Wide surface processing and shot-blasting mechanism

A technology of wide surface and shot blasting chamber, which is applied to the processing device of used abrasives, grinding/polishing equipment, abrasives, etc. It can solve the problems of low processing efficiency, rollover, and the failure of the whole machine to improve efficiency. , increase the width, reduce the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

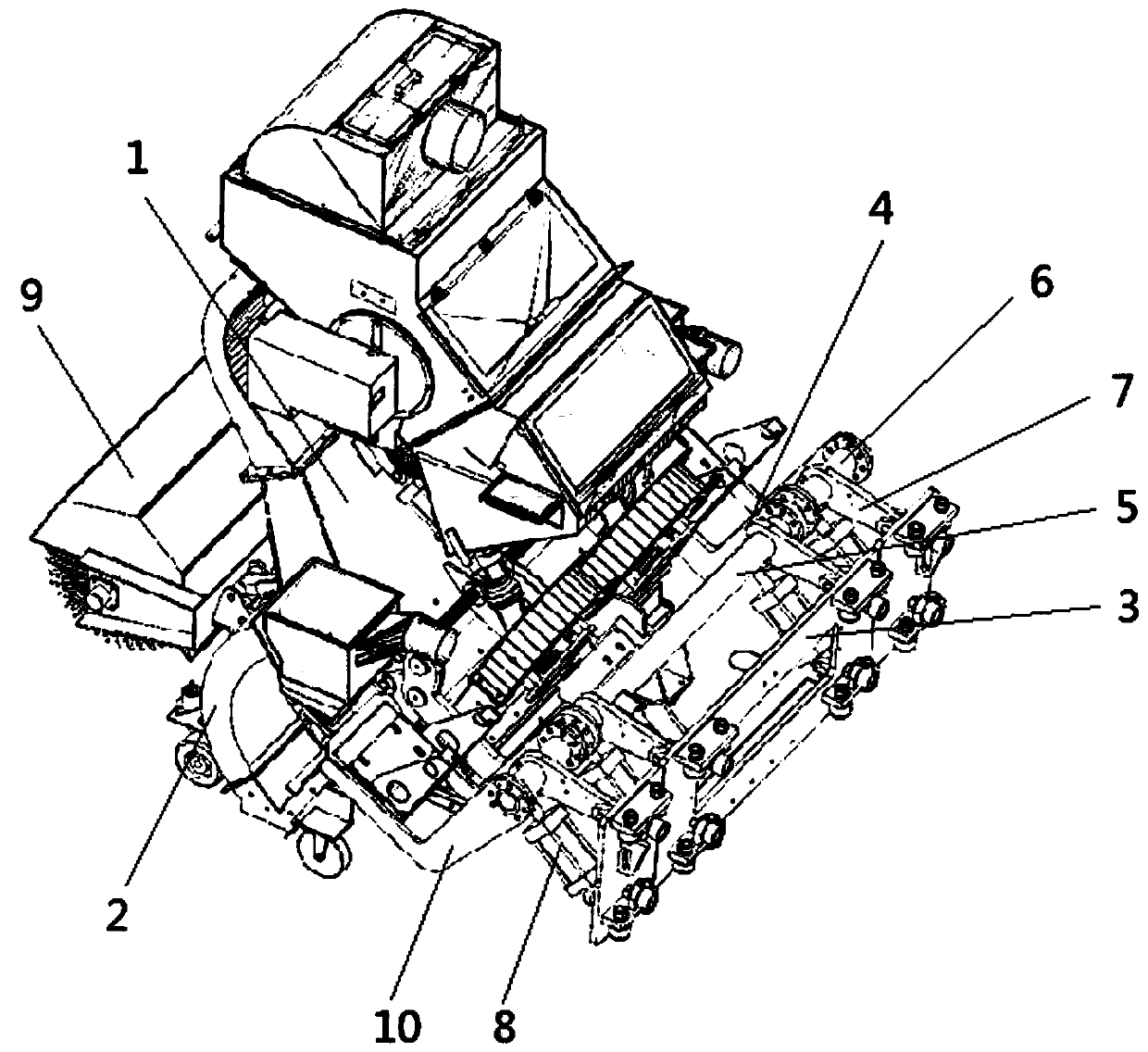

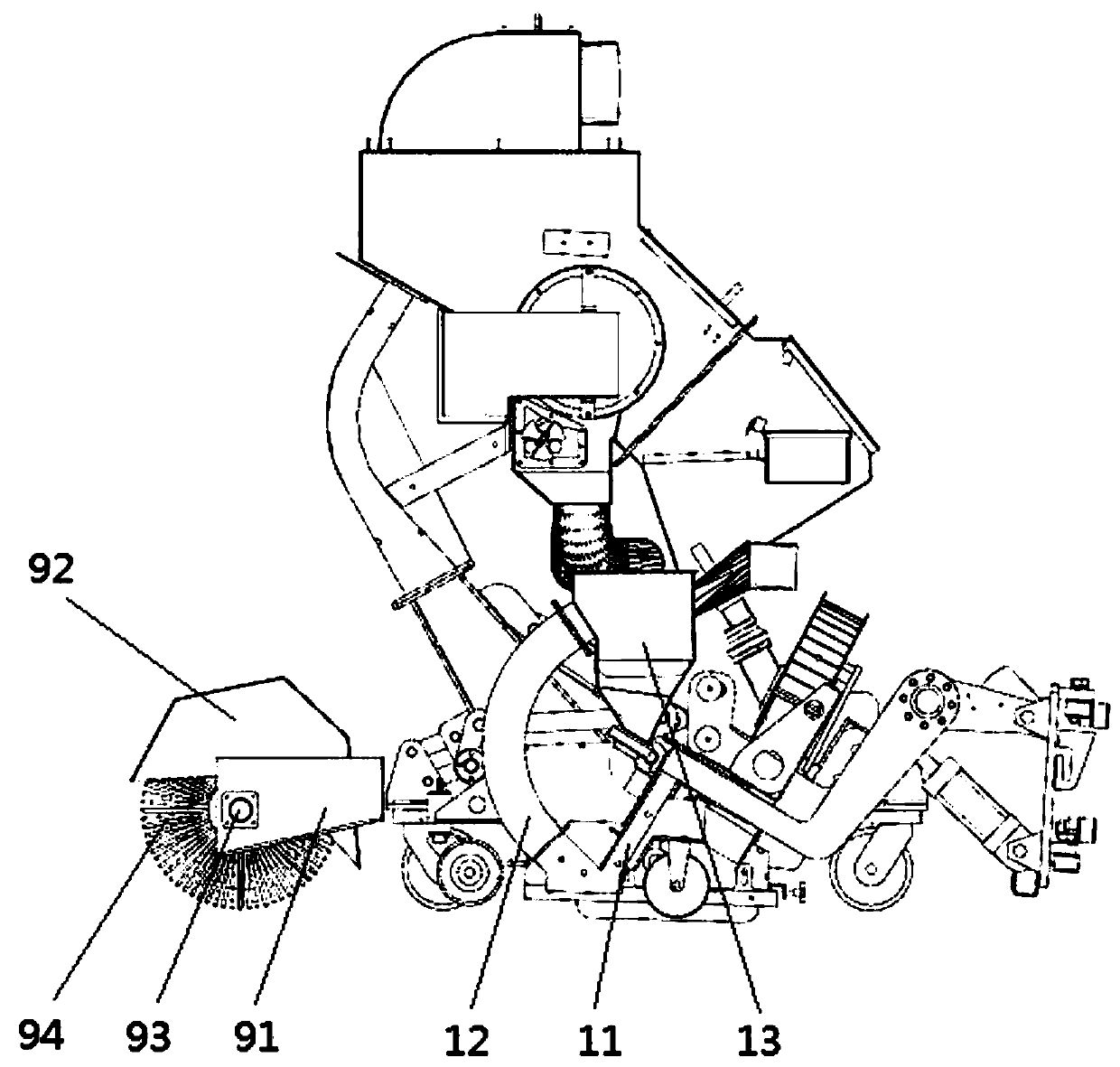

