Shoe sole skid resistance tester

A testing machine and driving mechanism technology, applied to footwear, foot or shoe last measuring devices, clothing, etc., can solve the problems of inaccurate anti-skid data, difficulty in testing results conforming to the actual situation, and narrow application range, and achieve a variety of realizations. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

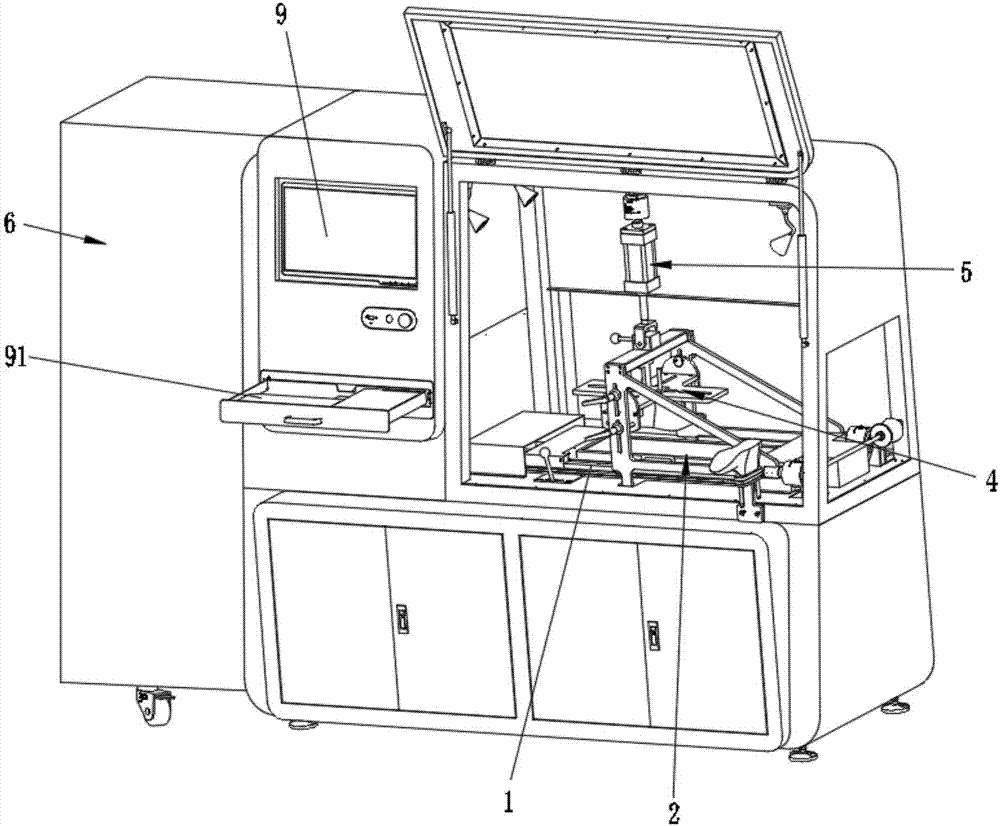

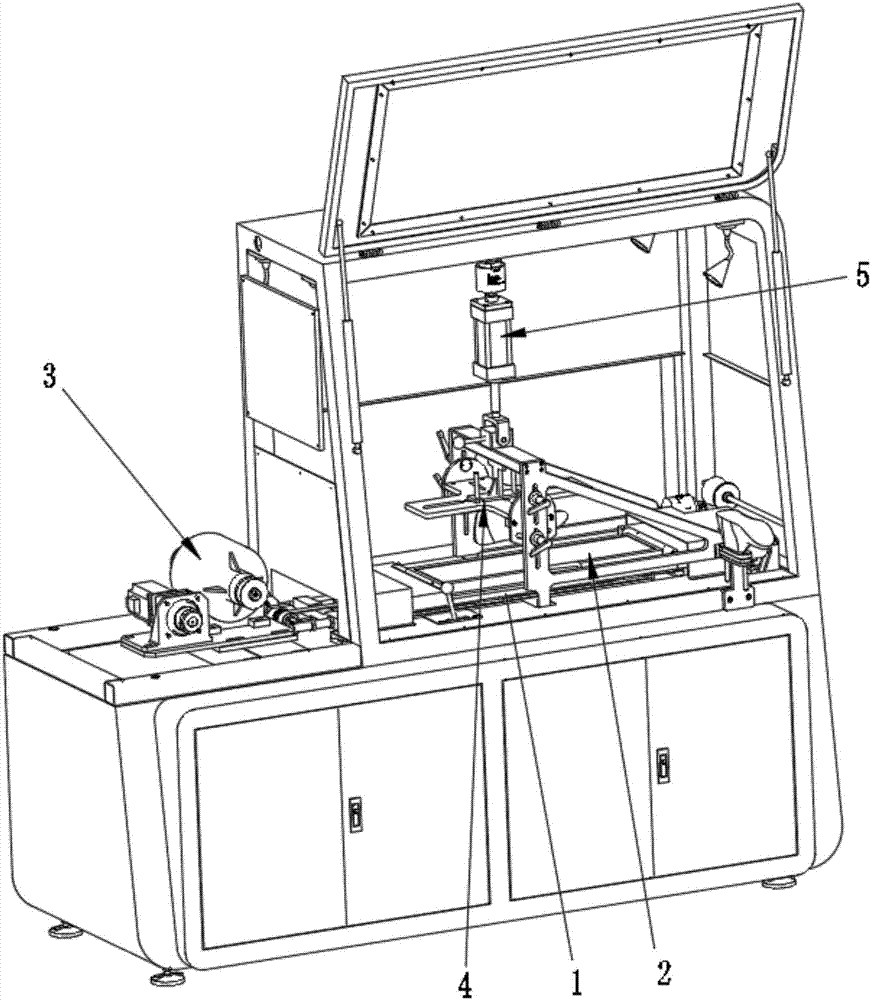

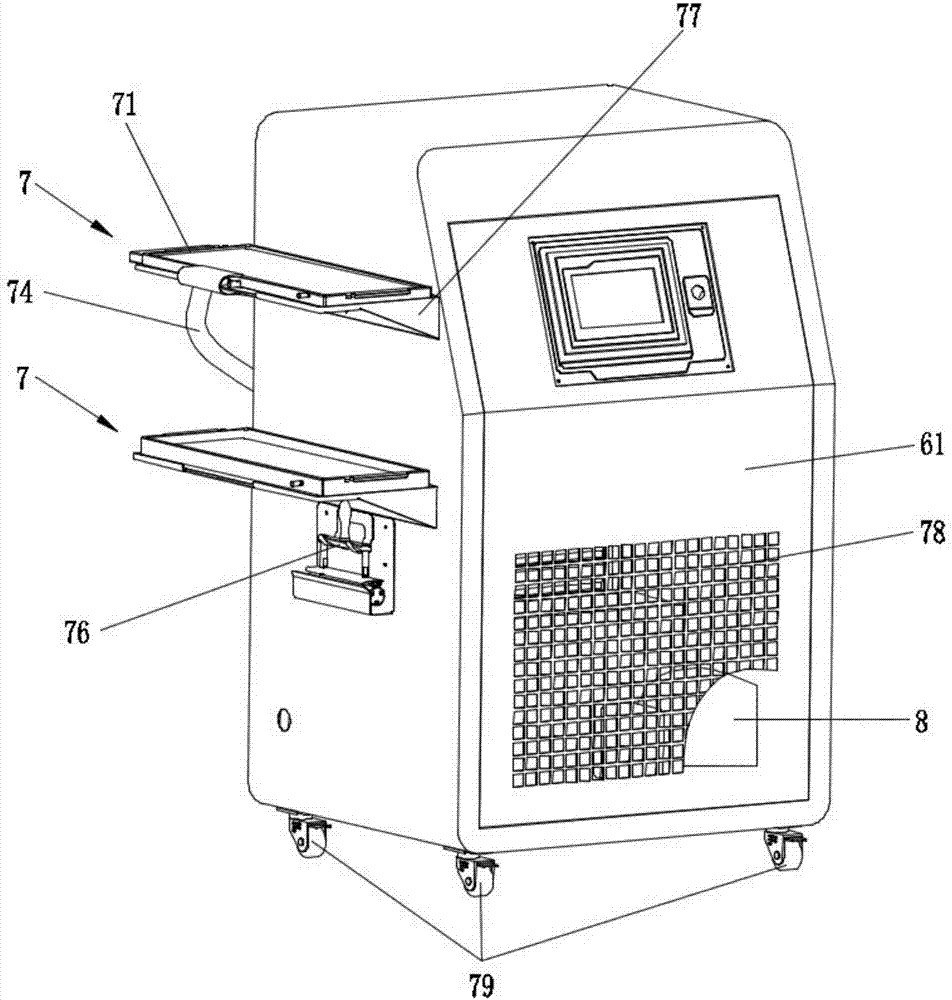

[0034] Such as figure 1 and figure 2 As shown, a shoe sole anti-slip testing machine provided by the present invention includes a workbench 1, a friction assembly 2 slidably arranged on the workbench 1 and used for anti-skid testing, and a first drive mechanism 3 for driving the friction assembly 2 to reciprocate, The clamp assembly 4 that is movable on the workbench 1 and used to clamp the sample shoe from the outside world, the friction assembly 2 is used to resist the sample shoe clamped by the clamp assembly 4, and the clamp assembly 4 is used to adjust the sample shoe and the friction assembly 2 The angle between them is used to drive the second drive mechanism 5 for moving the grippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com