Planting frame capable of achieving automatic swing inclination and swing erection

A planting rack and automatic technology, applied in the field of planting racks, can solve the problems of different sizes of finished plants, asynchronous root growth and development, nutrient solution spillage, etc., and achieve the effect of keeping clean and tidy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

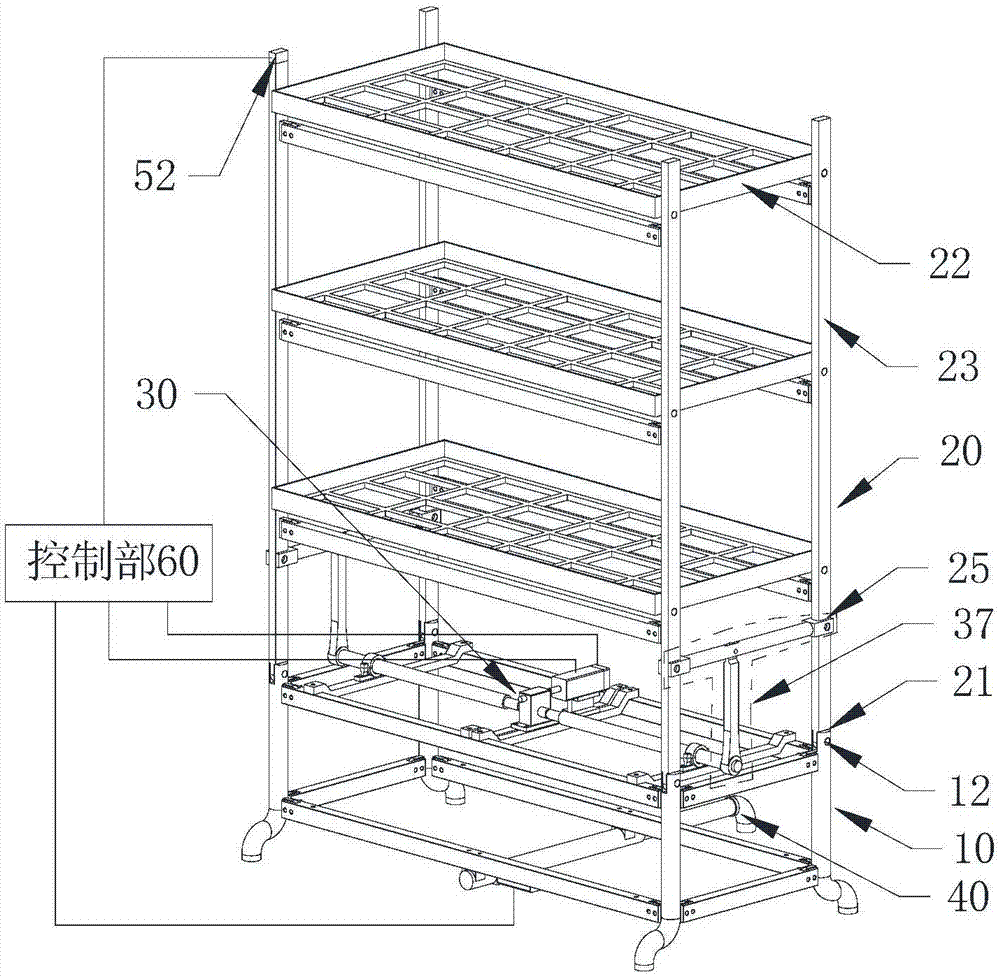

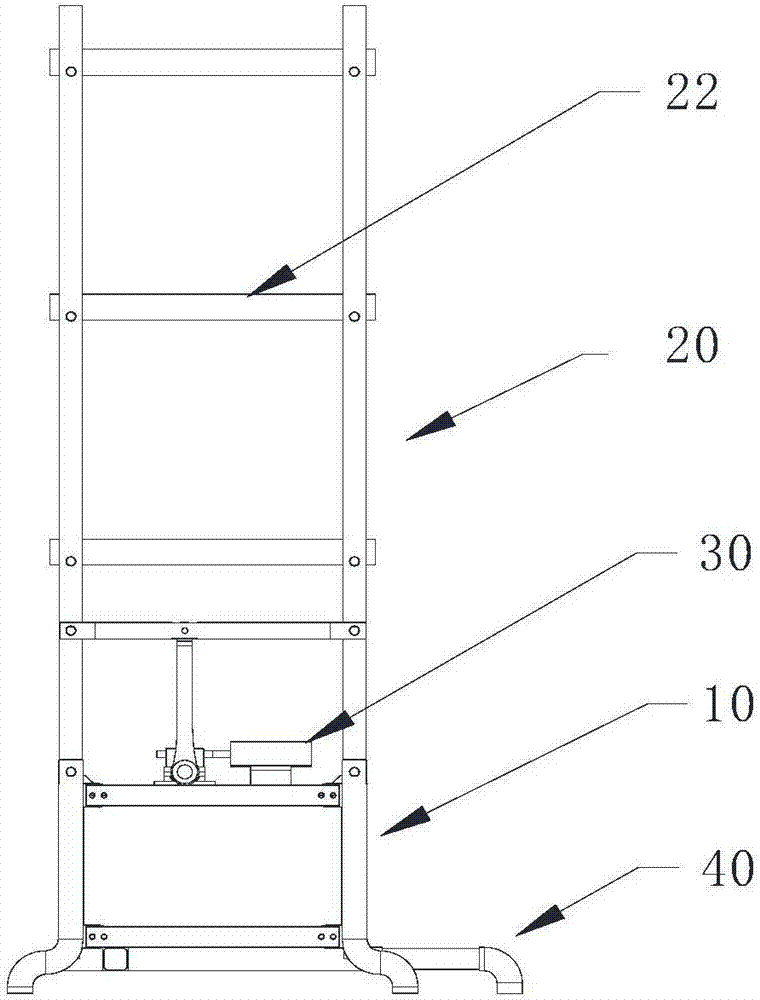

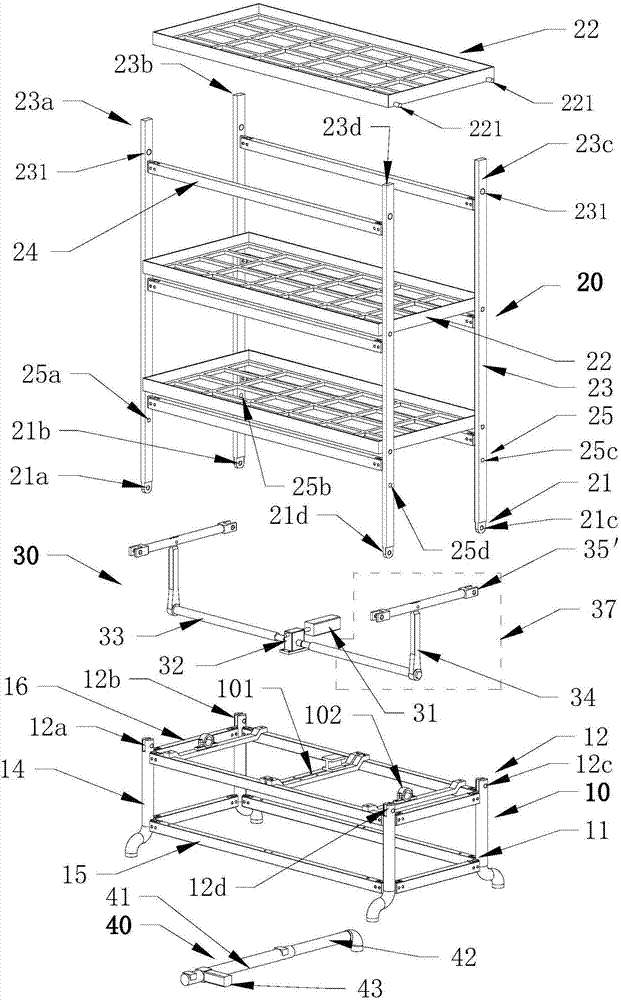

[0045] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the drawings and specific embodiments.

[0046] The expression of the spatial orientation in the text is hereby agreed. The spatial orientation is based on the spatial orientation of the first drawing in the implementation mode. “Front” refers to the side of the drawing closest to the reader, and “rear” refers to the attached drawing. On the side farthest from the reader, "left" refers to the left side of the drawing, "right" refers to the right side of the drawing, "vertical" refers to the drawing from front to back or back to front, and "horizontal" refers to the attached In the figure, from left to right or from right to left, "inner" refers to the inside of the outline of the drawing, and "outer" refers to the outside of the outline of the drawing.

[0047] A planting stand with automatic swing tilt and swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com