Fuse pressing device

A fuse and fuse socket technology, which is applied in the manufacture of fuses, etc., can solve the problems of falling off, not being able to force down the fuse 100%, and pressing the fuse equipment to meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

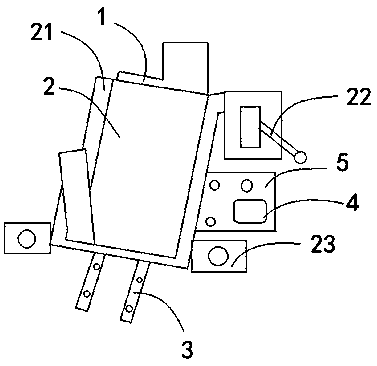

[0020] figure 1 It is a voltage fuse device according to an embodiment of the present invention, and the voltage fuse device includes:

[0021] The fuse box 1 includes a fuse element located between the line-side guide part and the load-side guide part;

[0022] The mold cavity 2 includes a casing 21, a mechanical fixing rod 22 and a double-control switch button 23. The casing 21 includes a fuse socket for receiving the above-mentioned fuse. The mechanical fixing rod 22 is located in the above-mentioned casing 21. The double-control switch button 23 is linked with the mechanical fixing rod 22 and is located on both sides of the above-mentioned housing 21. The double-control switch button 23 is used to control the mechanical fixing rod 22 to insert the above-mentioned fuse element into the above-mentioned socket and lock it; the housing 21 forms a Safe guards, housings made of insulating materials such as plastics and thermoplastics capable of withstanding the working environm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com