Lock body structure capable of stopping lock core twisted

A lock body and lock cylinder technology, which is applied in building locks, building structures, buildings, etc., can solve problems such as keyhole exposure, lock cylinder anti-twisting function, and restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

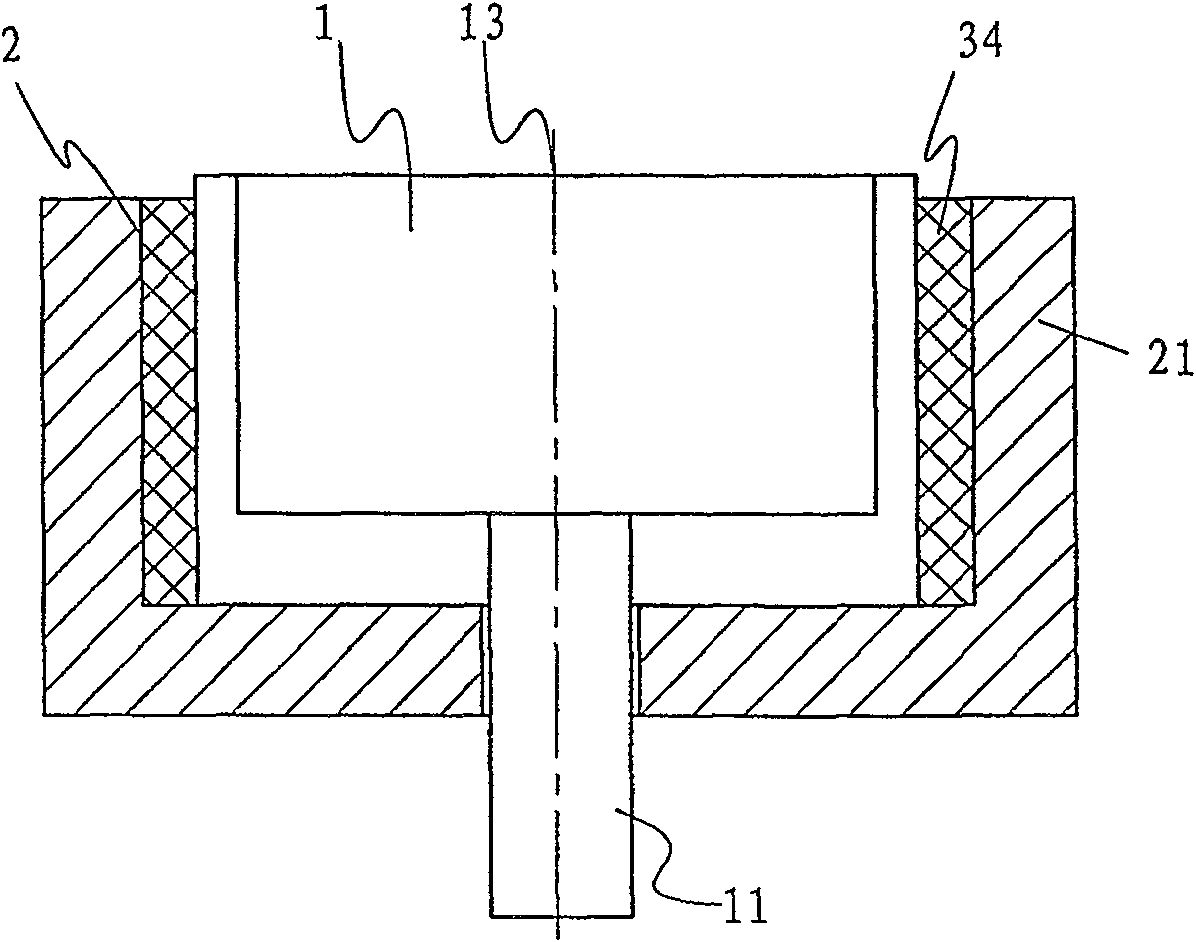

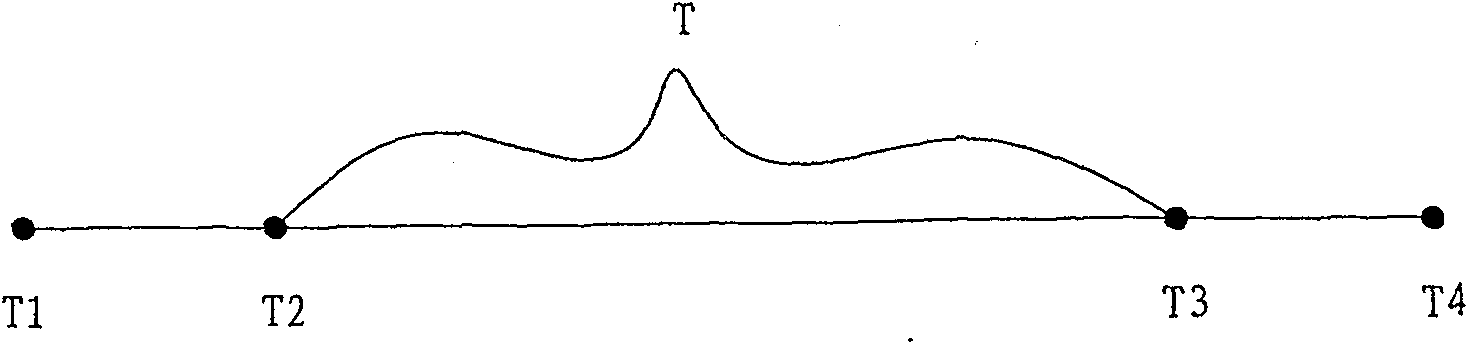

[0053] Such as figure 2 As shown, the lock body structure of the present invention includes a top lock head 1 (pushlock, which can be called a push lock in Chinese) arranged in the installation hole 2. The installation hole 2 is surrounded by side walls 21, and the lock bolt 11 is inserted and locked. Lock in the lock hole (not shown in the figure) of the object, and the top lock head 1 and the installation hole 2 are falsely fixed. Between the force and the torsional force that the lock cylinder is twisted. see Figure 2A , the torsional force of normally opening the lock body by the key is within the normal torsional force range T1-T2, and the lock core of the lock body 1 also has a twist-resistant or twist-resistant range T3-T4, the false fixation of the present invention is You can choose between these two ranges. Optimally, the strength T of the pseudo-fixation is between the maximum torsion force T2 that can be generated by the key to open the lock body normally and ...

