Diffuser used for centrifugal compressor and centrifugal compressor with diffuser

A centrifugal compressor and diffuser technology, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., and can solve problems such as vibration and compressor surge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

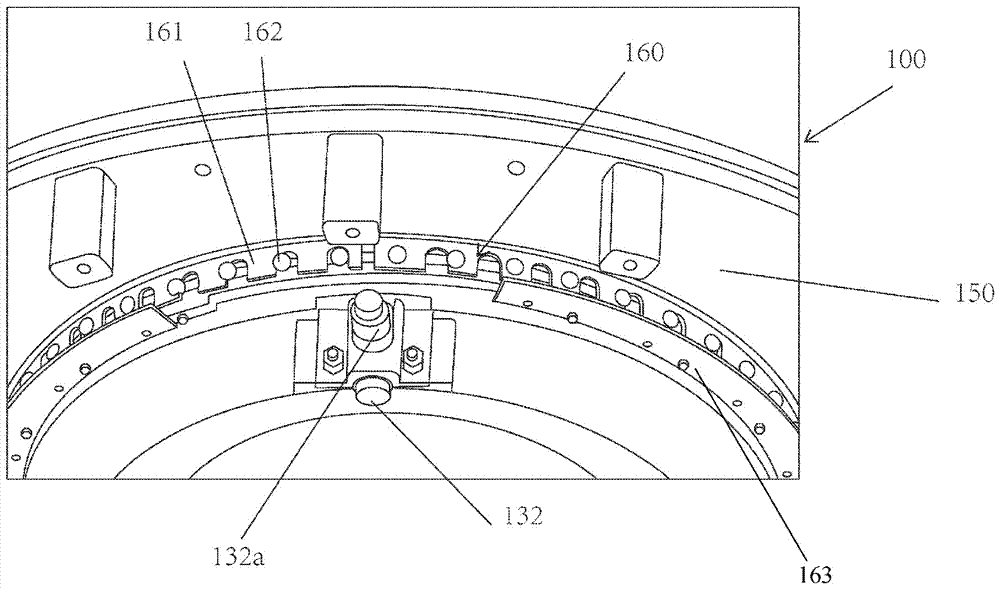

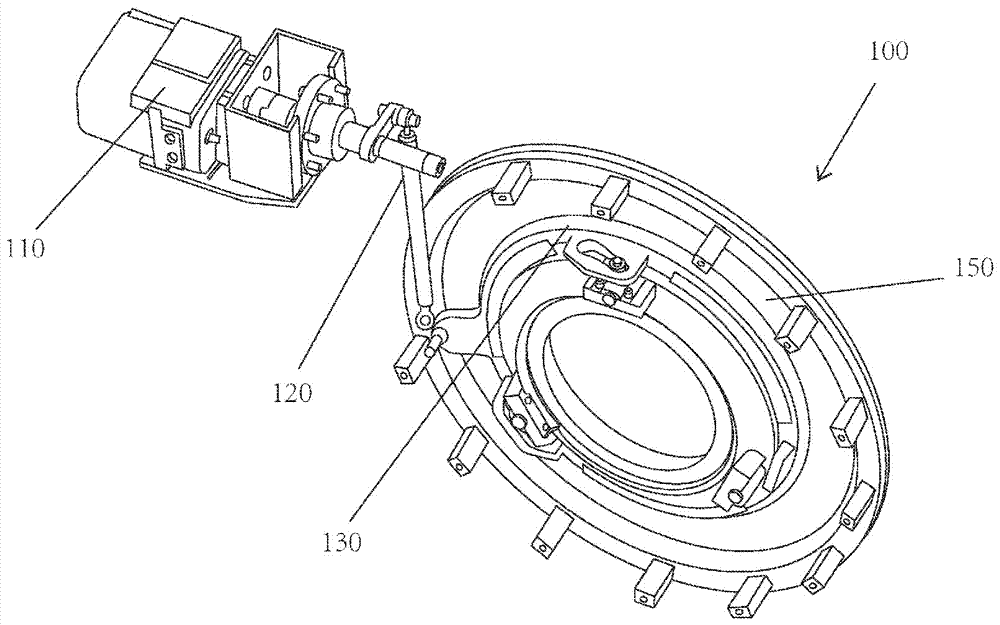

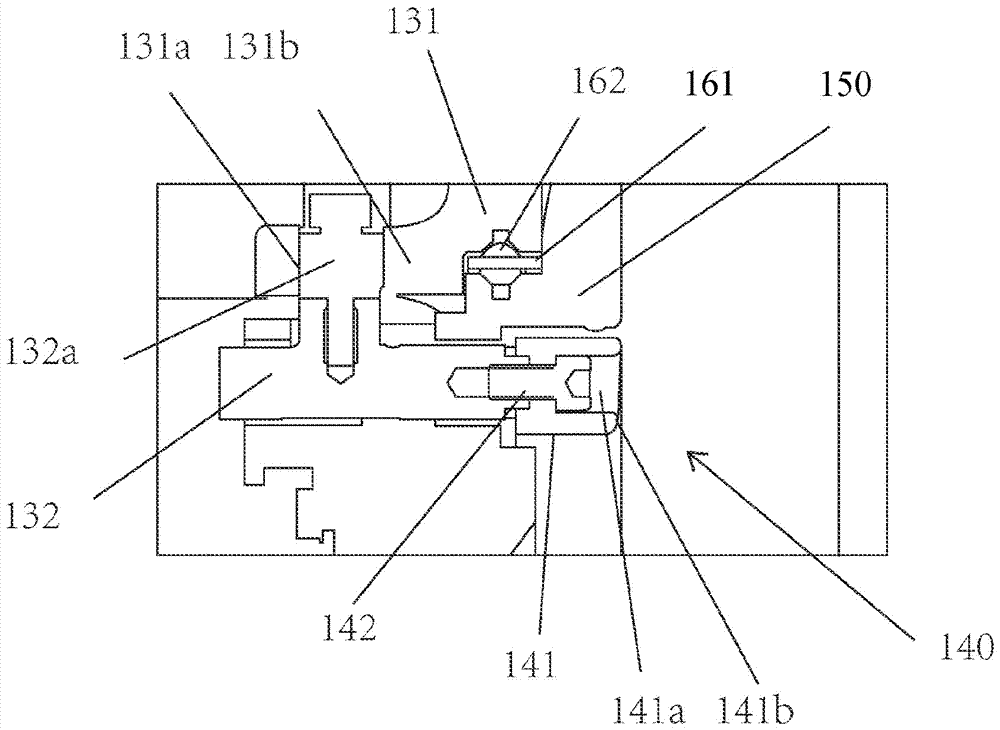

[0014] see figure 1 and figure 2 , which shows an embodiment of a diffuser 100 for a centrifugal compressor. Wherein, the diffuser 100 includes a driving component 110 , a transmission assembly 120 , an adjustment assembly 130 , a slide valve assembly 140 and a rear wall 150 . Wherein, the transmission assembly 120 is used to transmit the power generated by the driving part 110 to the adjustment assembly 130, the adjustment assembly 130 can reciprocate in the circumferential direction relative to the rear wall 150, and drive the slide valve assembly 140 to reciprocate in the axial direction; wherein, the adjustment Ball bearing 160 is provided between assembly 130 and rear wall 150 (in Figure 4 shown in ). This arrangement combines the existing structure of the diffuser to better realize the intervention of the mechanism for adjusting the width of the flow channel; and realizes the low-friction fit between the adjustment assembly 130 and the rear wall 150 through the ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com