Sesame oil production cycle oil filtering device

An oil filter device and a technology for sesame oil, which are used in the production of fat oil/fat, fat production, and fat oil/fat refining, etc., can solve the problems of clean fragrance, high labor intensity, inability to realize continuous production, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

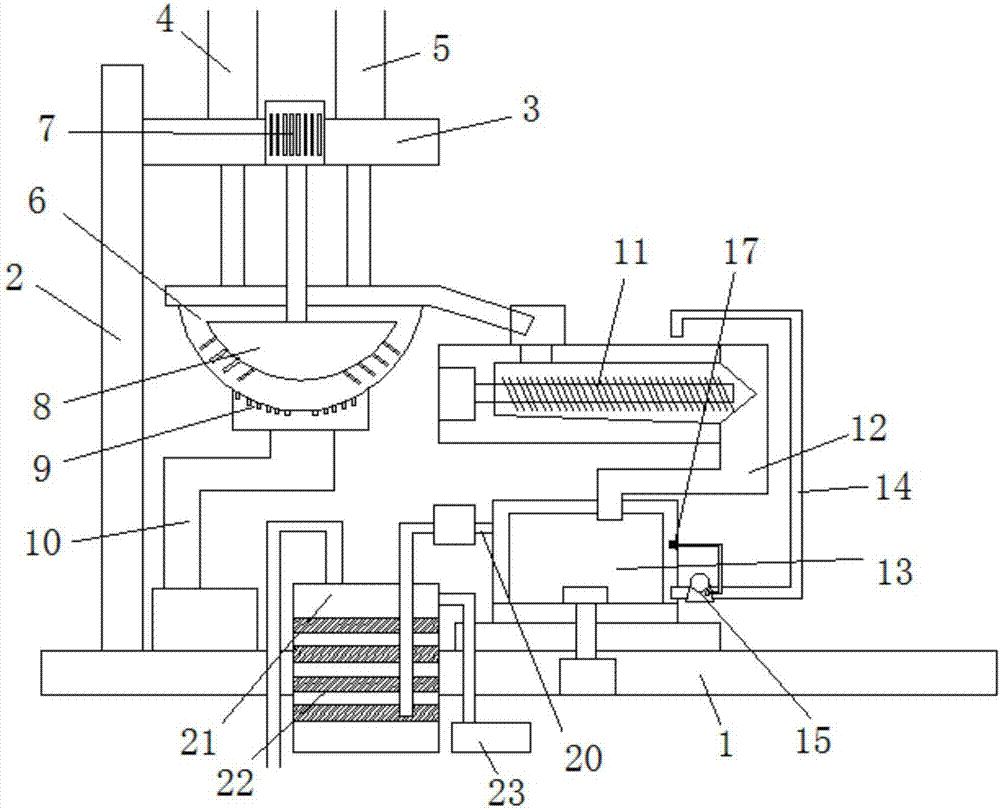

[0011] Referring to the accompanying drawings, a circulating oil filter device for sesame oil production includes a machine base 1, a column 2 is fixedly installed on the machine base 1, a beam 3 is fixedly installed on the column 2, and a left , two right adjustment cylinders 4,5, the piston rod lower ends of the left and right two adjustment cylinders 4,5 are respectively hinged to the two ports of the stir frying pan 6, and the two ends of the stir fry pan 6 are positioned between the left and right adjustment pistons. Under the action of the bar, the material can be unloaded. A motor 7 is arranged between the left and right regulating cylinders 4 and 5. The lower end of the rotating shaft of the motor 7 is connected with a frying shovel 8. There is a slag discharge hole 9, the slag discharge hole 9 is connected to the dust extraction pipeline 10, a screw extrusion tank 11 is provided on one side of the stir frying pan 6, and an oil guide pipeline is provided on one side of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap