Multifunctional continuous working type labeling device

A multi-functional, labeling machine technology, applied in the field of machinery, can solve the problems of low work efficiency, low degree of automation, single product type, etc., to achieve the effect of improving labeling efficiency, high degree of automation, and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

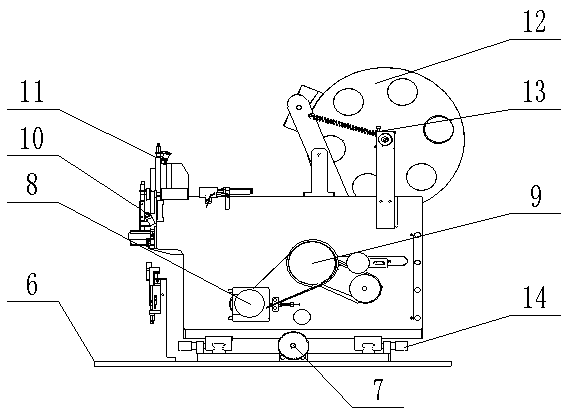

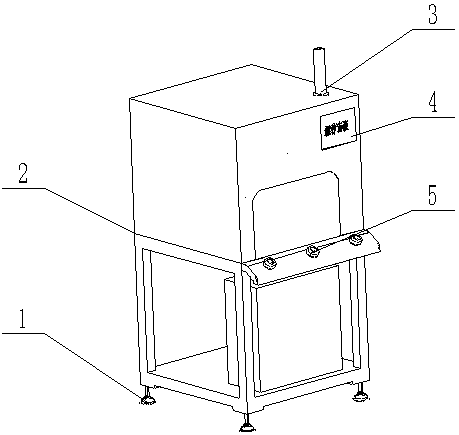

[0015] Such as Figure 1-Figure 2 As shown, a multifunctional continuous working type labeling device includes a base 1, a driving wheel 8, and a labeling machine 12. A casing 2 is arranged above the base 1, and an indicator light 3 and an operation panel 4 are arranged on the casing 2. The operation panel 4 The button 5 and the support plate 6 are set below, the motor 8 and the propeller 14 are set above the support plate 6, the driving wheel 8 and the driven wheel 9 are set above the propeller 14, the shear bar 10 is set above the driven wheel 9, and the shear bar 10 is set above A labeling main shaft 11 is provided, a labeling machine 12 is provided above the labeling main shaft 11, and a spring 13 is provided on one side of the labeling machine 12.

[0016] In this embodiment, the top of the base 1 is connected to the case 2 by hexagonal screws, the base 1 can make the device more sensitive, the connection between the case 2 and the indicator light 3 is screw connection, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com