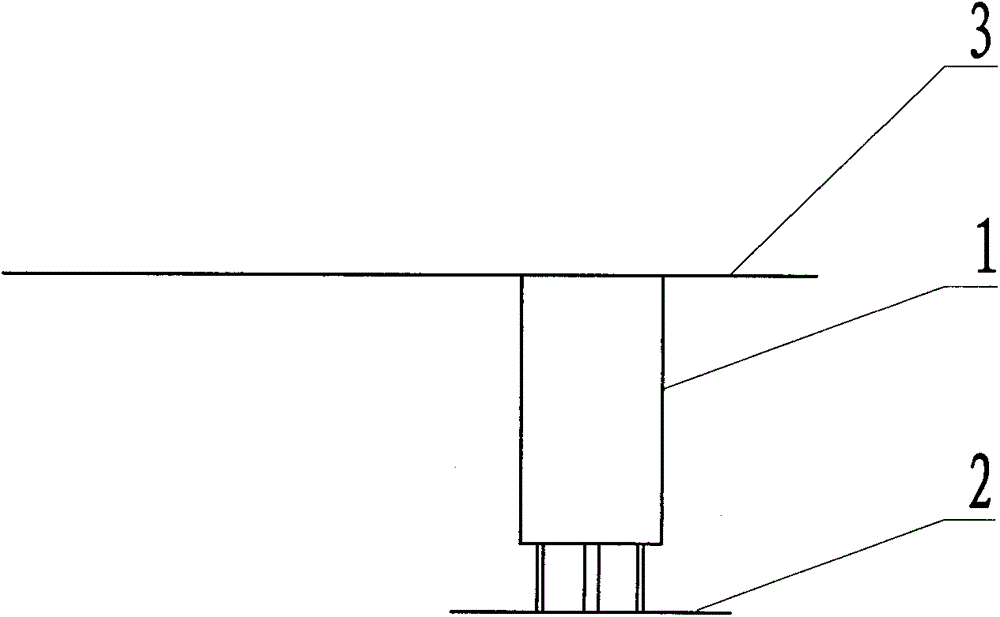

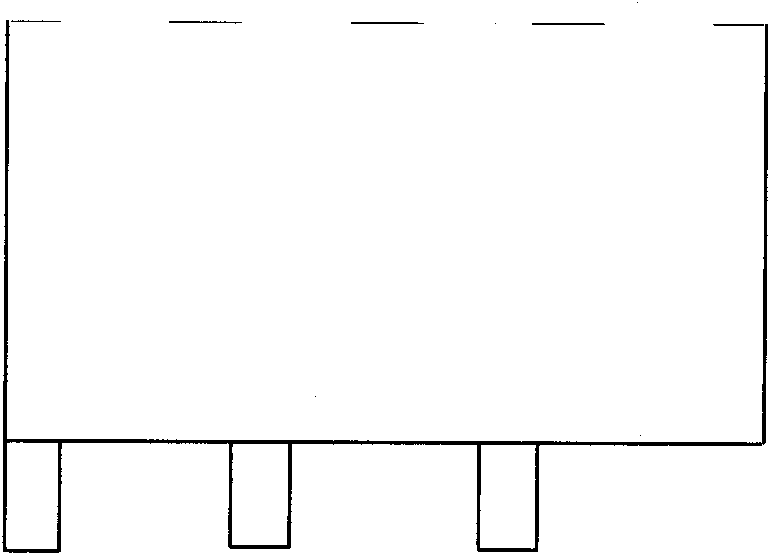

Suspended downcomer for a liquid-liquid extraction tower

A downcomer, hanging technology, applied in liquid solution solvent extraction, inorganic chemistry, non-metallic elements, etc., can solve the problems of reduced tray efficiency, unsatisfactory production, and lack of operational flexibility in liquid-liquid extraction towers, and achieves improved efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

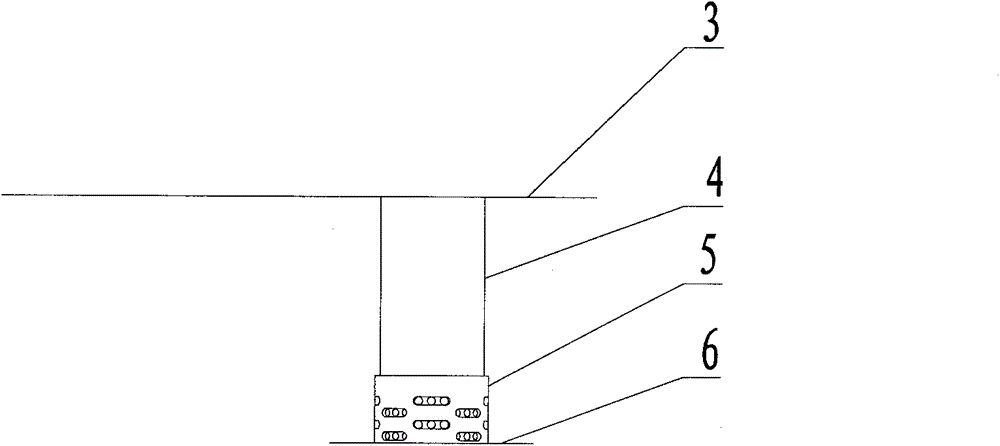

[0025] The sieve plate extraction tower adopting the downcomer shown in Figure 4~Figure 5 is applied to the extraction process in the hydrogen peroxide process produced by the anthraquinone method, when the operating conditions (working fluid flow, deionized water flow, extractant flow, When the concentration of hydrogen peroxide in the working solution and the concentration of hydrogen peroxide in the extract) change greatly, the operating condition data is shown in Table 1, and the results of the examples are shown in Table 2.

[0026] Table 1 Operating condition data

[0027]

[0028] Table 2 embodiment result

[0029]

[0030] The data in Table 2 shows that: the sieve plate extraction tower designed with the downcomer structure as shown in Figure 4 to Figure 5 is applied to the extraction process in the production of hydrogen peroxide by the anthraquinone method, when the working fluid flow, deionized water flow , extraction liquid flow rate, working liquid hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com