Double wing pineapple picking truck

A pineapple and double-wing technology, applied in harvesters, agriculture, applications, etc., can solve the problems of not being able to pick pineapples quickly on a large scale and a large amount of manpower and material resources, and achieve the effect of saving manpower and material resources, and efficient and reliable picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

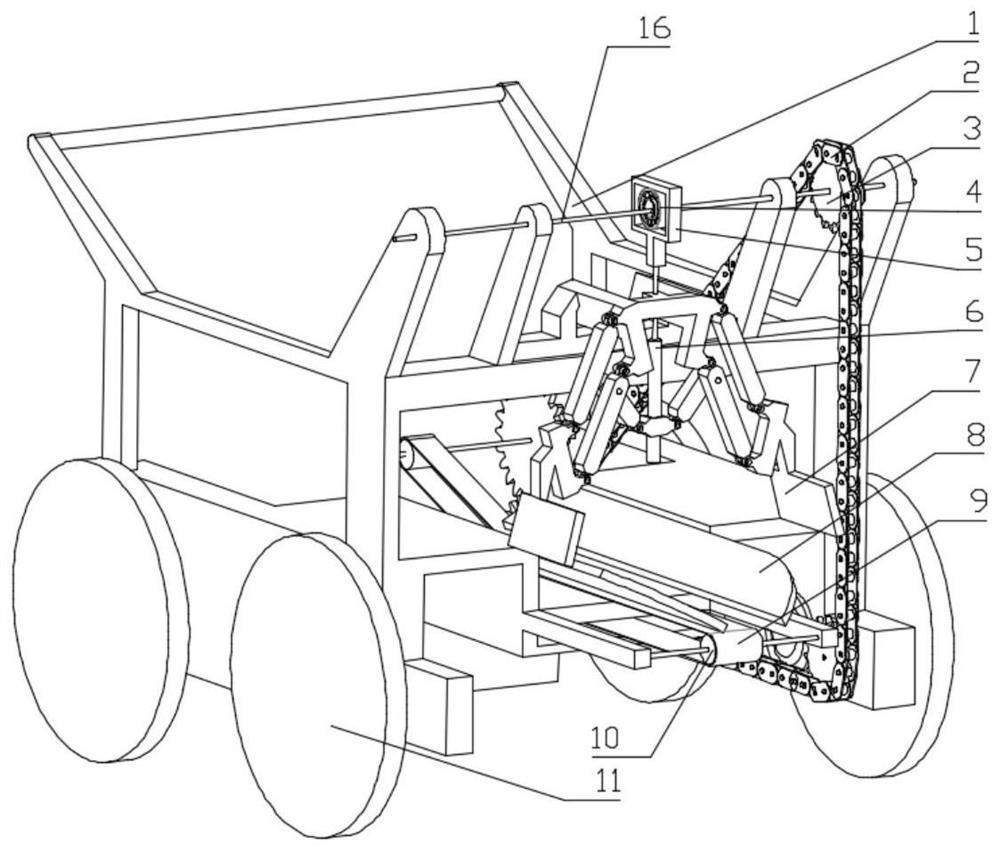

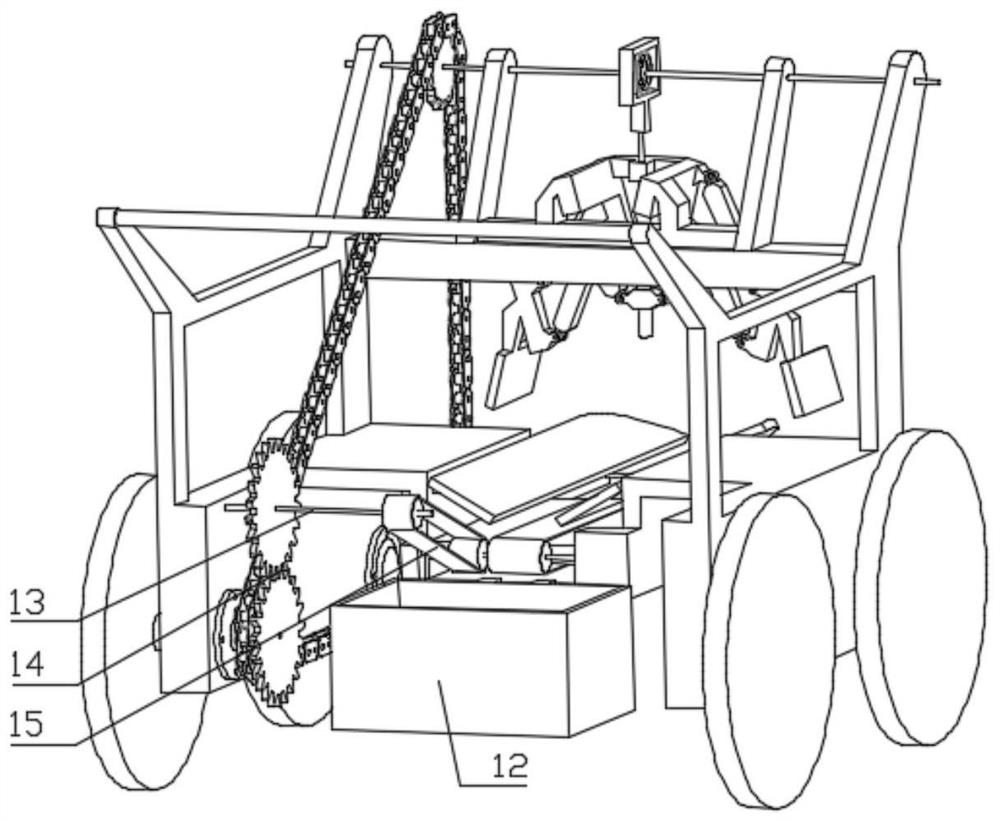

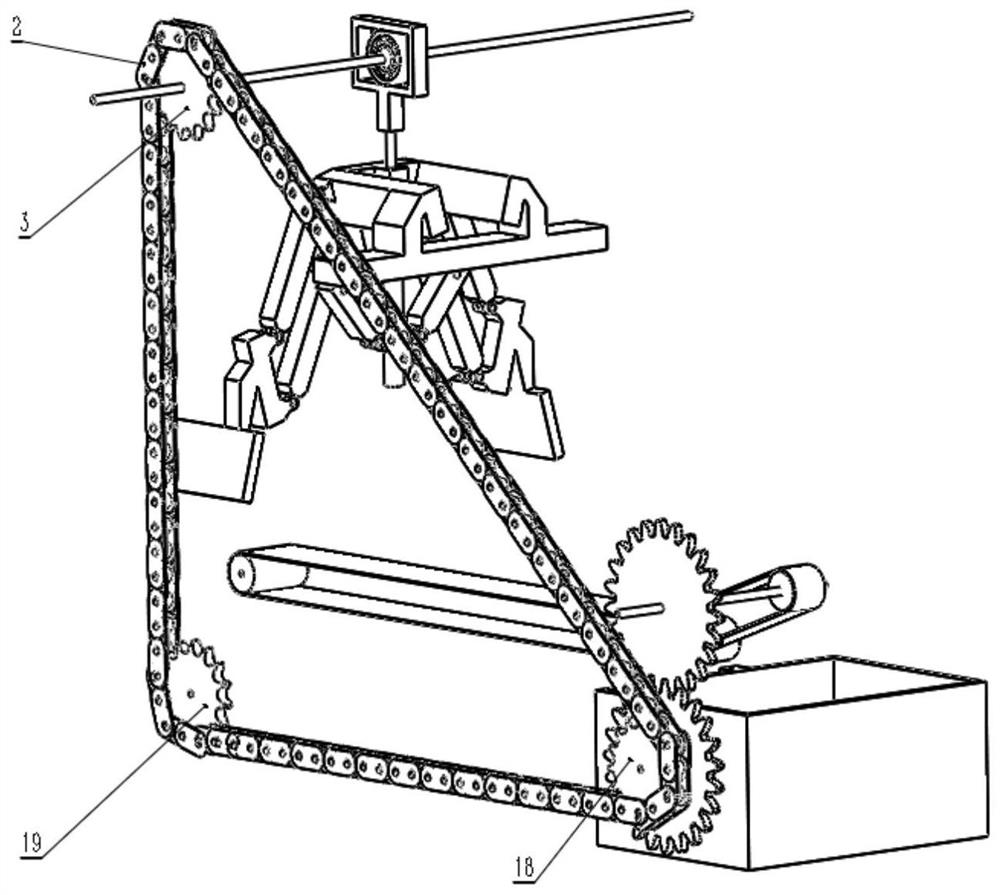

[0025] Embodiment 1 The specific structure of the two-wing pineapple picking vehicle of the present invention

[0026] The double-wing pineapple picking vehicle of the present invention can realize auxiliary manual picking of pineapples, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes picking parts, collecting parts, power transmission parts, and supporting parts, wherein the picking parts include a set of flat-bottomed straight-moving driven rod cam mechanisms, a pair of symmetrically installed slider rocker mechanisms 6, two sets of flat four The rod mechanism (which can be designed as a parallelogram structure) and a pair of symmetrically installed inner support guide plates 8 and clapping plates 7 are composed; the collection components include a transmission belt 9, two transmission pulleys 10, and a collection box 12; the power transmission components include Chain 2, first sprocket 3 and second sprocket 18, tensioning s...

Embodiment 2

[0030] Embodiment 2 The method of using the double-wing pineapple picking vehicle of the present invention

[0031]Run the car to the pineapple plantation, allow the wheels to straddle outside the two rows of pineapples, make the inner support guide plate 8 between the two rows of pineapples, let the picking car advance, and at this moment, the clapping plate 7 begins to set like a bird's wing The slapping movement is performed within the range of the pineapple stem, because the pineapple stem is supported by the outer edge of the inner support guide plate 8, and the slapping plate 7 gives the pineapple a force to measure the inside of the car, so that the pineapple and the stem are broken and separated. The pineapples will roll onto the conveyor belt 9 along the slope of the inner support guide plate 8, and then be sent to the collection box 12 located at the rear lower part of the car. As the car moves forward, the pineapples are constantly taken off and collected. When the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com