Special mud-push spiral bearing seat for sewage treatment centrifuge

A technology for sewage treatment and centrifuges, used in centrifuges and other directions, can solve problems such as bearing damage, wear of spiral sinking spiral cavity, and easy blocking of drains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

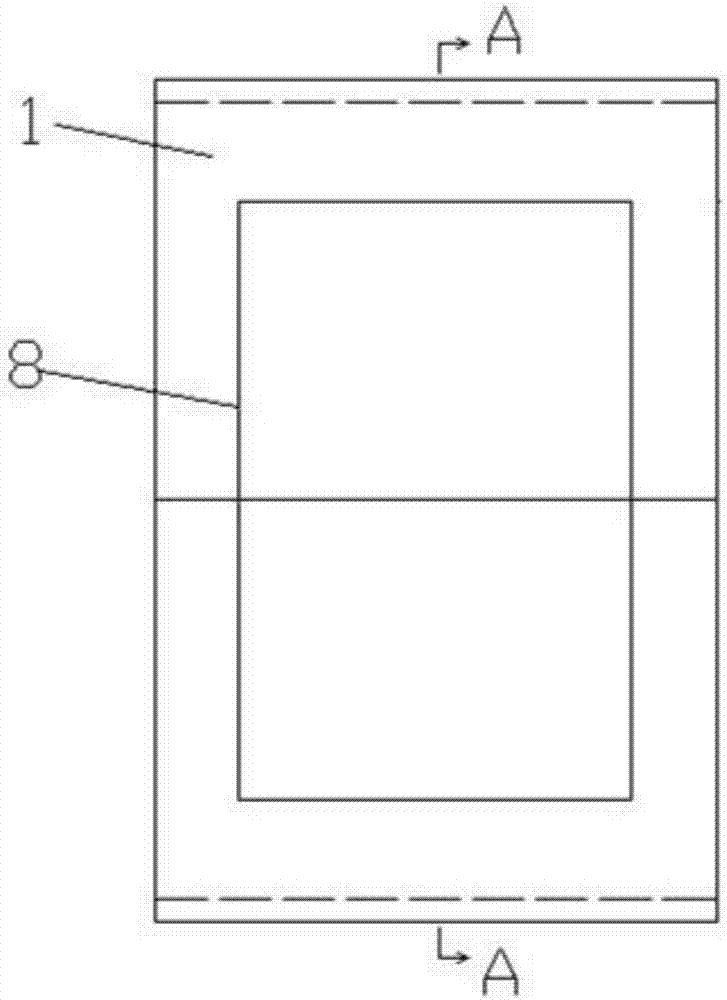

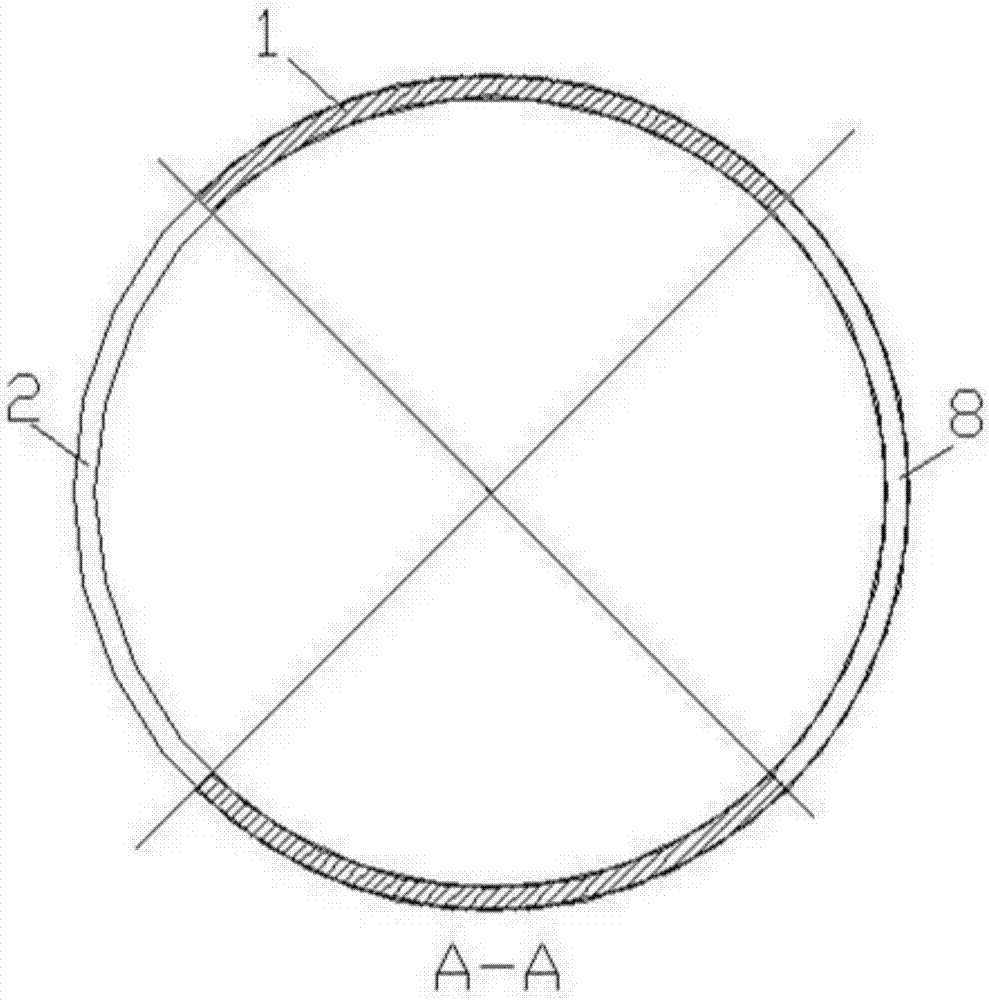

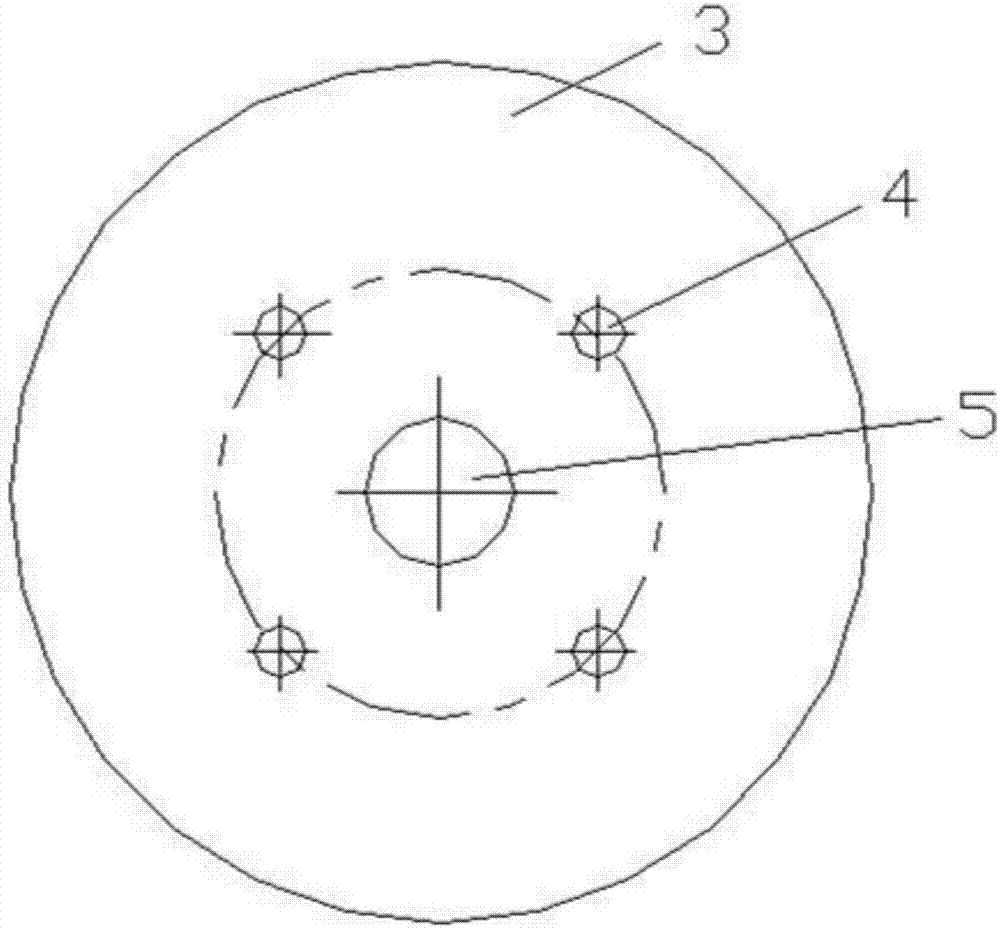

[0014] Attached below Figure 1-4 The specific embodiment of the present invention will be further described.

[0015] A mud-pushing screw bearing seat specially used for sewage treatment centrifuges, including a bearing bracket, a circular plate and a short shaft; the bearing bracket includes a frame body 1, which is a hollow cylinder structure, and the two sides of the frame body 1 are symmetrical A disassembly groove 2 and a discharge groove 8 are provided, and the opening angles of the disassembly groove 2 and the discharge groove 8 are both 90°; Four bolt holes 4 are provided, and the four bolt holes 4 are distributed around the shaft lead-out hole 5; the short shaft includes a shaft body 6, and the shaft body 6 includes a large cylindrical end and a small cylindrical end that are sequentially connected into an integral structure. Connecting groove 7 is arranged; The large cylindrical end of short shaft is installed in the bearing bracket, and circular plate is sleeved o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com