Iron-storing notch of blast furnace

A blast furnace tapping and tapping ditch technology, applied in the direction of discharge device and the like, can solve the problems affecting the production efficiency of blast furnaces, short service life and high maintenance frequency, and achieve the effects of low cost, improved corrosion resistance and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

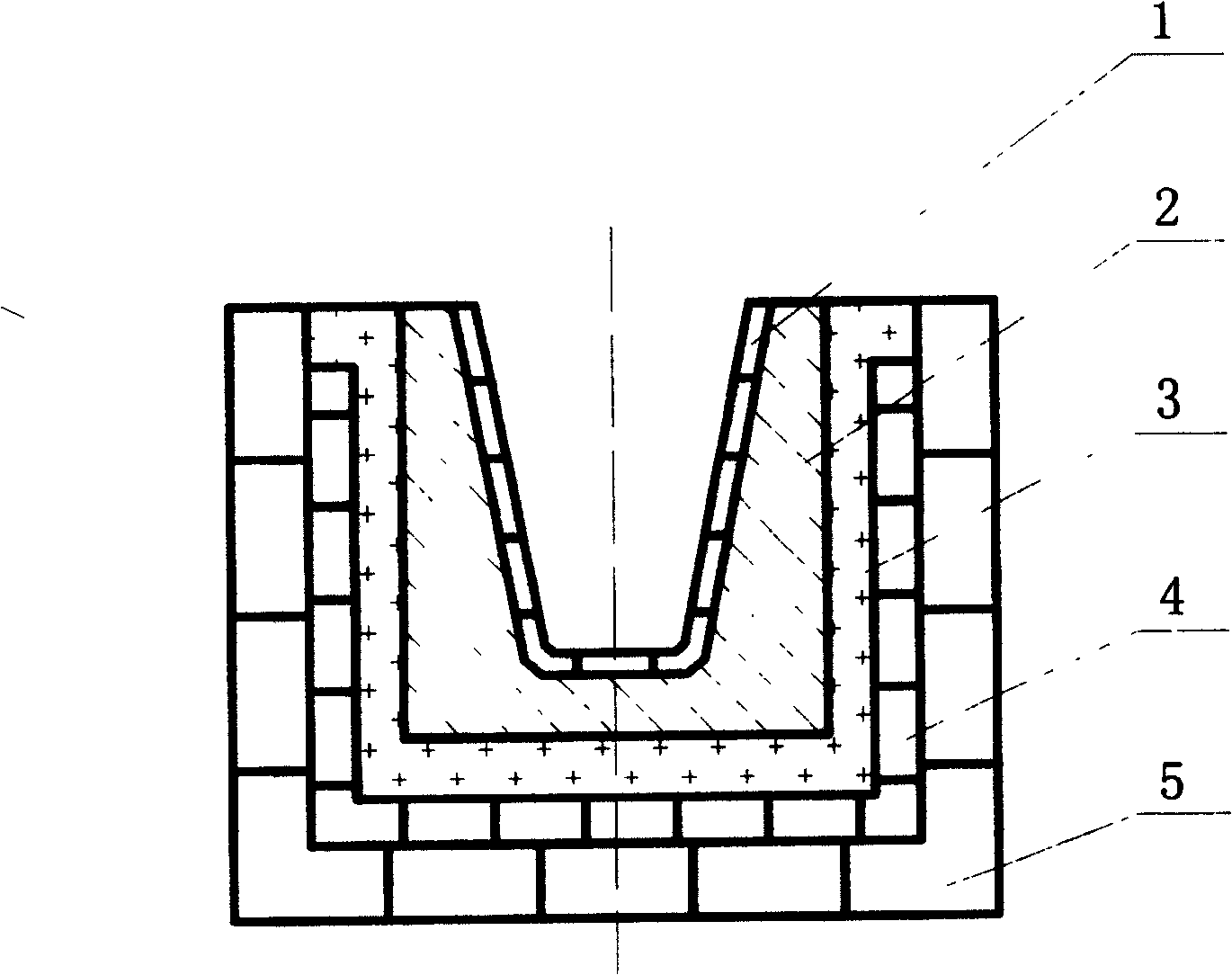

[0011] A iron storage type blast furnace iron trough, such as figure 1 As shown, it consists of the iron trench protective brick layer [1], the iron trench carbonaceous material working layer [2], the iron trench castable layer [3], the iron trench permanent brick lining [4], the iron trench heat insulation layer [5] Composition; the surface layer of the iron ditch is the iron ditch protective brick layer [1], the inner layer is the carbonaceous material working layer [2], the middle is the iron ditch castable layer [3], and the second outer layer is the iron ditch permanent The brick lining [4], the outermost layer is the iron ditch thermal insulation layer [5].

[0012] Each layer of the iron trench described in this embodiment plays an irreplaceable and mutually coordinated protective role: for example, the iron trench protective brick layer [1] is built with high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com