Printing printer with table board capable of being replaced and convenient-to-replace table board

A portable, platen technology, applied in typewriters, printing devices, printing, etc., can solve the problems of time-consuming clamping work, affecting printing work efficiency, not easy or impossible to replace, etc., to achieve easy replacement and installation, saving non-working Status, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

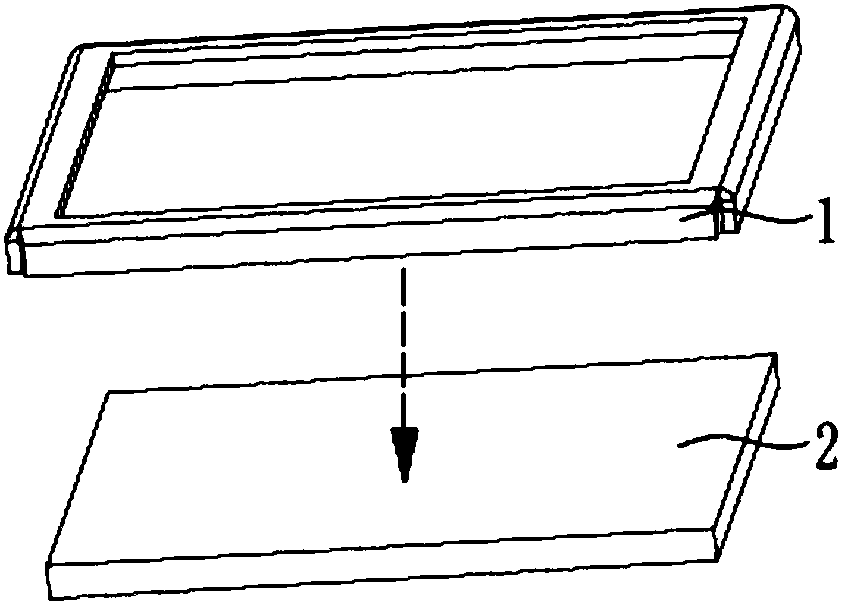

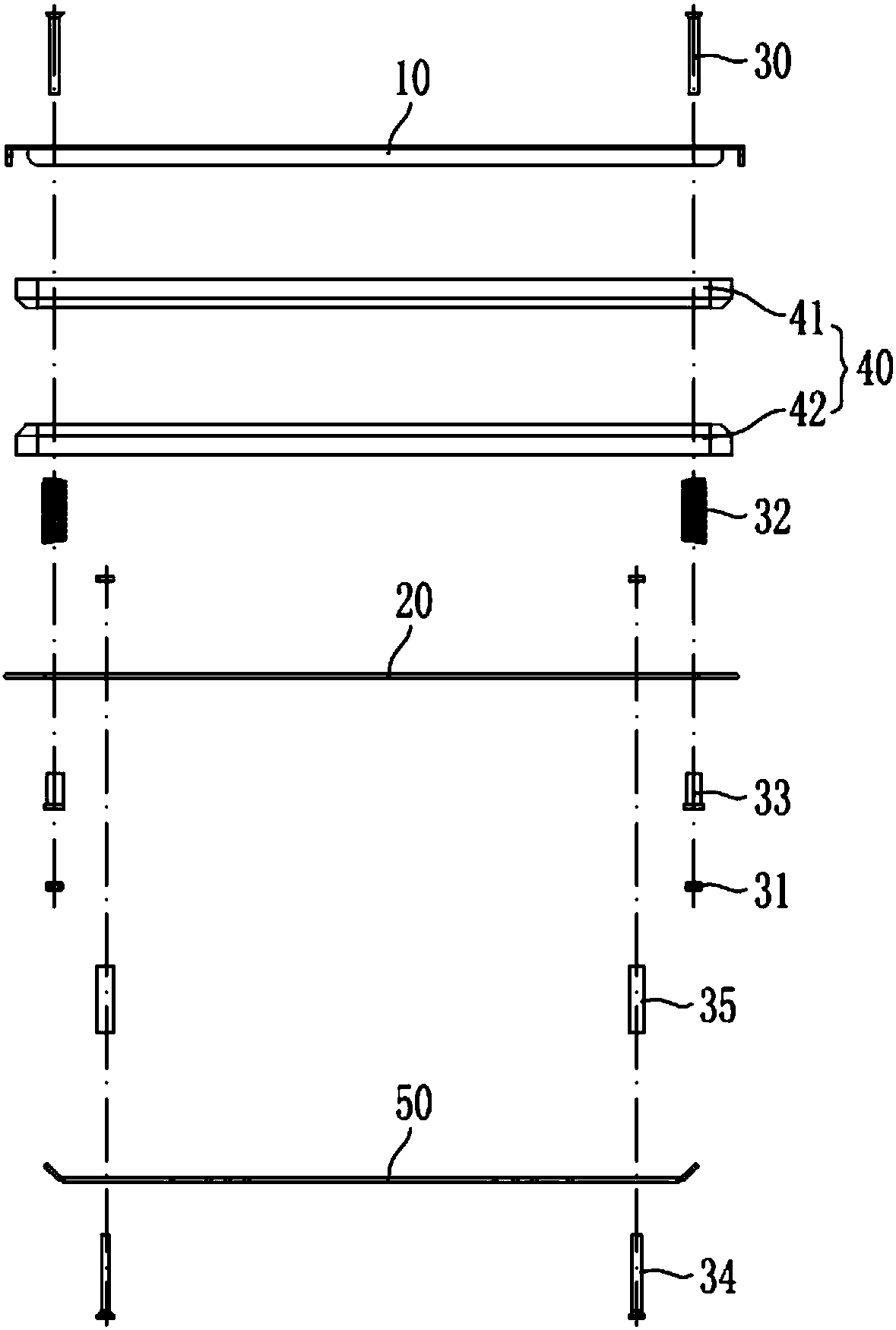

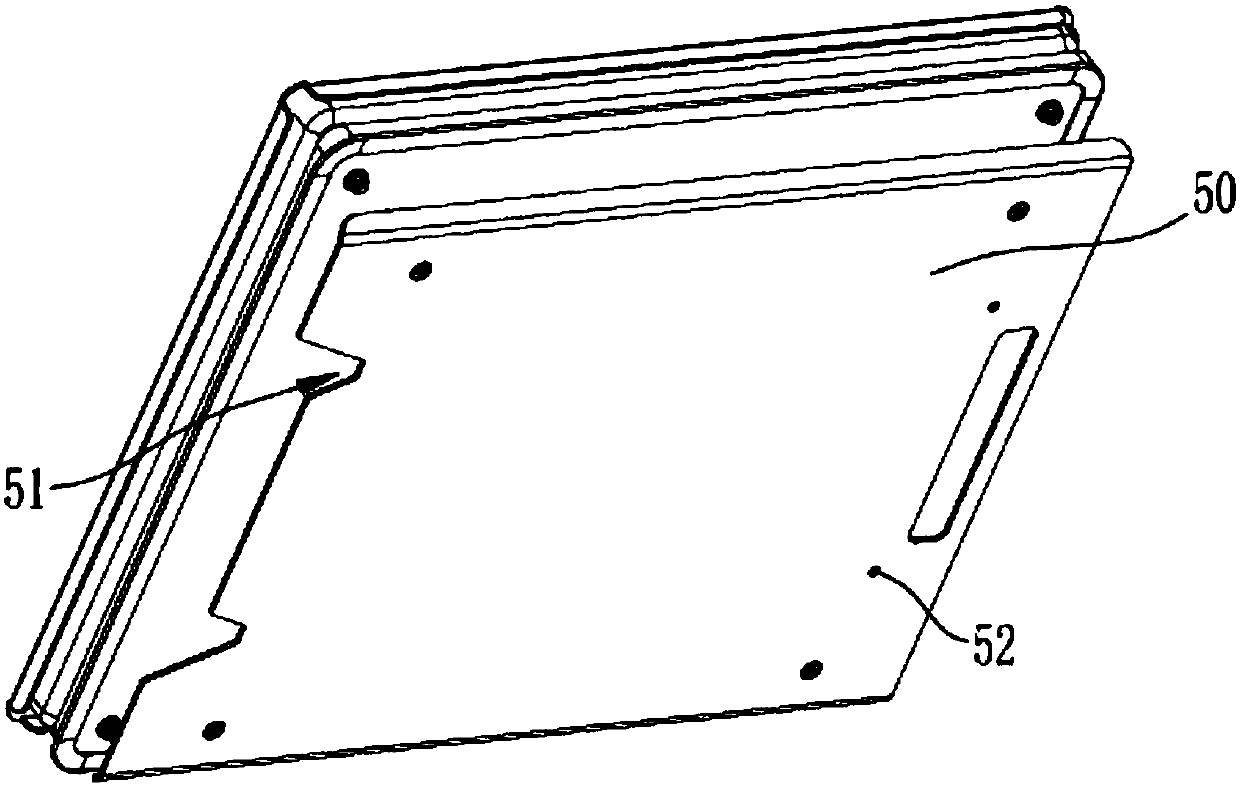

[0035] Such as Figure 2 to Figure 9 As shown, the convenient replacement of the platen in this embodiment includes:

[0036] The load-bearing top plate 10 has a load-bearing plane 11 for placing materials to be printed (such as cotton clothes), and the periphery of the load-bearing top plate 10 is bent downwards and chamfered to remove burrs at 360° (refer to Figure 6 with Figure 8 );

[0037] The middle support plate 20 is located at the lower part of the carrying top plate 10 and connected with the carrying top plate 10;

[0038] The elastic clamping assembly 40 is sandwiched between the loading top plate 10 and the intermediate support plate 20, and is used to clamp the material to be printed; the elastic clamping assembly 40 includes two oppositely arranged rubber elastic rings, namely The upper rubber elastic ring 41 and the lower rubber elastic ring 42 form a clamping gap by elastic force between the two rubber elastic rings; when clamping, at least part of the non...

Embodiment 2

[0043] The structural principles of this embodiment and Embodiment 1 are basically the same, and the similarities will not be repeated. The only difference is: refer to Figure 10 , Figure 11, in this embodiment, a support rod 70 is provided between the load-bearing top plate 10 and the positioning bottom plate 50, the support rod 70 passes through the middle support plate 20, and the two ends of the support rod 70 are connected to the load-bearing top plate 10 , The positioning base plate 50 is fixed by fastening screws 71; the middle part of the support rod 70 is provided with a limit step 72, and the support rod 70 is located on the rod body between the intermediate support plate 20 and the positioning base plate 50. Adjust the spring 73, so that the levelness of the bearing top plate 10 and the positioning bottom plate 50 is guaranteed by the support rod 70. When the clothes of different thicknesses are clamped, the adjustment spring 73 under the middle support plate 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com