Production method of 3G communication signal converter shell

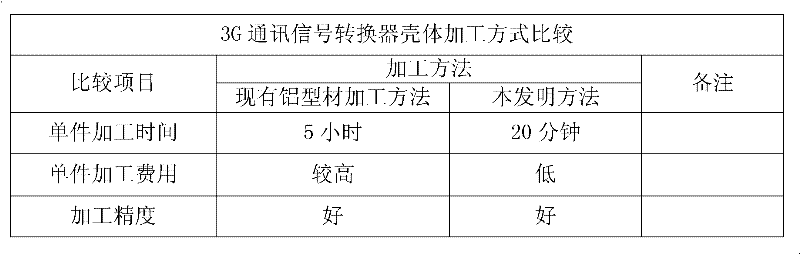

A communication signal and converter technology, applied in the direction of electrical components, selection devices, etc., to achieve good sealing, ensure size assembly, and overcome the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] At room temperature of 20 °C, the bottom case and the lid were die-cast using Al-Si alloy, and then the bottom case and the lid were machined, respectively.

[0012] The vertical high pressure casting is used for die casting, the casting pressure of the die casting machine is set to 12Mpa, the mold temperature is set to 210°C, and the temperature of the casting liquid (melt) is set to 650°C. The Al-Si alloy is put into the machine, and the injection speed used is 0.5-0.7m / s, and the casting liquid is injected into the cavity of the mold.

[0013] When the amount of casting solution injected into the cavity reaches 55% (volume ratio) of the total casting solution, the flow rate of the casting solution injected into the cavity is increased to 1.0-1.2m / s. The total amount of casting liquid refers to the amount of casting liquid required for die casting a part (including sprue, sprue, overflow well and other sprue systems).

[0014] When the casting liquid fills the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com