Volute cleaning machine

A technology for washing machines and volutes, which is applied to dryers, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of uncleaning of volutes, generation of waste products, time-consuming and labor-intensive, etc., so as to improve the efficiency of cleaning and drying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

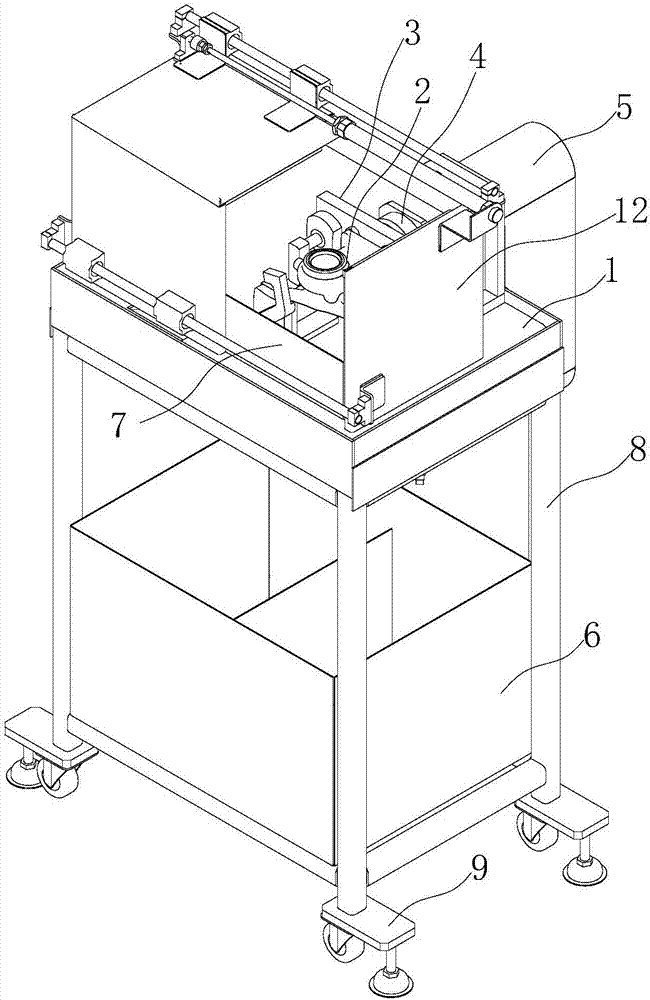

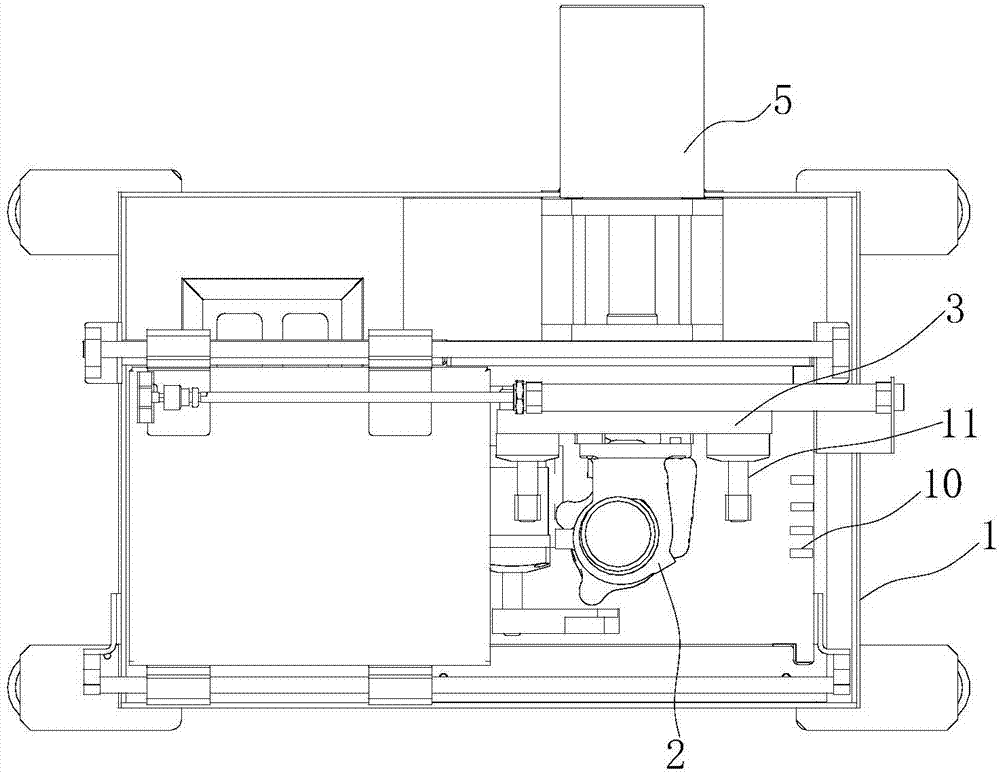

[0028] Such as figure 1 and figure 2 As shown, the present invention comprises a body, the body is provided with a workbench 1, and the workbench 1 is provided with:

[0029] A fixed plate 3 for carrying the volute 2;

[0030] A pressing mechanism for pressing and fixing the volute 2 on the fixed plate 3;

