Drawing and grasping machine with distinguishing function and for production line

A production line and functional technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of high cost and reduced production speed, and achieve the effect of strong practicability, simple mechanical linkage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

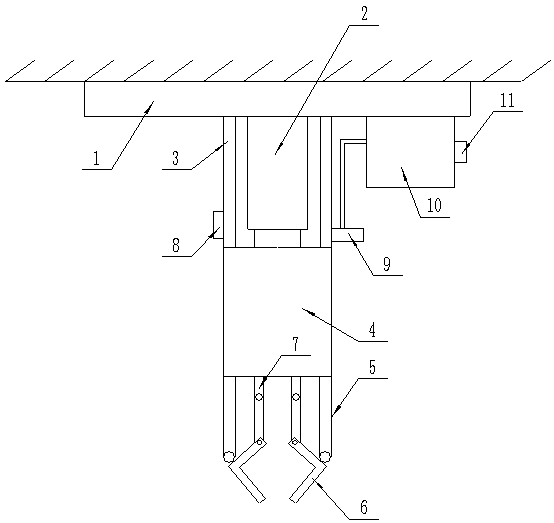

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, a grabbing machine with a distinguishing function used in a production line includes a base (1), a linear cylinder (2) is installed on the outer and lower surface of the base (1), and the outer and lower surface of the base (1) is A bracket (3) is installed on both sides of the linear cylinder (2), a scanner (9) is installed on the bracket (3), a hollow cylinder (4) is installed on the bracket (3), and the hollow The upper end of the cylinder (4) is equipped with a rectangular plate (5) at the two phase limit points, and the other end of the rectangular plate (5) is connected with an L-shaped gripper (6), and the linear cylinder (2) is telescopic Limiting plates (7) are installed at the opposite object limit points on the circumferential surface of the ends, and the other ends of the limiting plates (7) are respectively connected to the pin shafts at one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com