Afterburning small turbofan engine for supersonic missile

A turbofan, afterburner technology, applied in the direction of machine/engine, jet propulsion, etc., to achieve high engineering application prospects, reduce fuel consumption, and improve the efficiency of afterburner work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

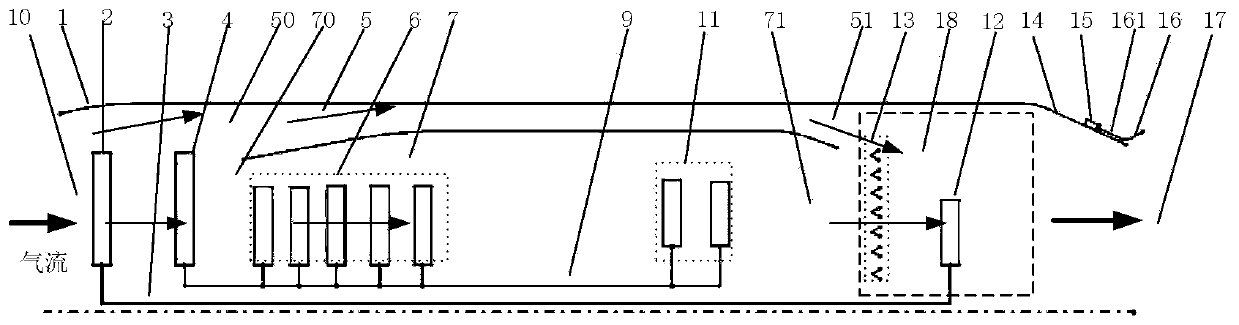

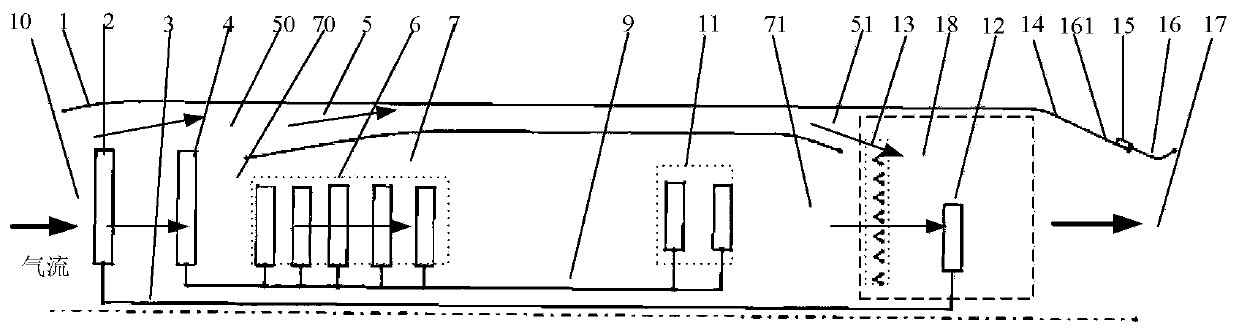

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Refer to figure 1 with 2 , An afterburner small turbofan engine for supersonic missiles, characterized in that it includes an engine body 1, an engine inlet 10, an engine outlet 17, an afterburner 18, an afterburner fuel injector 13, and

[0018] One-stage low-pressure fan 2, low-pressure shaft 3, afterburner turbine 12, one-stage low-pressure fan 2 and afterburner turbine 12 are installed at both ends of the low-pressure shaft 3;

[0019] The two-stage high-pressure fan 4, the high-pressure shaft 9, the high-pressure compressor 6, the high-pressure turbine 11, the two-stage high-pressure fan 4 and the high-pressure compressor 6 are installed at the first end of the high-pressure shaft 9, and the high-pressure turbine 11 is installed at the second end of the high-pressure shaft 9 ;

[0020] The high-pressure shaft 9 is sleeved on the low-pressure shaft 3;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com