Multi-functional clamp of underwater electric discharging machining electrode

A multi-functional, EDM technology, applied in the field of underwater EDM, can solve the problems of inconvenient operation, increased design difficulty, and increased development cost design difficulty, etc., to achieve the effect of reducing repeated design, reducing design cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

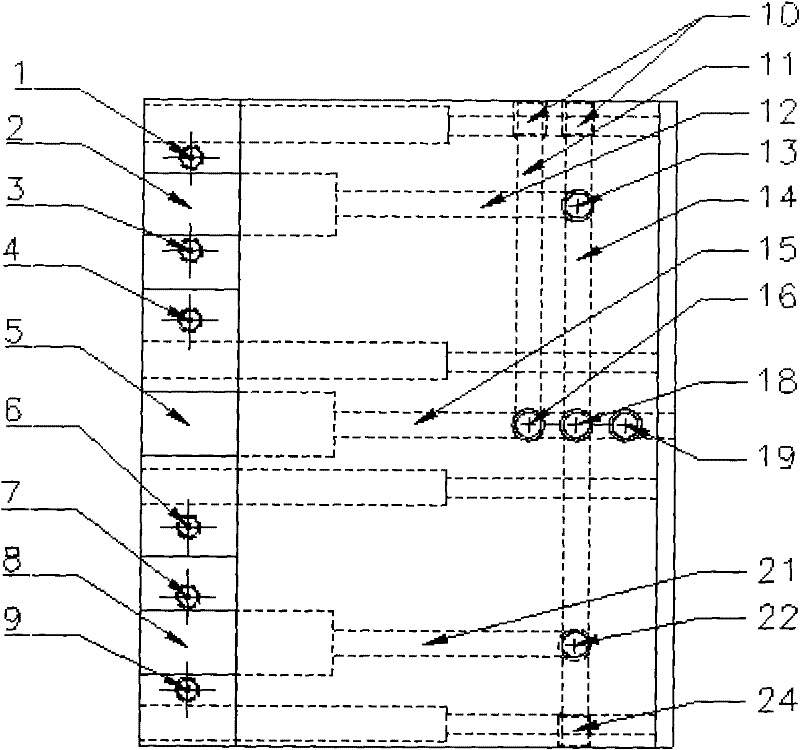

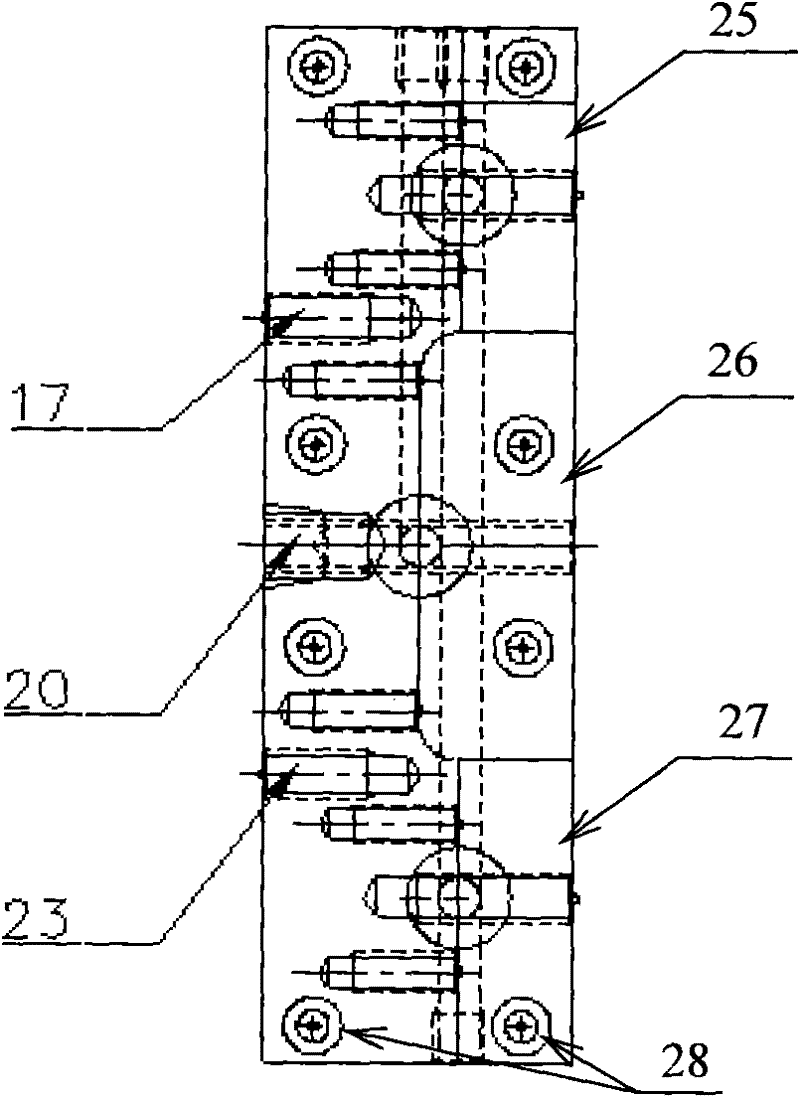

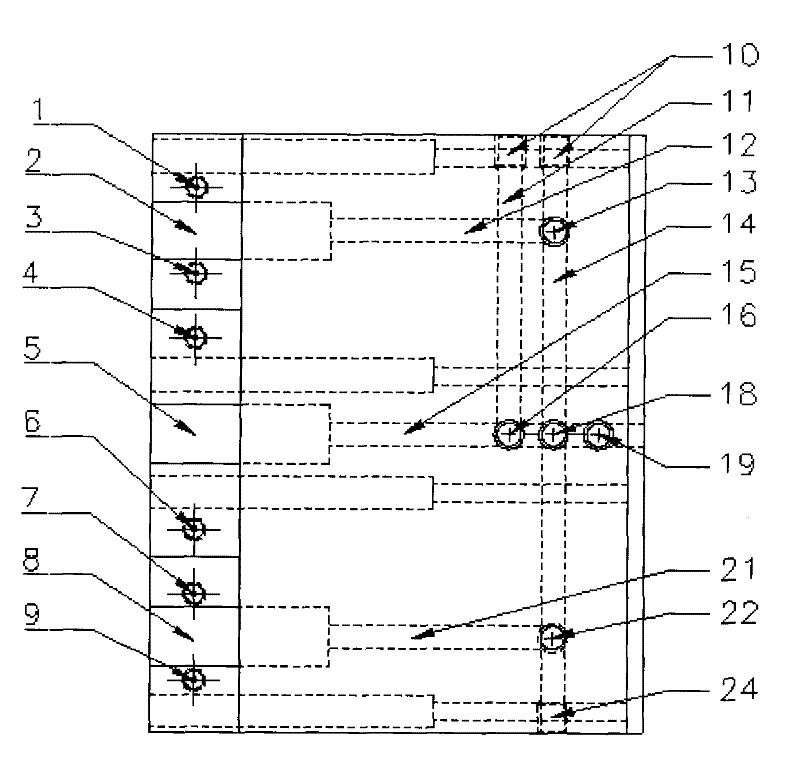

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 1 , figure 2 As shown, the underwater electric discharge machining electrode multifunctional fixture provided by the present invention is installed on a moving part, and the multifunctional fixture moves with the movement of the moving part. The multi-function fixture is made of conductive materials such as aluminum or stainless steel. The clamp has three cutting electrode installation and positioning holes 2, 5, 8, and the clamping of each electrode is realized by the electrode positioning and holding fixture 25, 26, 27 arranged on the electrode position. The round holes allow for secure positioning of the electrode on the fixture. The electrode positioning and holding fixture is provided with cutting electrode clamping bolts 1, 3, 4, 6, 7, 9. For example, the electrode positioning and holding fixture 25 can be controlled by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com