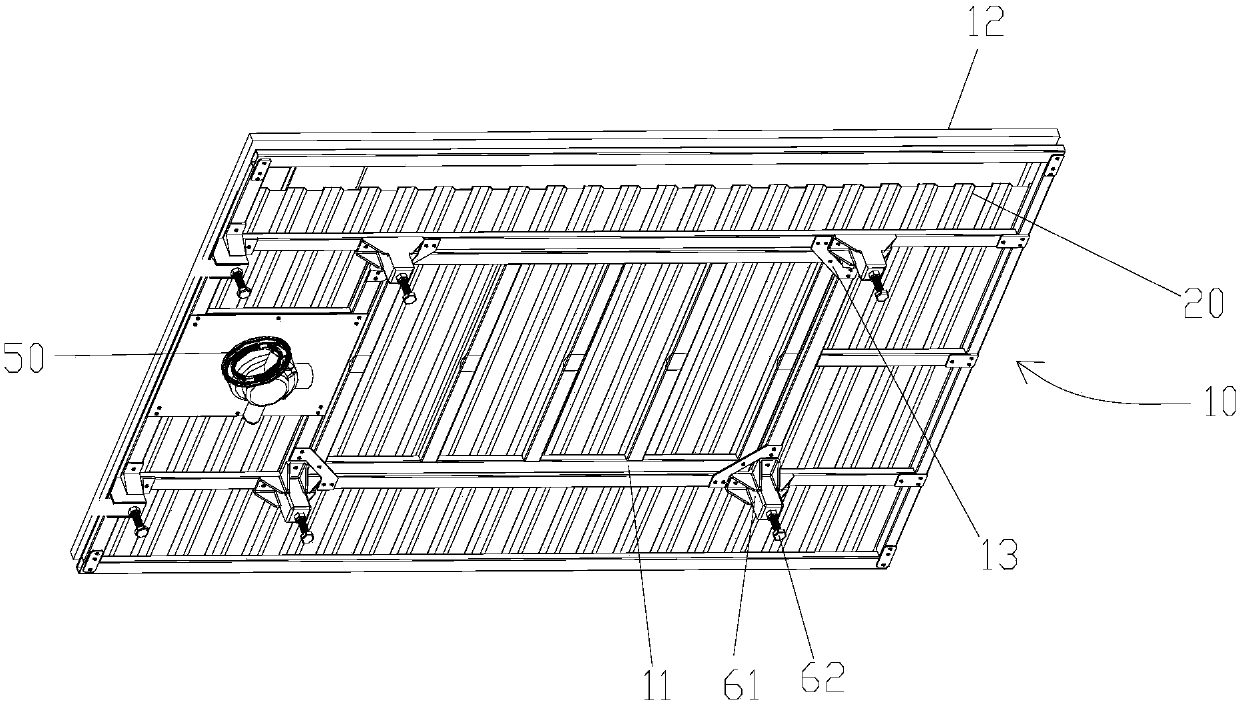

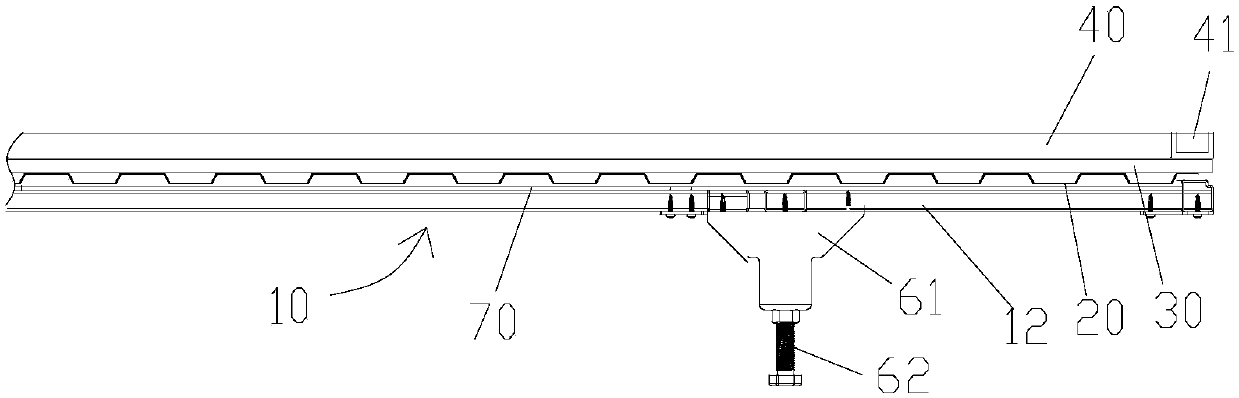

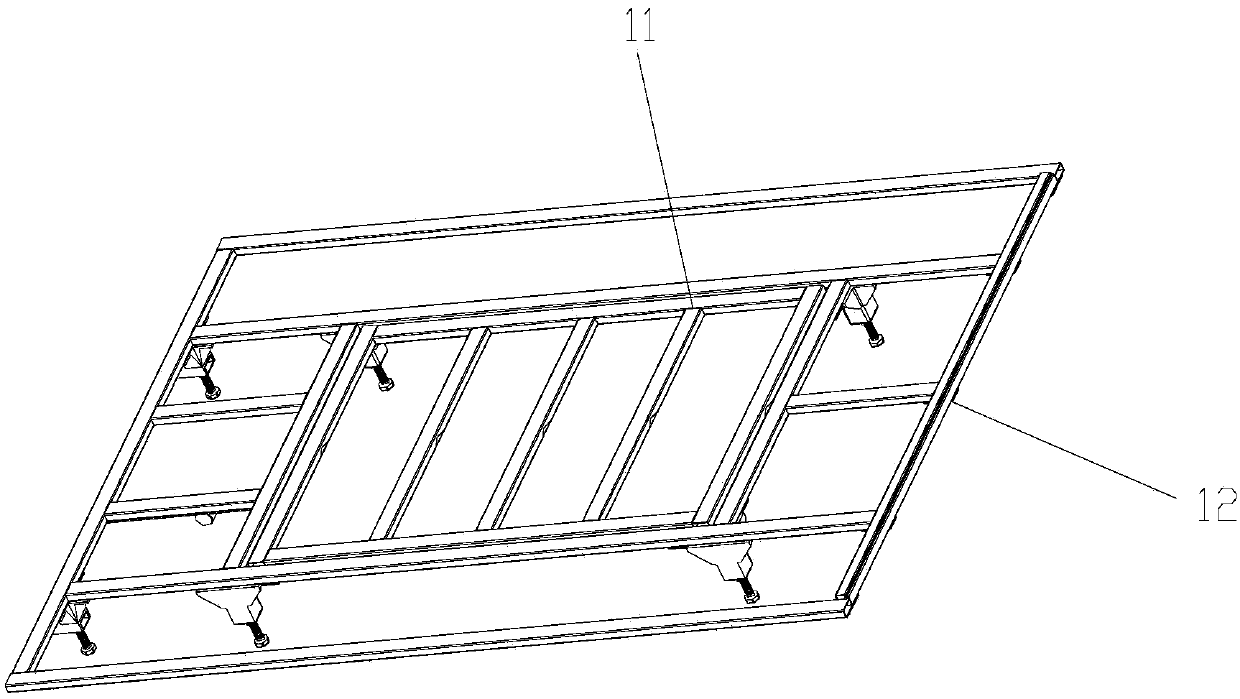

[0024] Such as Figures 1 to 4 As shown, the embodiment of the present invention provides a waterproof chassis assembly, which is used to be installed on the structural floor of the bathroom in the form of prefabricated decoration. Each part of the waterproof chassis assembly is prefabricated, specifically, the waterproof chassis assembly includes a prefabricated chassis body 40 and a support assembly 10, the support assembly 10 is used to erect on the structure ground, and the prefabricated chassis body 40 is used to lay on the support Component 10 on. The key of the present invention is: the support assembly 10 comprises a prefabricated skeleton body 11 and a plurality of prefabricated skeleton mounting bodies 12 gradually increasing in size (only one skeleton mounting body 12 is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com