Water vapor generating method of coke reactivity measuring device

A technology of steam generation and steam generator, which is applied in steam generation method, measurement device, steam generation and other directions, can solve the problems of inaccurate determination of coke reactivity, increase the specific surface area of the body, reduce the energy consumption of iron making, Anti-splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

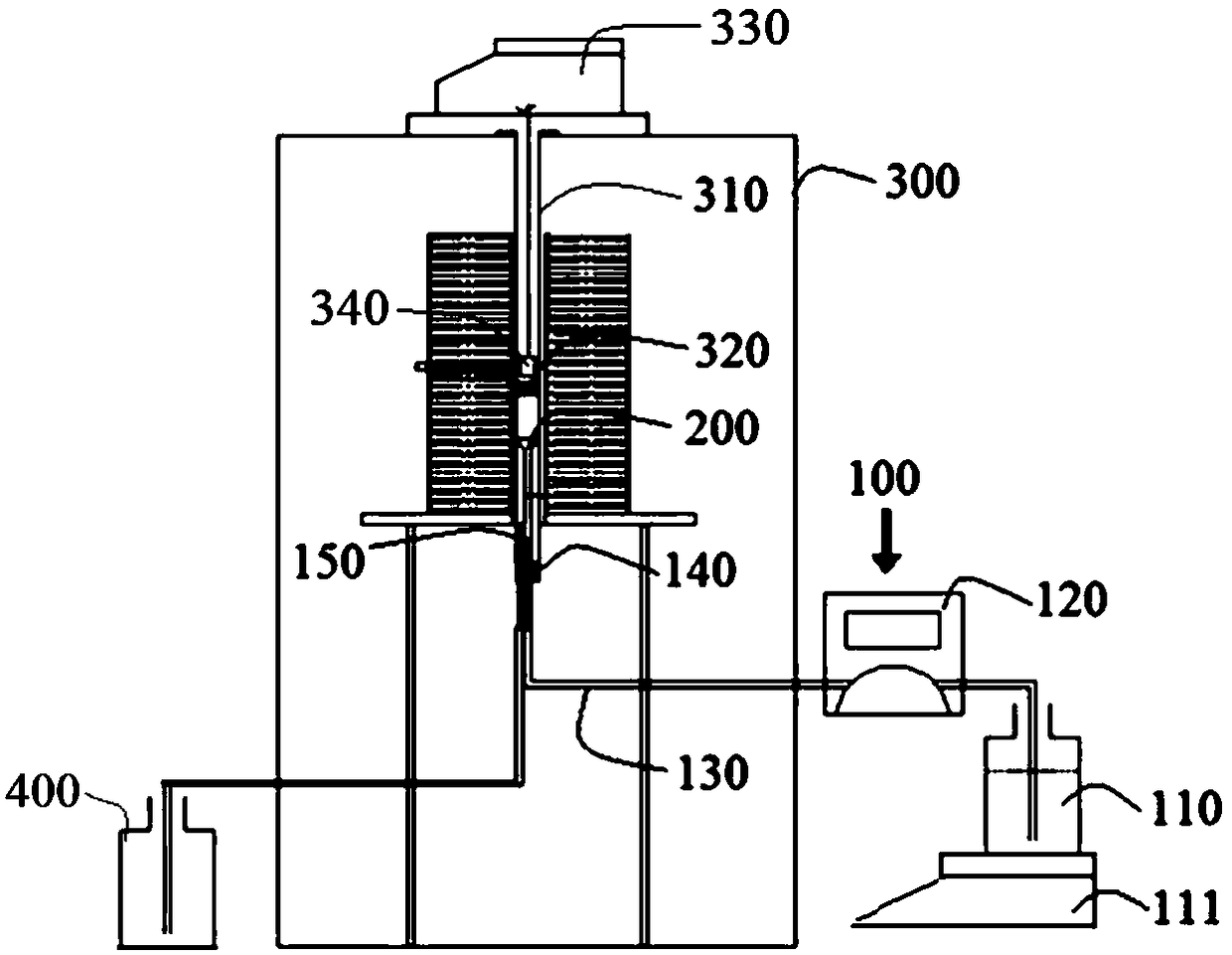

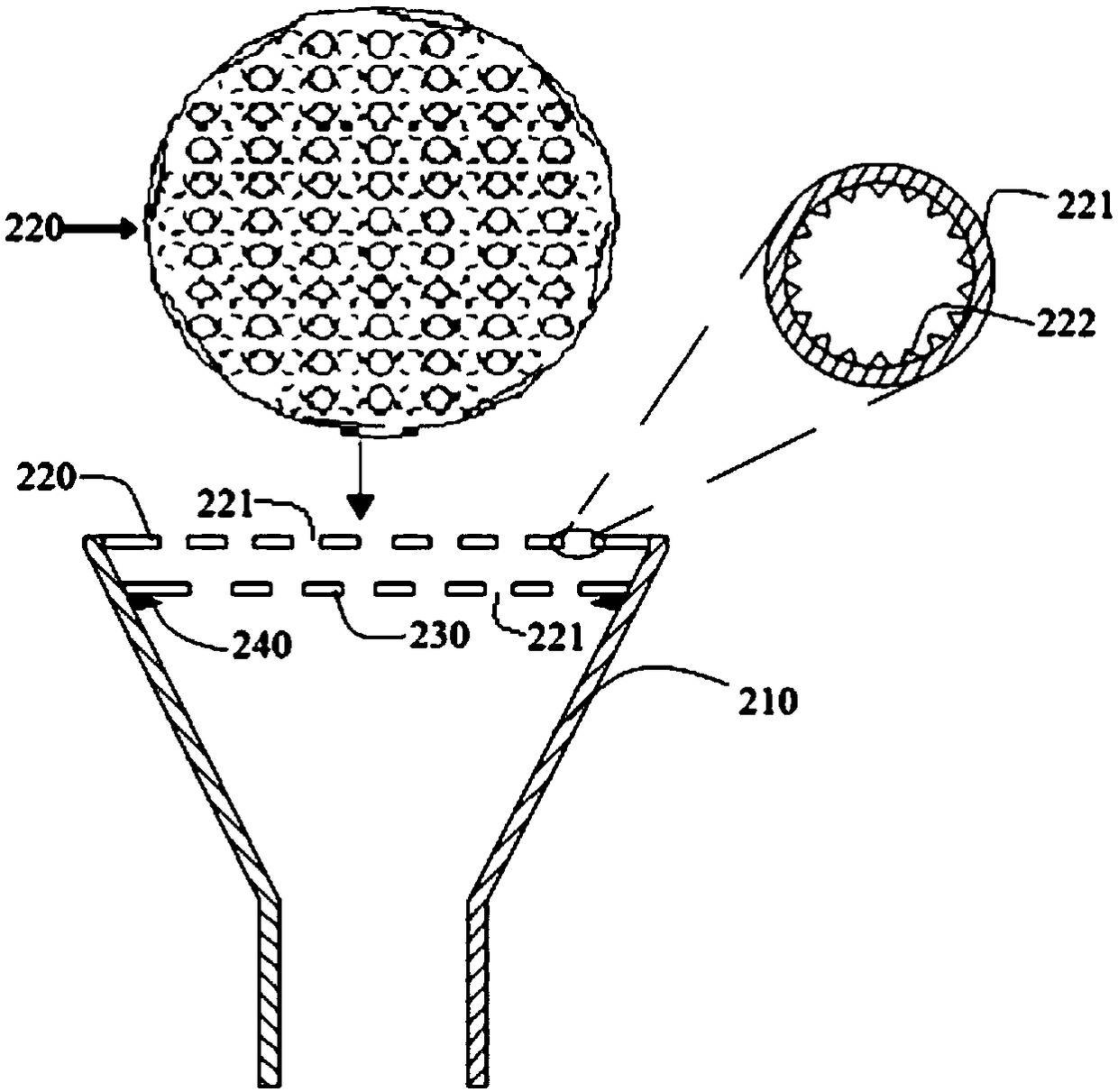

[0041] Refer to attached figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the water vapor generation method of a coke reactivity measuring device in this embodiment, the water vapor generation device adopted includes an infusion unit 100, an evaporation unit 200 and a heating furnace 300, and the infusion unit 100 and the evaporation unit 200 pass through the liquid supply pipe 130 connection, the evaporation unit 200 is set in the quartz tube 310 inside the heating furnace 300 . The infusion unit 100 is used to deliver the distilled water required for the experiment, the evaporation unit 200 is used to evaporate the distilled water, and the heating furnace 300 is used to provide the temperature required for evaporation. The heating furnace 300 is provided with a quartz tube, and the top of the heating furnace 300 is provided with a scale A weighing balance 330 , a sample cage 340 is suspended from the lower part of the weighing balance 330 , and the steam generator...

