A kind of preparation method of baby wipes

A technology for baby wipes and wet wipes, which is applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc. It can solve the problems of complex production process and unsuitability for large-scale production, and achieve simple preparation process and tight and smooth surface structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

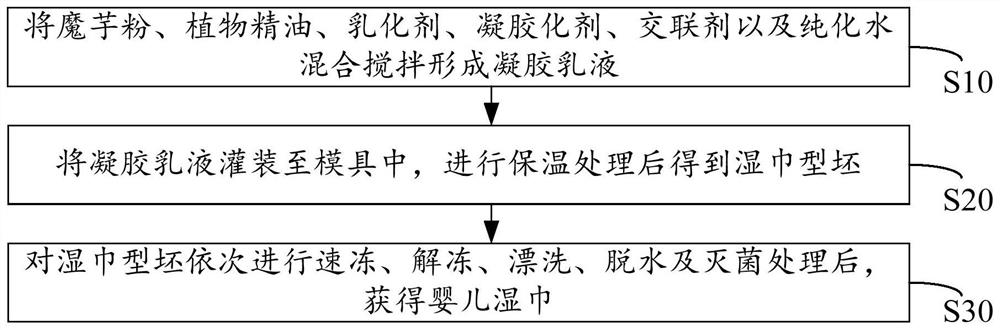

[0027] The present invention proposes a method for preparing baby wipes. In one embodiment of the method for preparing baby wipes provided by the present invention, the method for preparing baby wipes includes the following steps:

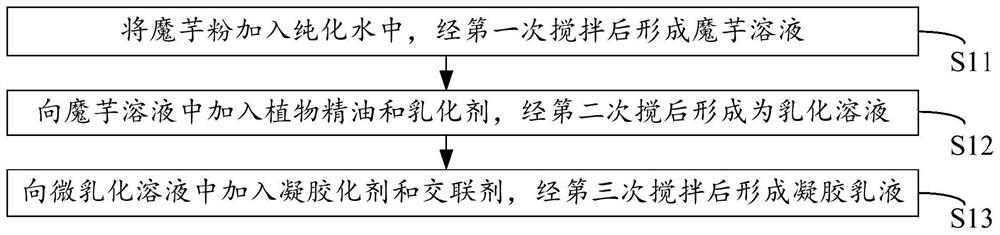

[0028] Step S10, konjac flour, plant essential oil, emulsifier, gelling agent, crosslinking agent and water are mixed and stirred to form a gel emulsion;

[0029] The quality of said konjac powder, plant essential oil, emulsifier, gelling agent and crosslinking agent is 2~8%, 2~4%, 1.1~1.5%, 0.8~1.2% and 0.05~0.07% of purified water quality. %. The baby wipes are made of konjac flour and plant essential oils, which are natural and non-irritating, and can effectively improve skin discomfort symptoms of infants such as diaper rash, saliva rash, and sweat rash. Pollution.

[0030] In this embodiment, the base material of the baby wipes is made of konjac fiber structure formed by processing konjac flour, wherein the content of glucomannan in the konj...

Embodiment 1

[0048] (1) Put 200g of konjac powder and 10kg of purified water in a stirring pot, and stir at 50rpm / min until the konjac powder is completely dissolved; Tween 20 and 50g lecithin, stirred at 2500rpm / min to form a microemulsion solution; then added 30g sodium carbonate, 50g sodium bicarbonate and 5g sodium trimetaphosphate in turn, stirred at 300rpm / min to form a gel lotion.

[0049] (2) Inject the gel emulsion prepared in step (1) into a 170mm*170mm wet tissue mold through a filling machine, wherein the filling volume is 20-40g; then keep the mold at 50°C for 12 hours, Take out the parison formed in the mold; quickly freeze the parison in the second year of cold storage at -30°C for 24 hours, take out the frozen parison and thaw it at natural temperature, rinse it with purified water for 2 to 3 times, and then perform centrifugal dehydration. Then, it is sterilized by moist heat to obtain the finished baby wipes; finally, after aseptic sealing packaging, it is the baby wipes...

Embodiment 2

[0051] (1) Put 500g of konjac flour and 10kg of purified water in a stirring pot, stir until the konjac flour is completely dissolved at 150rpm / min; 60 and 60g of monoglyceride laurate, stirred at 3500rpm / min to form a microemulsion solution; then add 40g of sodium carbonate, 60g of potassium carbonate and 6g of sodium trimetaphosphate in turn, and stirred at 600rpm / min to form a gel lotion.

[0052] (2) Inject the gel emulsion prepared in step (1) into a 170mm*170mm wet tissue mold through a filling machine, wherein the filling volume is 20-40g; then keep the mold at 65°C for 18 hours, Take out the parison formed in the mold; quickly freeze the parison in the second year of cold storage at -35°C for 36 hours, take out the frozen parison and thaw it at natural temperature, rinse it with purified water for 2 to 3 times, and then perform centrifugal dehydration. Then, it is sterilized by moist heat to obtain the finished baby wipes; finally, after aseptic sealing packaging, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com