Embodiment 2

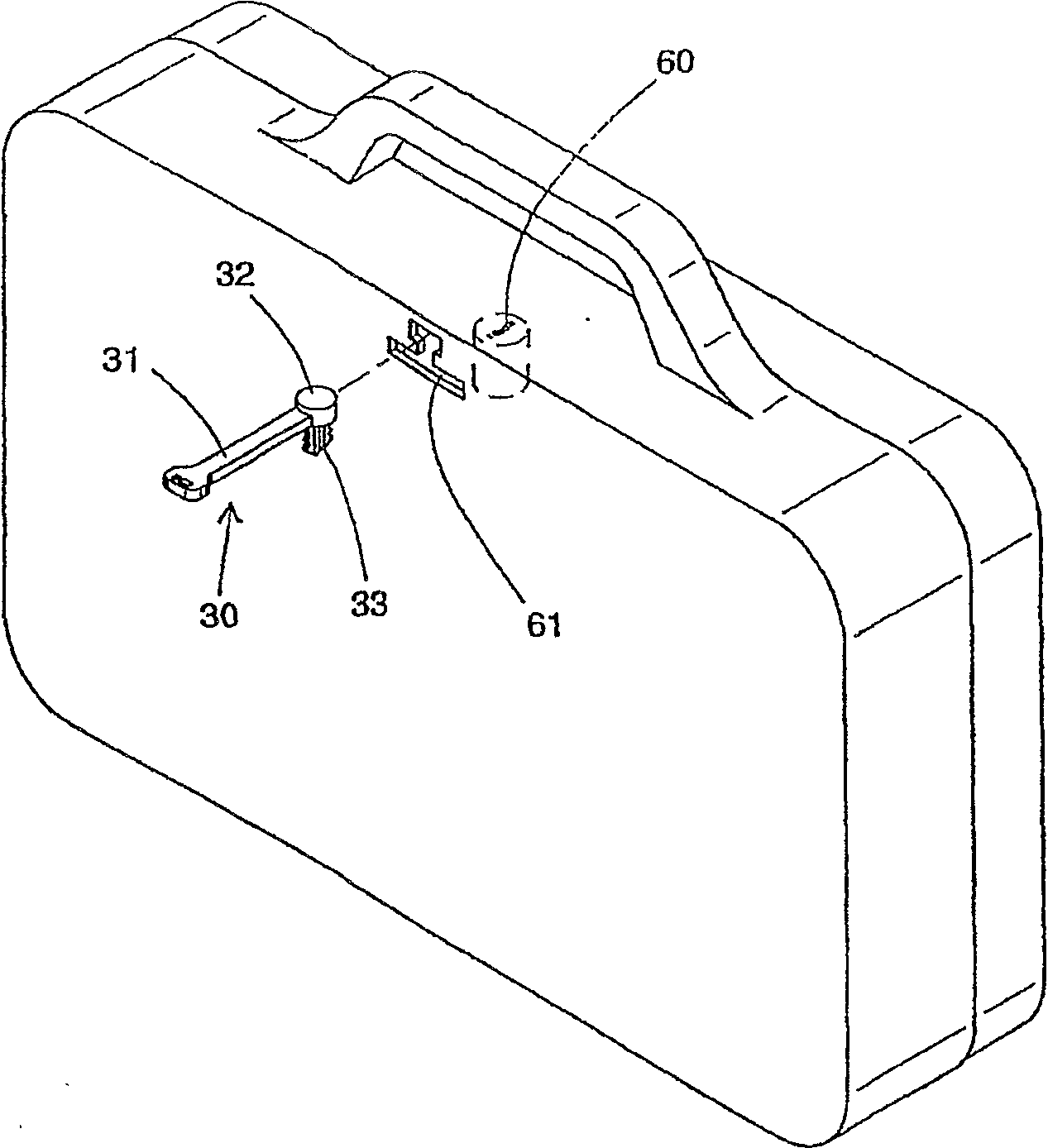

[0059] see Figure 6, this embodiment is on the basis of embodiment 1, the installation hole is located in an additional lock body 4, the additional lock body 4 is provided with a through hole 43 for the deadbolt 11 to enter and exit and an opening 42 for the key to insert, the top The lock head 1 is arranged in the installation hole 41 of the additional lock body 4, and a pseudo-fixation is achieved between the installation hole 41 and the top lock head 1. In the figure, a circular tube-shaped step (or a rectangular step or an inner clip is used) The formed step) 40 realizes the axial tightening connection, of course, the elastic telescopic column pin 38 can also be used to realize false fixation. The additional lock body 4 can be made of a thin plate with a strip-shaped installation hole, or made of a leather sleeve, and its material can be selected from metal, high molecular polymer, wood or tempered glass, etc. The lock body can better protect the lock cylinder in it. The...

Embodiment 3

[0071] see Figure 11 , its principle and effect are exactly the same as those in Embodiment 2, and will not be repeated. The improvement is that an electronic alarm device 7 is further installed in the additional lock body 4 , and its switch 71 is connected by a wire 72 . The power switch 71 of the electronic alarm device 7 is similar to a bimetallic strip, and is triggered by the position movement of the deadbolt 11, further increasing the alarm prompt function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com