An aerodynamically optimized fuel-electric hybrid multi-rotor aircraft

A multi-rotor aircraft and rotor technology, applied in aircraft, rotorcraft, motor vehicles and other directions, can solve problems such as unfavorable improvement of endurance time and cruising speed, limited lift, slow blade end linear speed, etc., to improve the overall endurance time and The effect of cruising speed, increasing mount capacity, and increasing battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

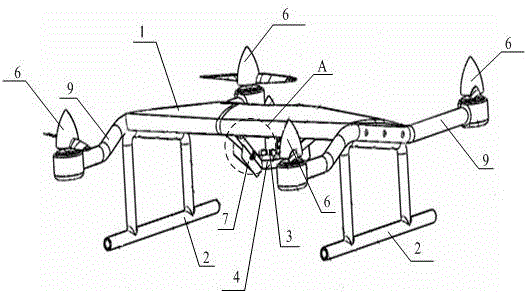

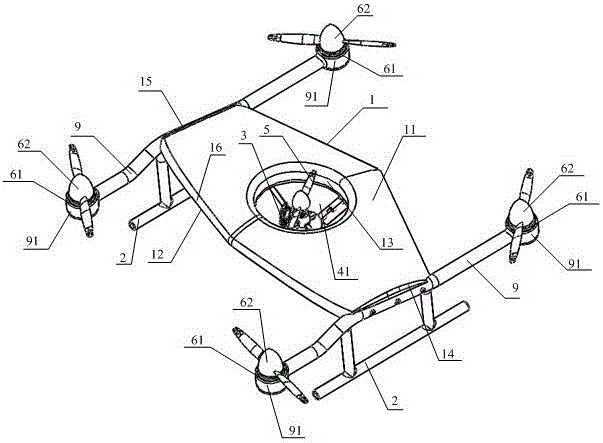

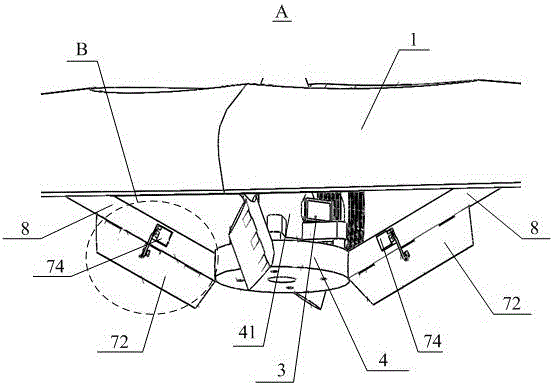

[0045] like Figure 1 to Figure 5 As shown, in the embodiment of the present invention, an aerodynamically optimized oil-electric hybrid multi-rotor aircraft is proposed. The multi-rotor aircraft includes:

[0046] A fuselage 1, the fuselage 1 includes an upper surface 11, a lower surface 12, and a first cavity 13 passing through the upper surface 11 and the lower surface 12; wherein, the fuselage 1 is made of carbon fiber material;

[0047] At least one landing gear 2, the landing gear 2 is fixed to the lower surface 12 of the fuselage 1;

[0048] a fuel engine 3;

[0049] A semi-enclosed installation platform 4 for installing the fuel engine 3, the installation platform 4 is fixed to the lower surface 12 of the fuselage 1, and it forms a second opening facing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com