Novel anti-clogging reactor

An anti-clogging, reaction kettle technology, applied in chemical/physical/physical-chemical stationary reactors, detailed information of chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc. Damage, affecting the stirring function of the reactor, etc., to achieve the effect of ensuring the stirring function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

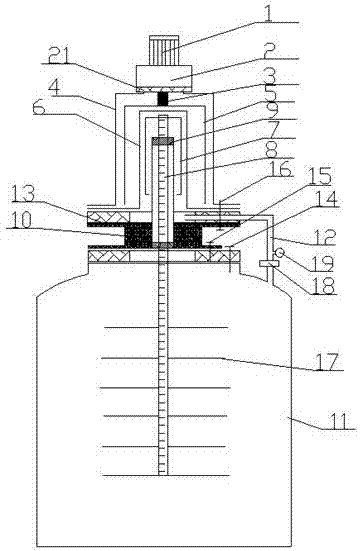

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] This embodiment provides a novel anti-clogging reactor, such as figure 1 As shown, the reactor is mainly composed of a motor 1, a reducer 2, an output shaft 3, an outer cover 4, an outer magnetic cylinder 5, a sealing cover 6, an inner magnetic cylinder 7, a rotating shaft 8, a bearing 9, a bearing seat 10, and a flange 13 , kettle cavity 11, pipeline 12 and stirring blade 17, the motor 1 is connected to the top of the output shaft 3 through the reducer 2, and the bottom end of the output shaft 3 passes through the outer cover 4 and is connected to the outer magnetic cylinder 5 located in the outer cover 4, The top of the outer cover 4 is fixedly connected with the reducer 2 through the third flange 21, the sealing cover 6 is located in the outer magnetic cylinder 5, the inner magnetic cylinder 7 is located in the sealing cover 6, and the inner magnetic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com