Stockpiling method

A stacking and material point technology, applied in the field of loading and unloading, can solve the problems of increasing equipment wear, wasting manpower, not designing the maximum stacking capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

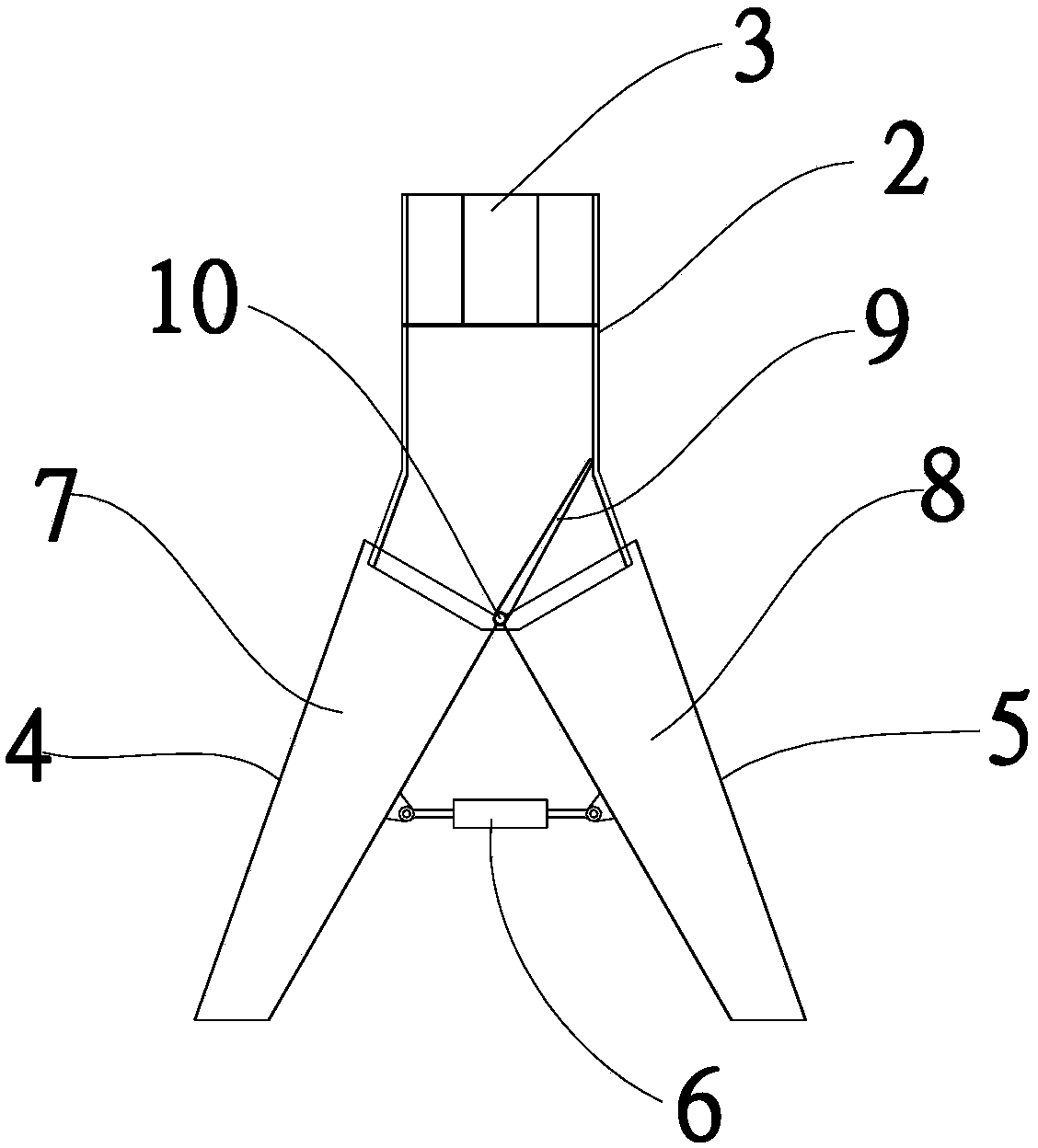

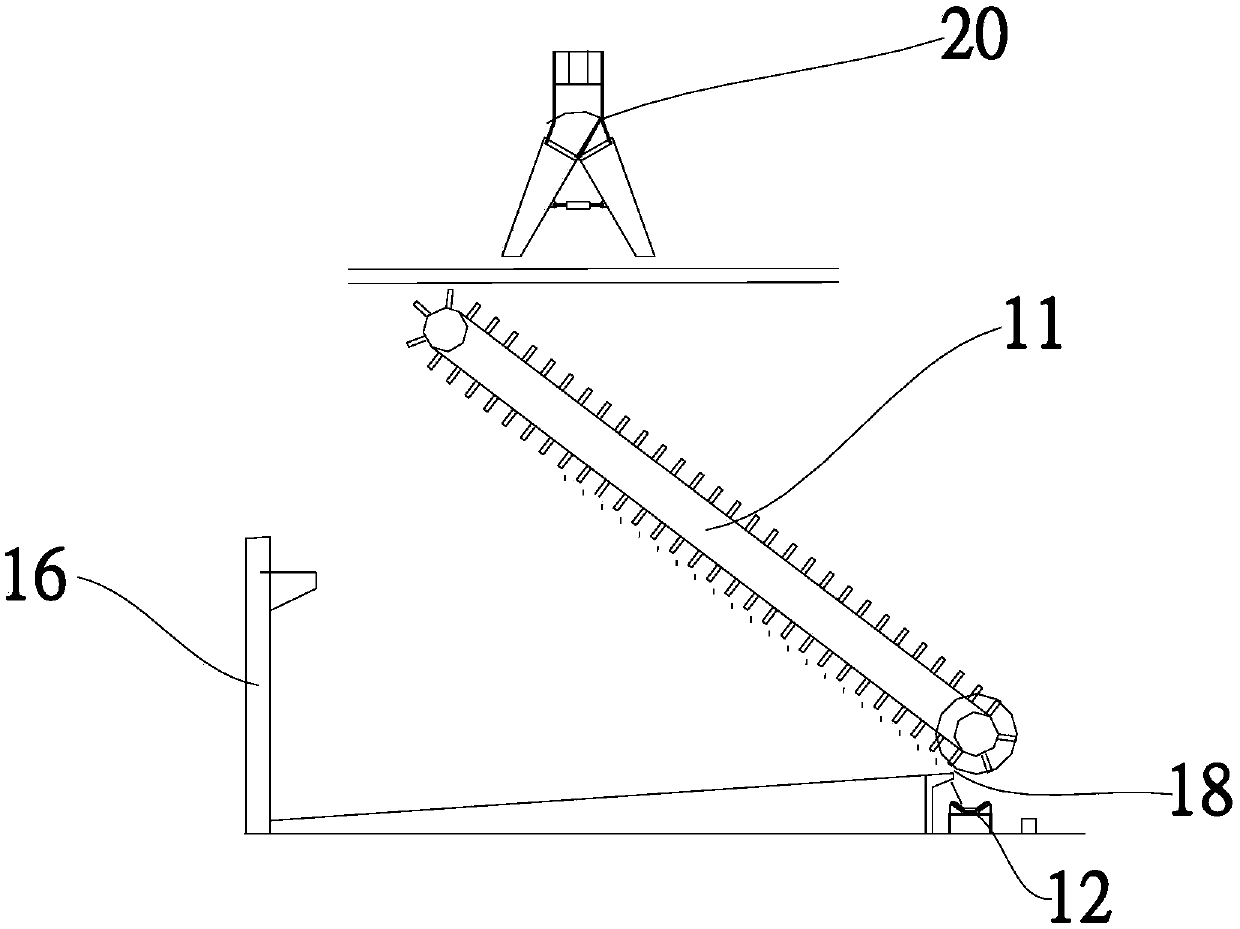