[0031] fixing the rotating shaft 4 passing through the fixing plate 3;

[0032] A drive mechanism 5 for driving the rotating shaft 4 to rotate;

[0033] A water spray mechanism for spraying washing water toward the volute 2.

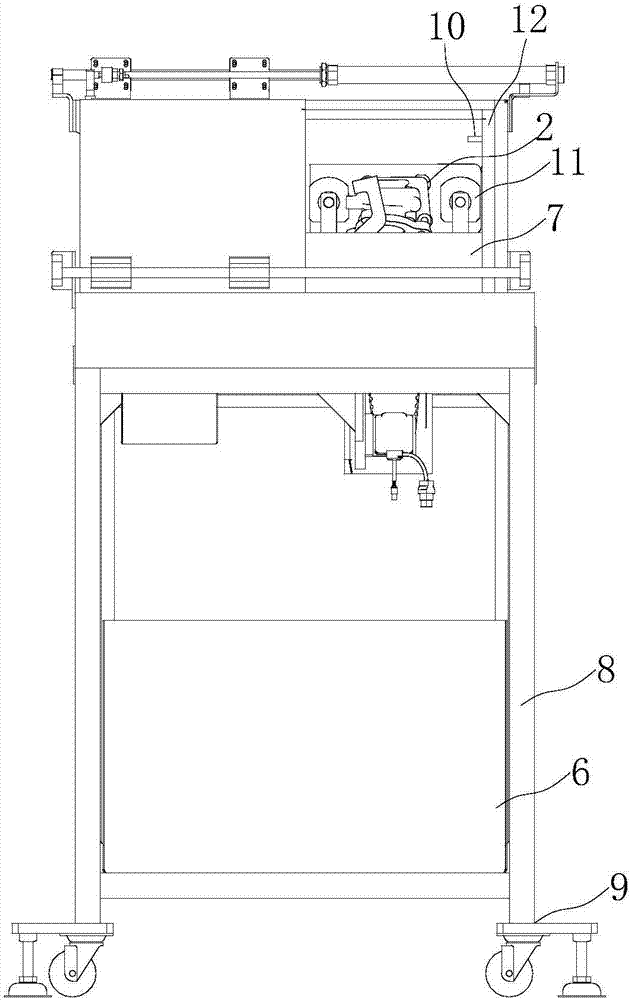

[0034] In order to facilitate recovery of the cleaning water of the volute 2, such as figure 1 and image 3 As shown, a recovery box 6 for recovering cleaning water is provided below the workbench 1 , and a drain for the cleaning water to flow into the recovery box 6 is provided on the workbench 1 . In order to prevent the cleaning water from flowing out, which is inconvenient to clean up, the workbench 1 is provided with a water baffle 7 whic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap