Energy-saving quality-improving type adipic acid crystallizer discharging device and discharging process

A technology of discharging device and crystallizer, which is applied in the direction of solution crystallization, chemical industry, sustainable manufacturing/processing, etc. It can solve the problems of low discharging efficiency, mechanical wear, complicated operation, etc., achieve short replacement cycle and eliminate particle size Interference, the effect of ensuring the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

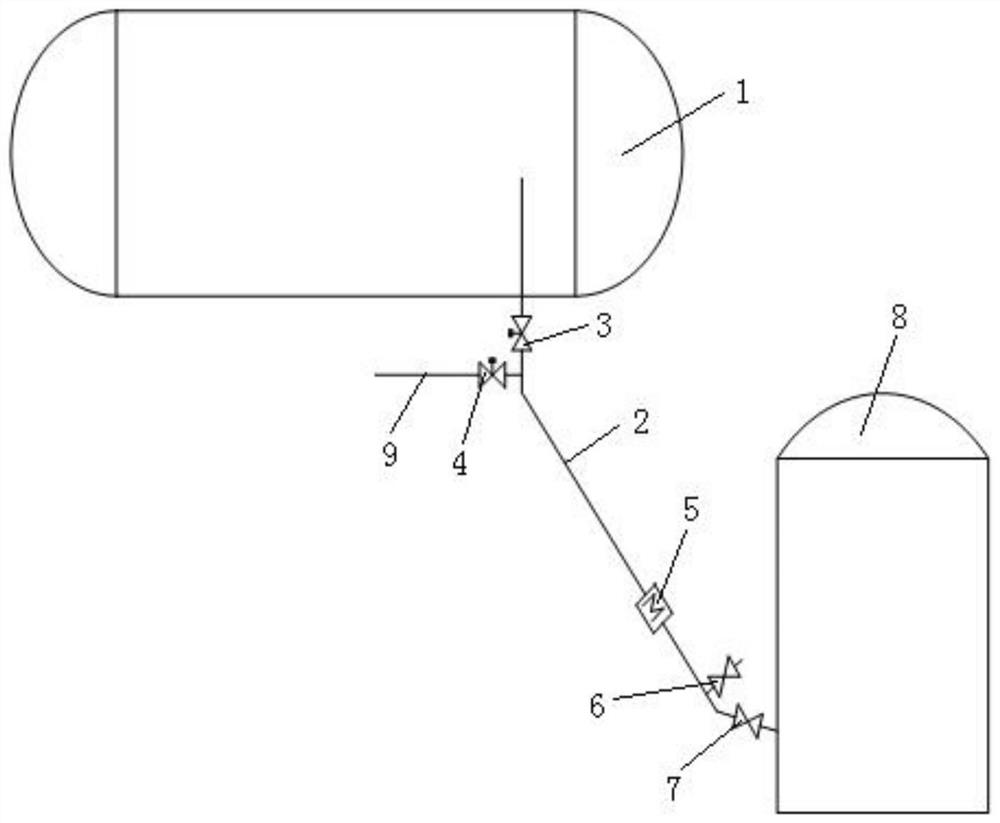

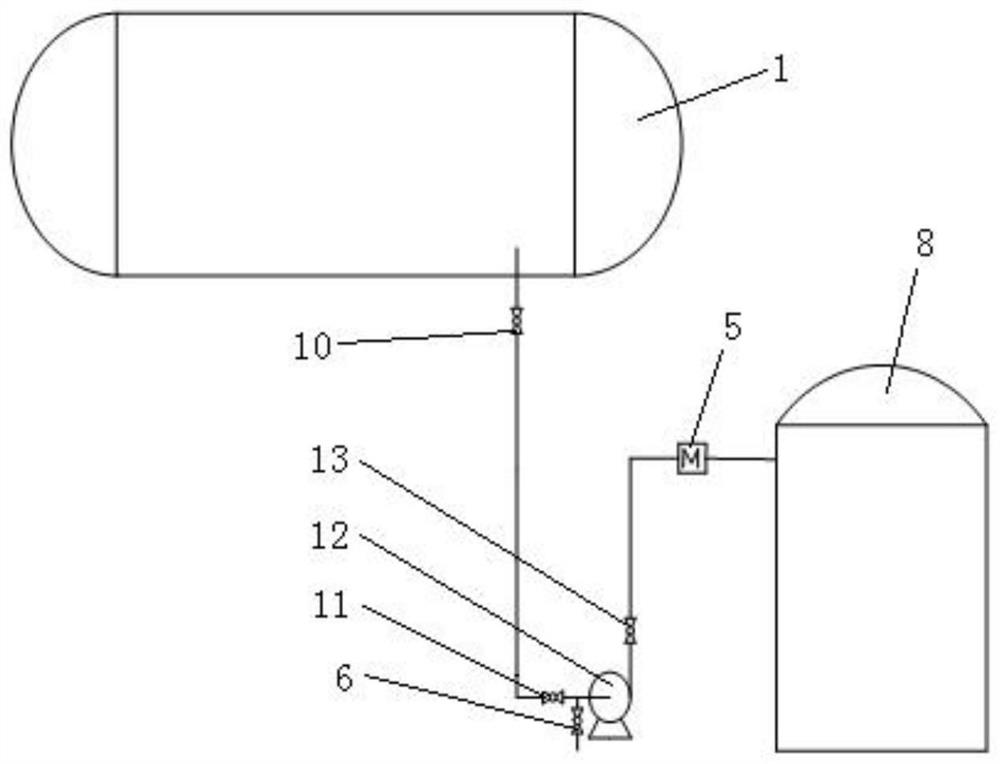

[0029] Such as figure 1 As shown, an energy-saving and quality-improving type adipic acid crystallizer discharge device includes a crystallizer 1 and a receiving tank 8, and a stainless steel pipeline 2 with a certain slope is arranged between the crystallizer 1 and the receiving tank 8, A discharge solenoid valve 3, an electromagnetic flowmeter 5, a shower guide 6 and a hand valve 7 are sequentially installed on the stainless steel pipeline 2, and a hot water pipeline 9 is welded below the discharge solenoid valve 3, and the hot water pipeline 9 One end of the pipe is connected with the stainless steel pipeline 2, and the other end of the hot water pipeline 9 is connected with the public hot water main pipe. The hot water solenoid valve 4 is installed on the hot water pipeline 9; The airtight pipeline is directly led from the last compartment of the crystallizer 1, and is directly connected to the bottom of the receiving tank 8 according to the characteristics of the shortes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com