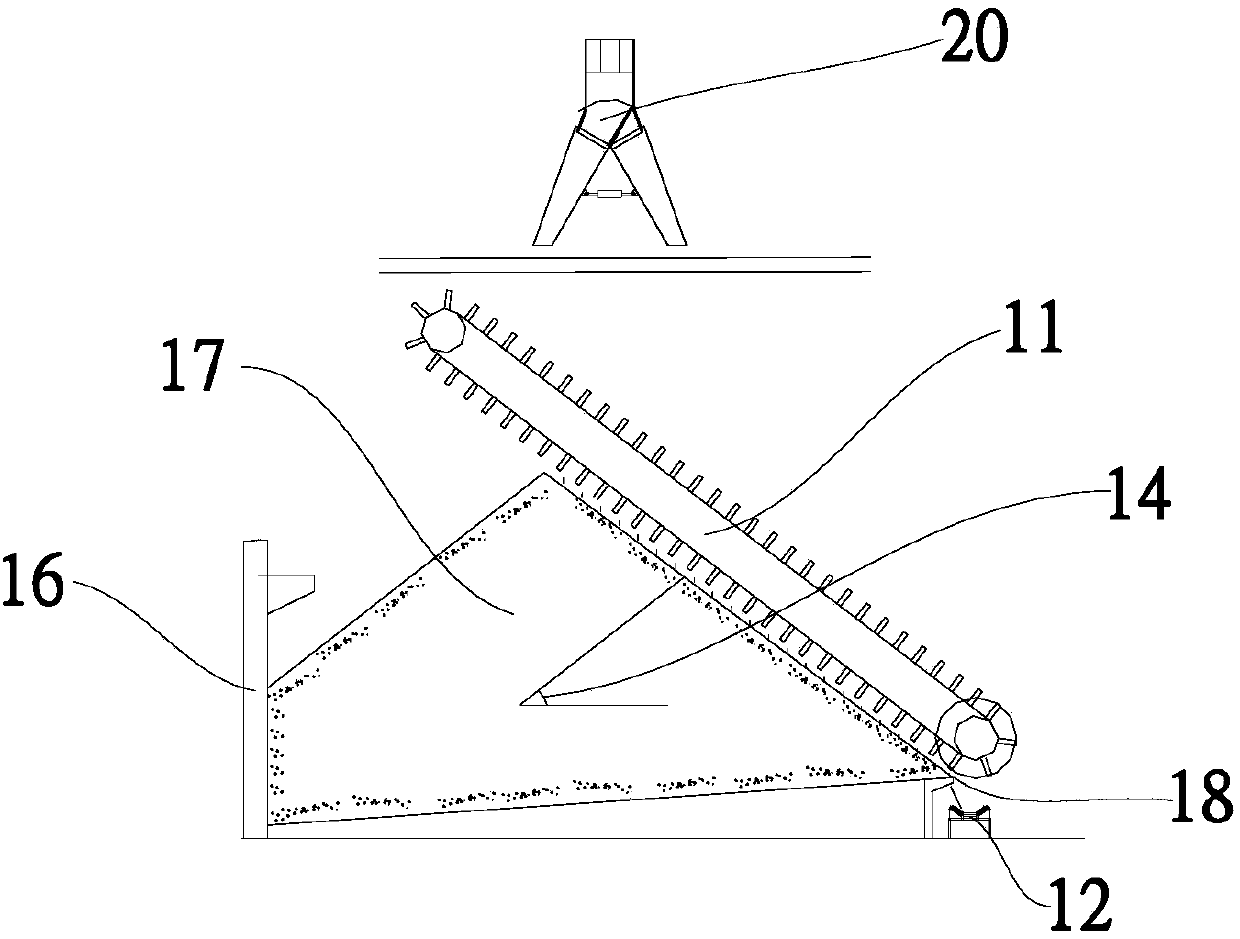

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

[0043] Embodiments of the present invention are as follows, as figure 2 , image 3 , Figure 4 and Figure 8 , a stacking method, comprising the steps of:

[0044] (1) Determination of the optimal unloading point: Calculate and determine the first position of the material pile along the width direction under the maximum material reserve in the storage yard according to the maximum reserve amount of the material, the length of the stockpile and the repose angle of the stockpile designed by the stockyard. Geometric cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com