Mechanically operable valve and method for its manufacture

A technology for mechanical manipulation and manipulation elements, applied in the field of mechanically manipulated valves, which can solve the problems of inaccessibility, occupancy of valve housings, obstructions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

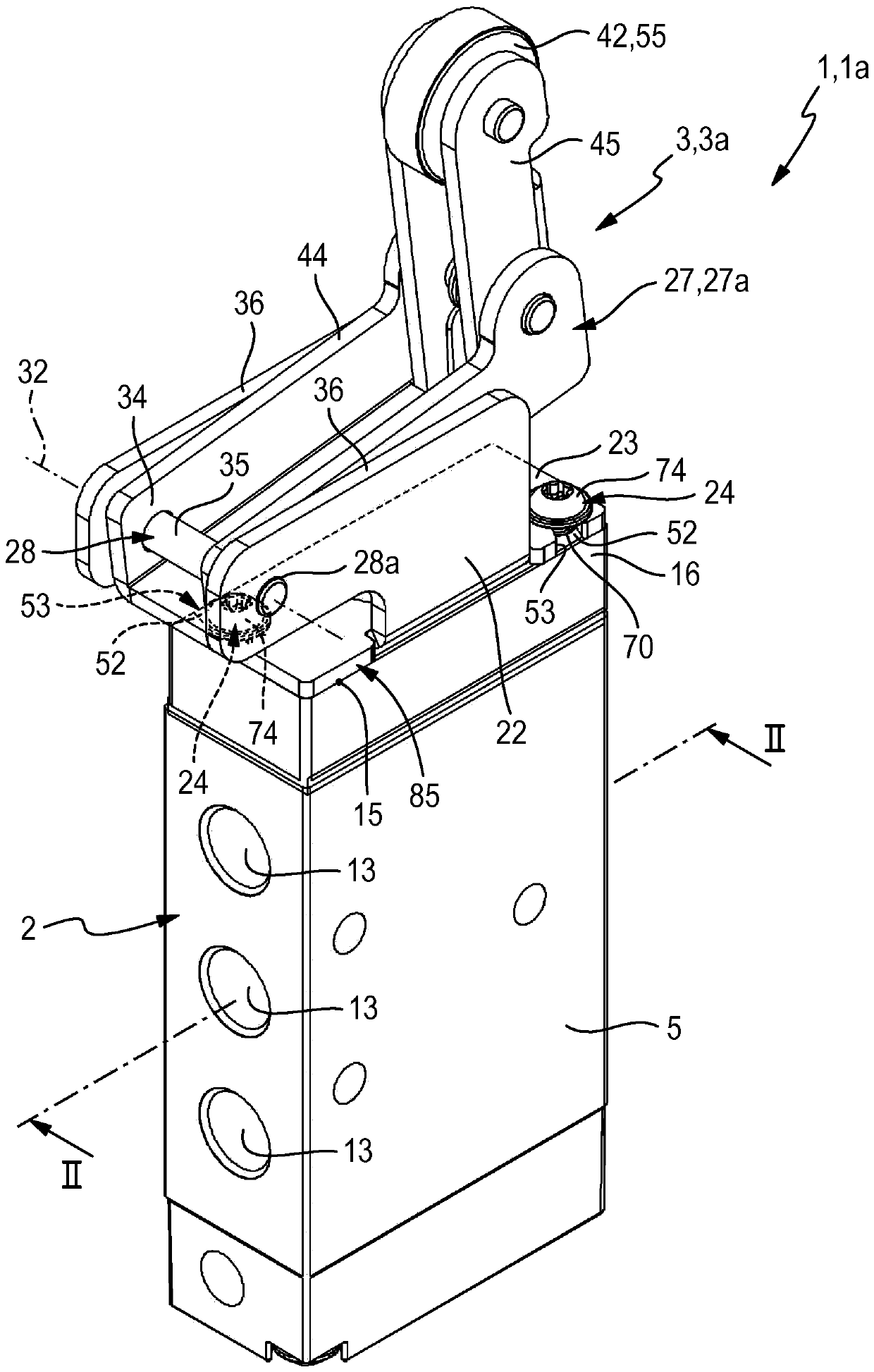

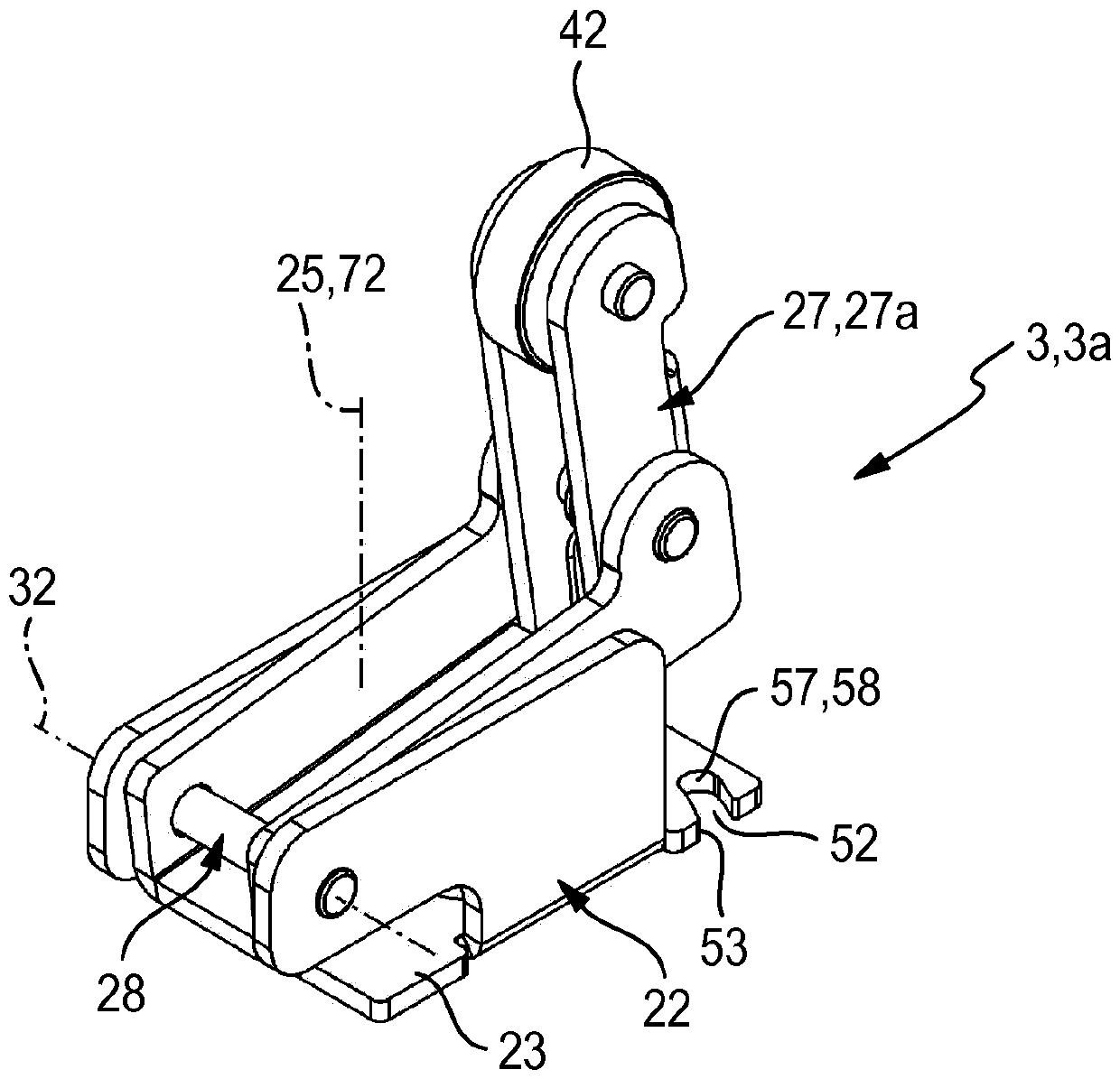

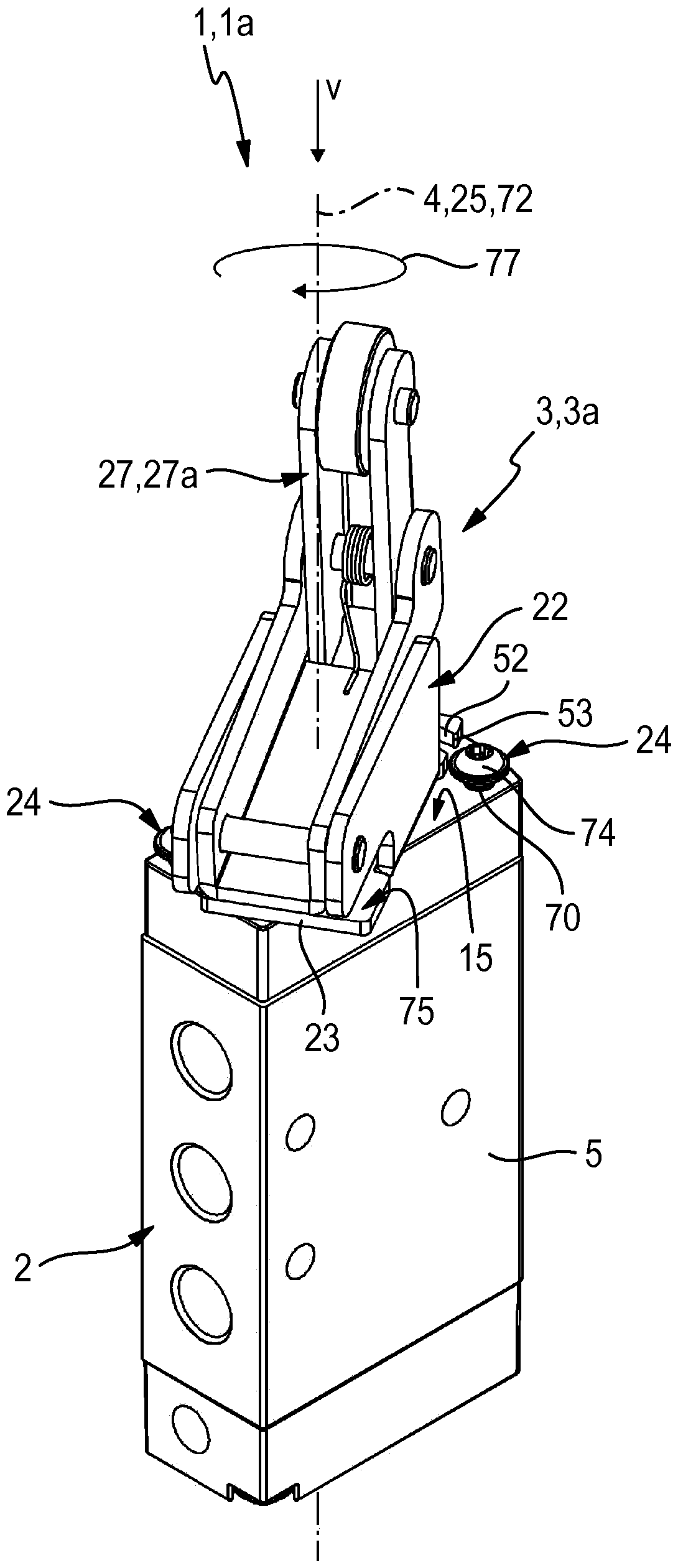

[0034] In the drawings, a mechanically actuatable valve, generally designated by the reference number 1 , is shown in the preferred embodiment of a roller lever valve 1 a.

[0035] The valve 1 has a valve unit 2 and an actuating device 3 for mechanically actuating the valve unit 2 , wherein the actuating device 3 is a roller lever actuating device 3 a in the exemplary embodiment.

[0036] The valve unit 2 has a longitudinal axis 4 . The actuating device 3 is preferably arranged on one of the two axial end sides of the valve unit 2 pointing in the axial direction of the longitudinal axis 4 .

[0037] The valve unit 2 has a valve housing 5 in which a valve chamber 6 is formed, in which a valve mechanism assembly 7 extends. The valve mechanism assembly 7 consists in this embodiment of a single valve mechanism 7a, but may also comprise a plurality of valve mechanisms. Within the scope of the switching movement 8 indicated by the double arrow, the valve mechanism assembly 7 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com