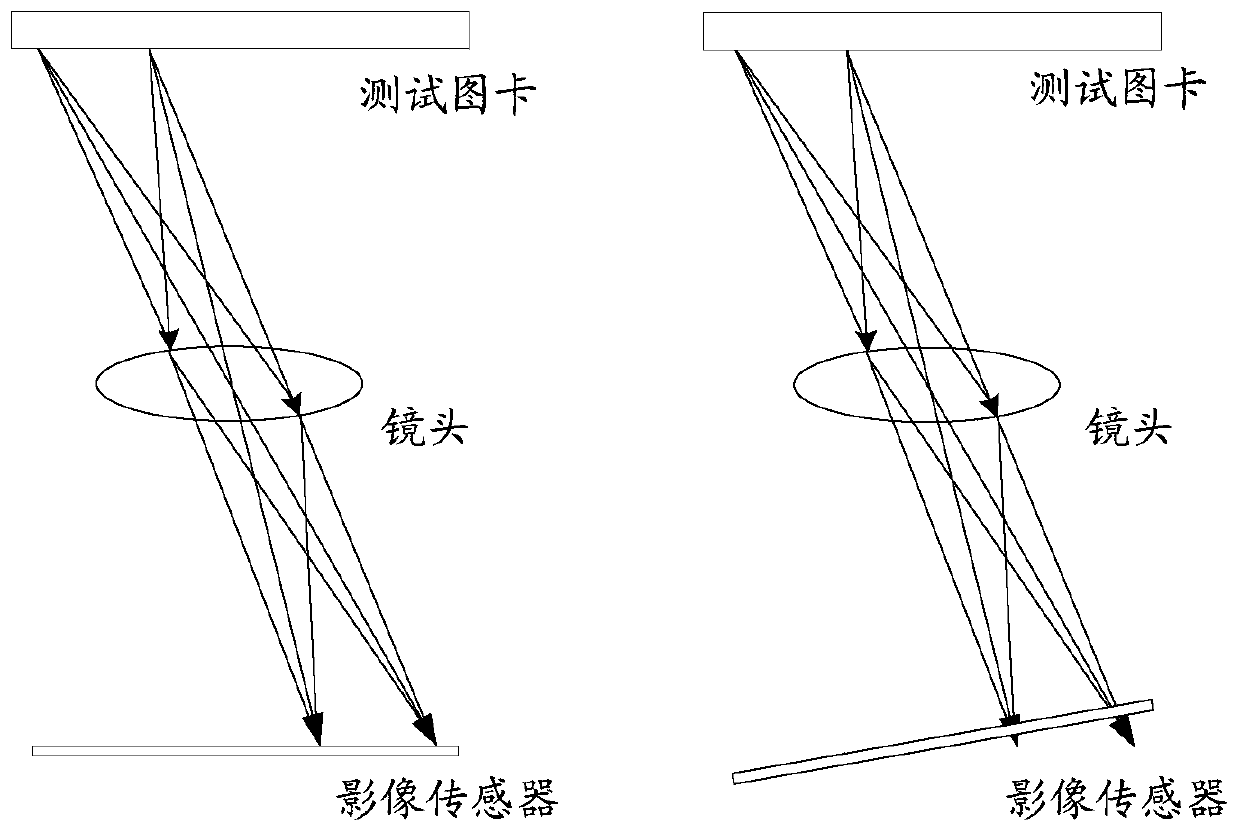

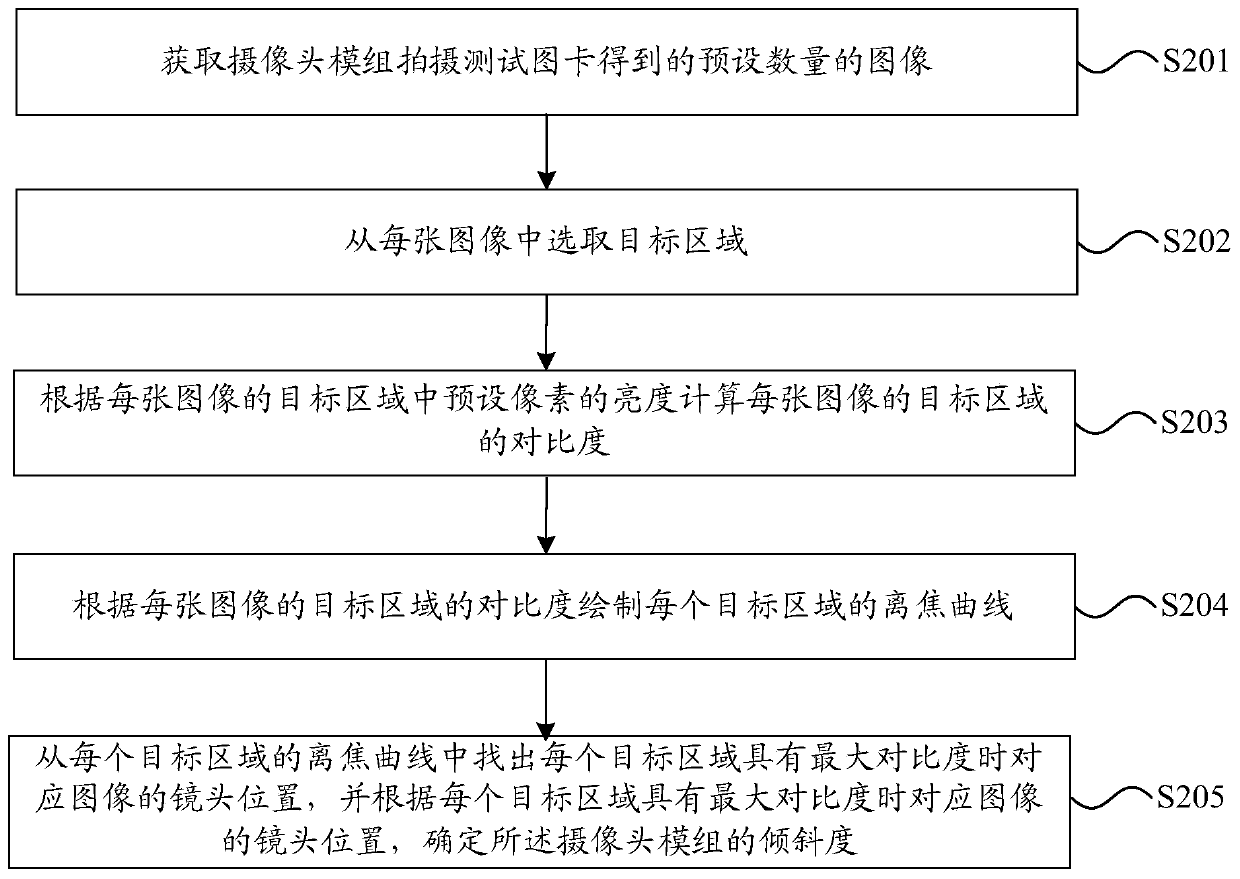

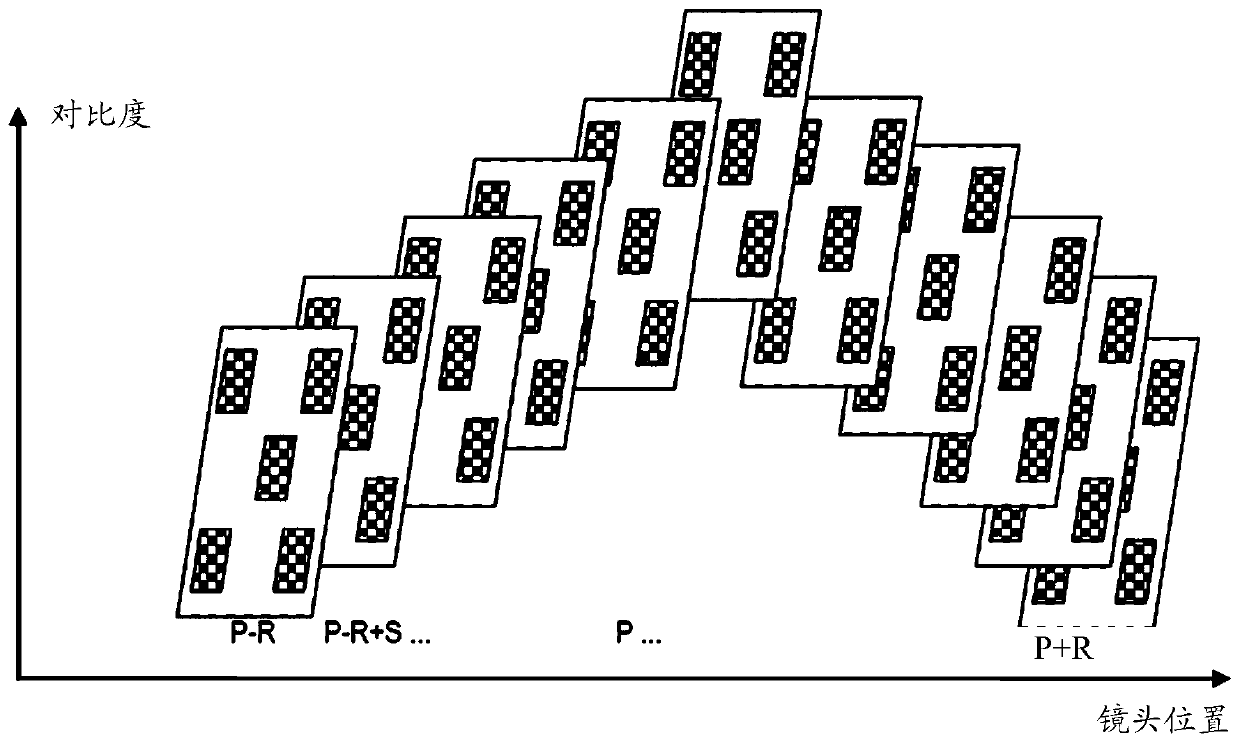

Camera module tilt test method and device

A technology of camera module and test method, which is applied in image communication, television, electrical components, etc., can solve the problems of low test accuracy, limited application scenarios, recognition failure or analysis error, etc., to improve test accuracy and stability, Wide range of test scenarios, avoiding the effect of errors or test failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Referring to the drawings, wherein the same reference numerals represent the same components, the principles of the present application are exemplified by being implemented in a suitable computing environment. The following description is based on illustrated specific embodiments of the present application, which should not be construed as limiting other specific embodiments of the present application that are not described in detail here.

[0031] In the following description, specific embodiments of the present application will be described with reference to steps and symbols executed by one or more computers, unless otherwise stated. Accordingly, these steps and operations will several times be referred to as being computer-implemented, which herein refers to operations by a computer processing unit of electronic signals representing data in a structured form. This operation transforms the data or maintains it at a location in the computer's memory system that can re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com