Equipment and its manufacturing process for manufacturing concrete pressure pipes with internal mold rigid expansion

A technology for concrete and pressure pipes, used in manufacturing tools, ceramic molding machines, ceramic molding cores, etc., can solve problems such as large pipeline water transmission and power loss, uneven inner surface of pipes, poor interface sealing, etc., and achieve quality accidents. Reduced, smooth inner surface, frequent damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to better understand the improvements made by the present invention over the prior art, the present invention will be described in detail below in conjunction with specific embodiments.

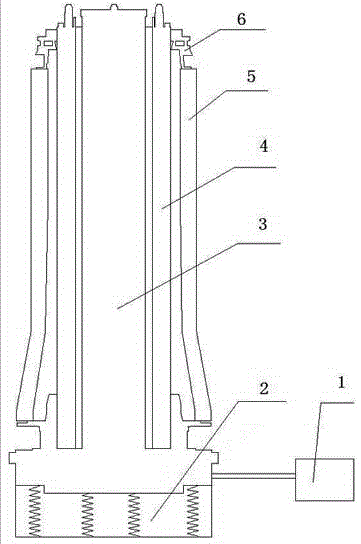

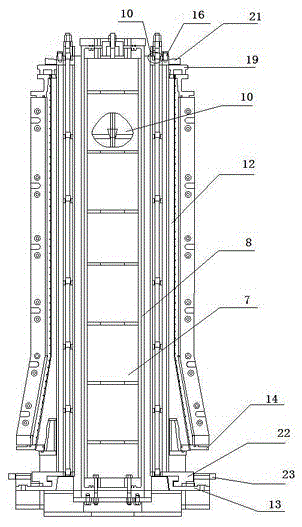

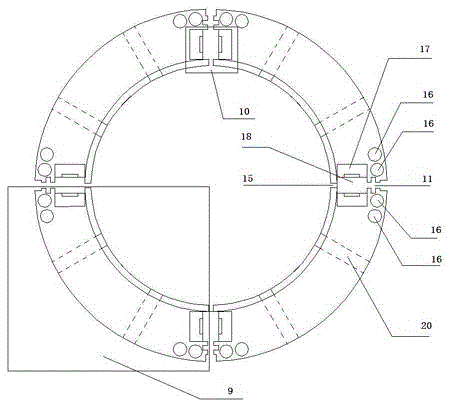

[0057] Such as figure 1 , figure 2 , image 3 As shown, the equipment for rigid expansion of the inner mold to make concrete pressure pipes is composed of a booster control room 1, a vibrating table 2, a booster device 3, an inner mold 4, an outer mold 5, and a sealing device 6, a booster device 3, an inner mold 4. The outer mold 5 is in an independent state, and the booster device 3 is composed of a booster device core tube 7 that is injected with water and a booster device rubber sleeve 8 jacketed on the booster device core tube 7; the inner mold 4 is a rigid inner The mold is assembled between the boosting device 3 and the outer mold 5. The rigid inner mold is composed of multiple arc-shaped expandable rigid members 9 evenly distributed on the circumference, and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com