Method for testing adhesive property of coating material under pressure water-seepage condition

A technology for coating materials and test methods, which is applied in rock or stone tests and concrete fields, and can solve problems such as inability to accurately reflect bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment provides a kind of test method for testing the bonding performance of the concrete coating material 9 under the pressure water seepage condition, comprising the following steps:

[0049] S1: Preparing concrete specimen 8 according to the mix ratio and standard curing for 28d;

[0050] S2: Apply sealant to the side of the concrete test piece 8, and fix it in the corresponding mold groove of the test bench, so that the concrete specimen 8 is flush with the bottom of the mold groove;

[0051] S3: After the sealant is completely cured, install the pressure tank 2 and inject water to pressurize it, and stabilize it for 0.5-2 hours after reaching the set water seepage pressure;

[0052] S4: coating the coating material 9 on the surface of the concrete specimen 8;

[0053] S5: After the coating material 9 is cured, apply an adhesive on the surface of the coating material 9 and place a steel jig for stretching, and install a tension detection device;

[0...

Embodiment 2

[0064] This embodiment provides a method for testing the critical value of the concrete coating material 9 against pressure and water seepage, comprising the following steps:

[0065] B1: Preparing concrete specimen 8 according to the mix ratio and standard curing for 28d;

[0066] B2: Apply sealant to the side of the concrete specimen 8, and fix it in the corresponding mold groove of the test bench, so that the concrete specimen 8 is flush with the bottom of the mold groove;

[0067] B3: After the sealant is completely cured, install the pressure tank 2 and inject water to pressurize it. The seepage pressure starts from 0.1MPa, and stabilizes for 0.5-2h after reaching the set seepage pressure, and then gradually increases the seepage pressure by 0.1MPa.

[0068] B4: Coating the coating material 9 on the surface of the concrete specimen 8, observing whether the coating material 9 can adhere to the surface of the concrete specimen 8, when the coating material 9 cannot be adhere...

Embodiment 3

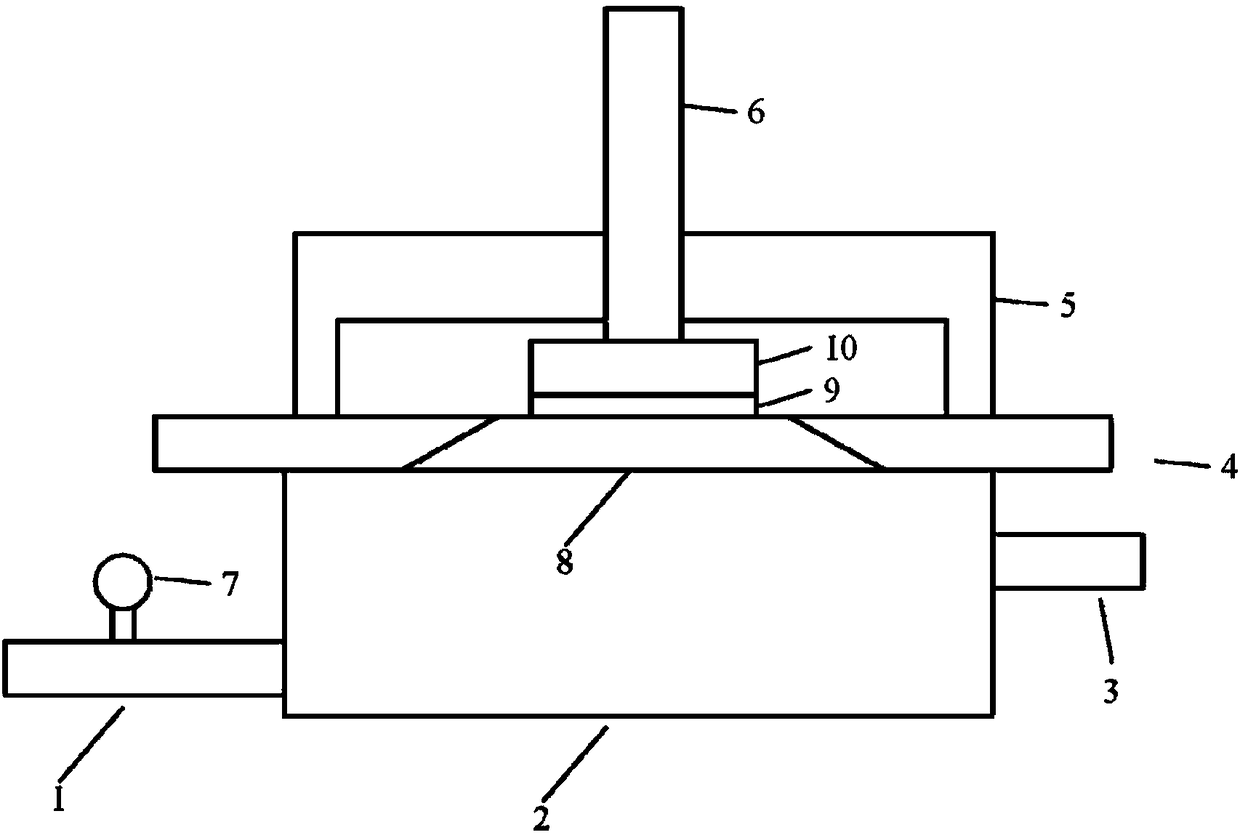

[0071] This embodiment provides a test equipment for testing the bonding performance of the coating material 9 under the condition of pressure and water seepage, including an experiment platform 4, a hydraulic loading device and a lifting instrument 6;

[0072] The experimental platform 4 has a test mold groove for accommodating the substrate test piece 8;

[0073] The hydraulic loading device is arranged at the bottom of the base material test piece 8, and is used to pressurize the base material test piece 8;

[0074] The lifting instrument 6 is arranged on the upper part of the experimental platform 4, and is used to pull the coating material 9 coated on the upper surface of the substrate test piece 8, so as to measure the distance between the coating material 9 and the upper surface of the substrate test piece 8. cohesion.

[0075] In the optional solution of this embodiment, more preferably,

[0076] The hydraulic loading device includes a pressure tank 2 and a pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com