Embodiment 2

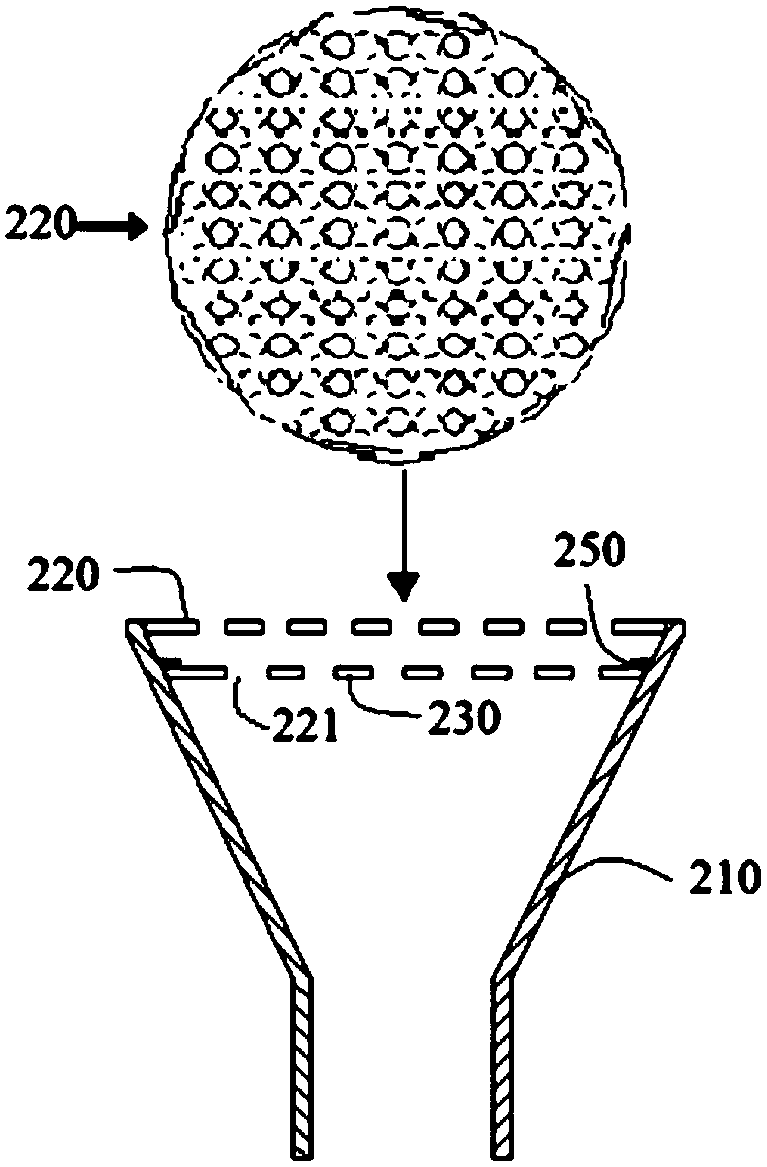

[0057] Refer to attached figure 1 , image 3 , Figure 4 and Figure 5 As shown, the water vapor generation method of a coke reactivity measuring device in this embodiment, the experimental device adopted is basically the same as that of embodiment 1, the difference of the device is that the lower stabilizing plate 230 is not fixedly arranged on the water vapor Steam generator 210, that is, the lower stabilizing plate 230 can float up and down in the steam generator 210 with the height of the liquid level; the lower end of the lower stabilizing plate 230 is not provided with a liquid level detection mechanism 240, but the lower steady The upper end of the flow plate 230 is provided with a contact probe 250, and the contact probe 250 is arranged on the side wall of the steam generator 210. When the lower flow plate 230 floats up with the rise of the liquid level, it will touch the contact probe. 250. At this time, reduce the power of the speed-regulating peristaltic pump 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com