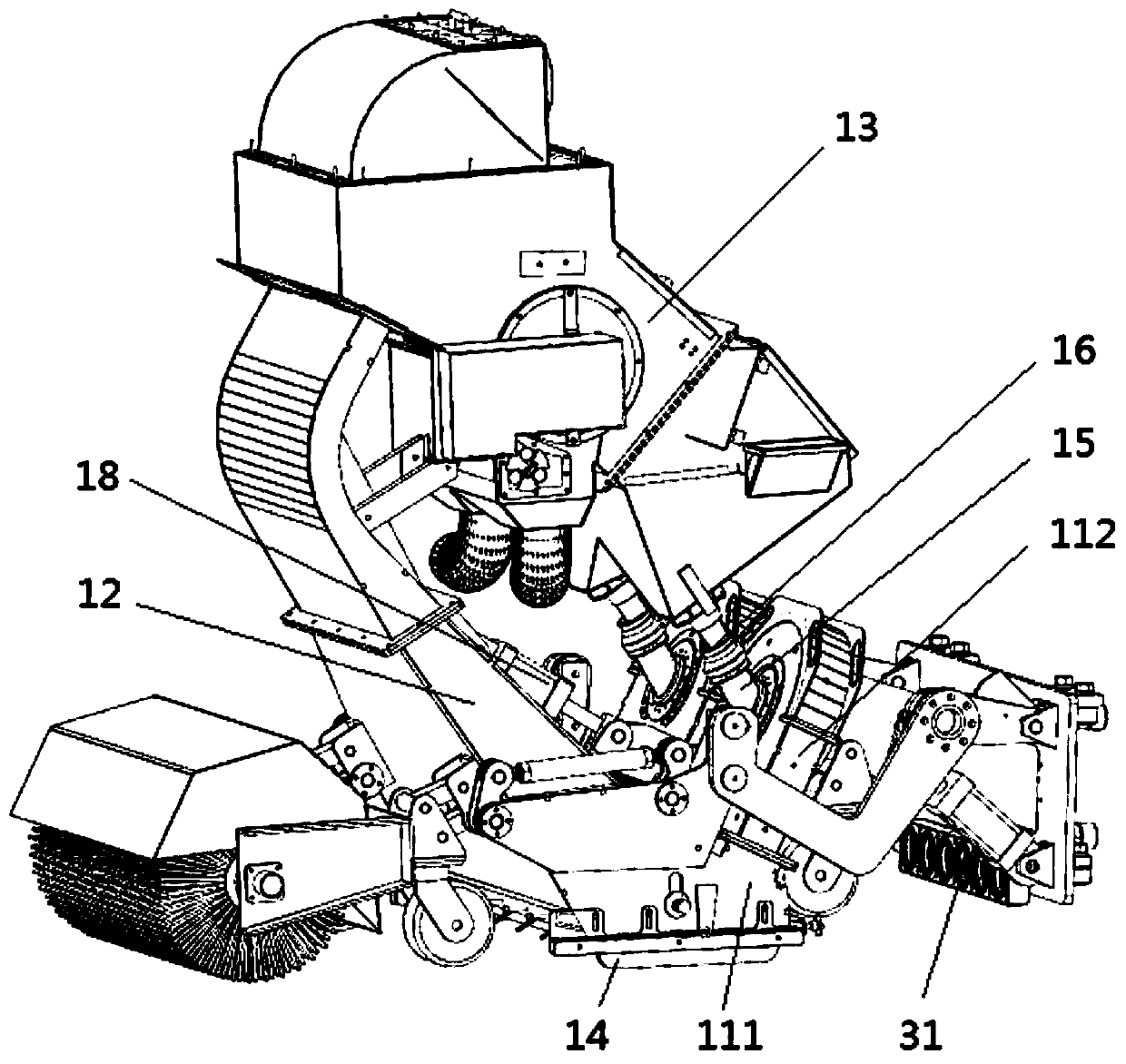

[0032] See attached figure 1 The wide-surface processing shot blasting mechanism provided in this embodiment includes a mounting frame, a main shot blasting unit 1 and at least one set of side shot blasting units 2. A set of side shot blasting units 2 and a set of main shot blasting units 1 are connected to each other through the mounting frame The power unit connection can also achieve the purpose of greatly increasing the processing area and processing surfaces close to the wall or corner. Compared with the existing vehicle-mounted front-side shot blasting mechanism, which only has the form of the main shot blasting unit, it not only removes the meaningless side shift unit structure, but also ensures the more reliable rigidity between the front-end main and side shot blasting units and the whole machine. Connection to prevent large leakage of steel shots during work due to unstable connection, and the combination of the side shot blasting unit 2 and the main shot blasting unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com