Intelligent blade mould

An intelligent blade and mold technology, applied in the field of wind power blade mold manufacturing, can solve the problems of large human influence, various models, and low degree of mold automation, and achieve the effect of improving comprehensive management level, avoiding product defects, and enriching data support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

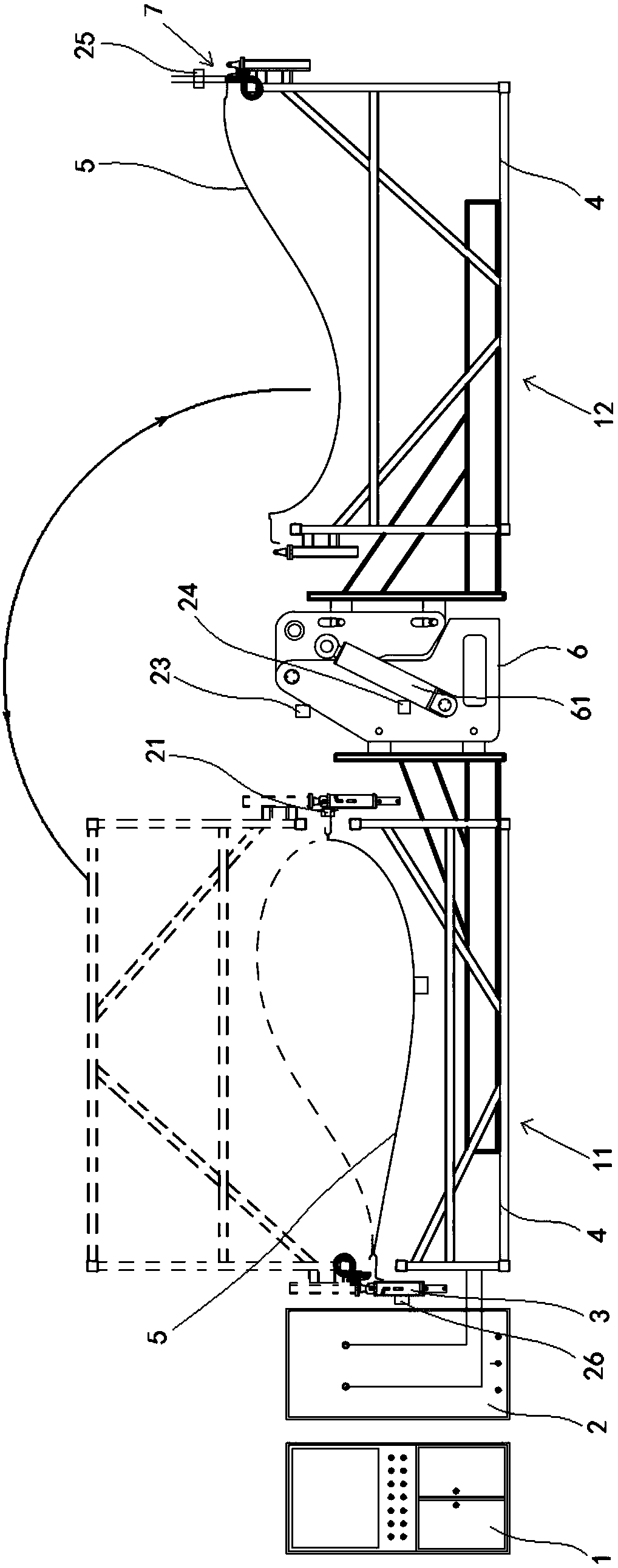

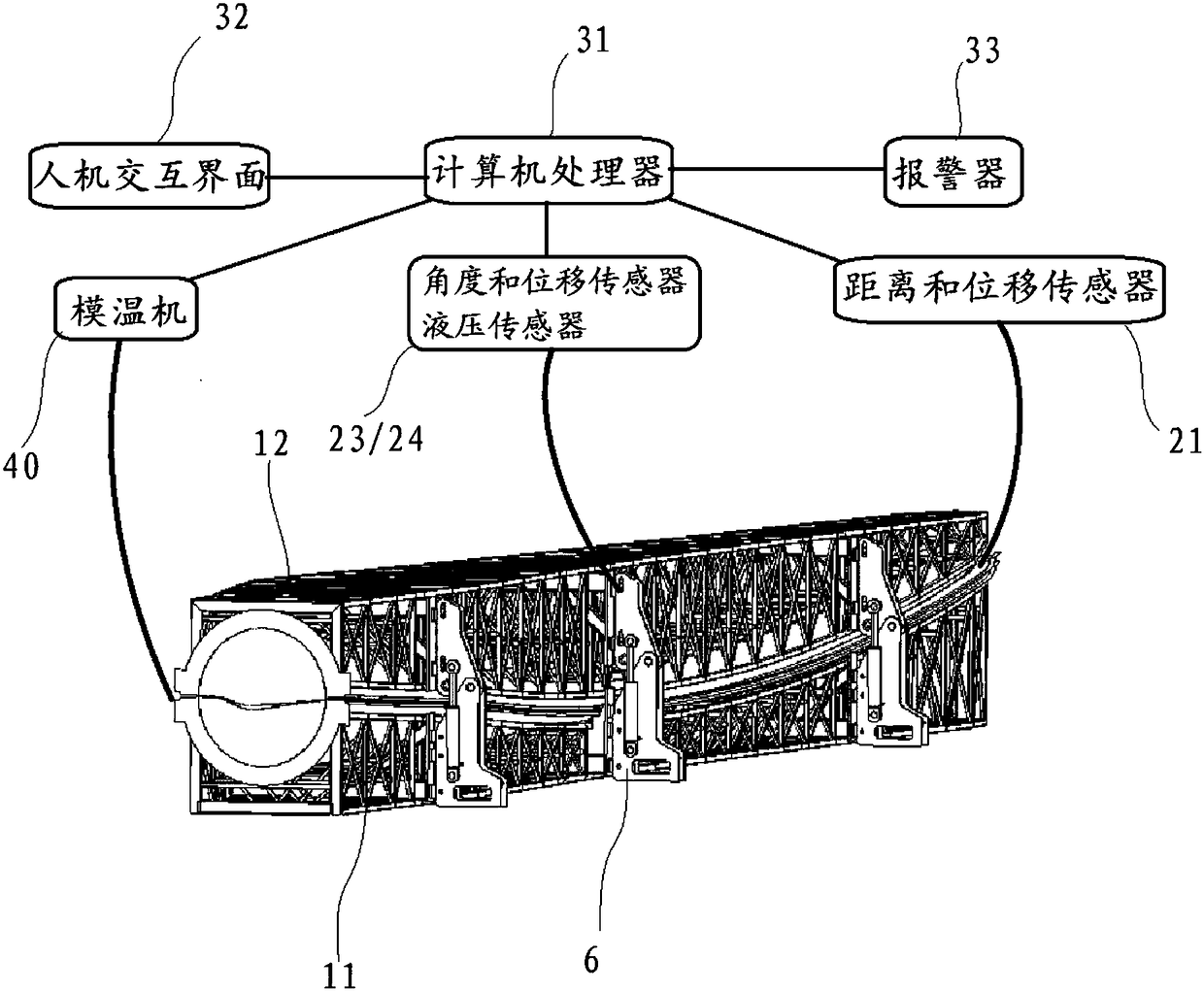

[0027] Exemplary embodiments of the present invention are described with reference to the drawings.

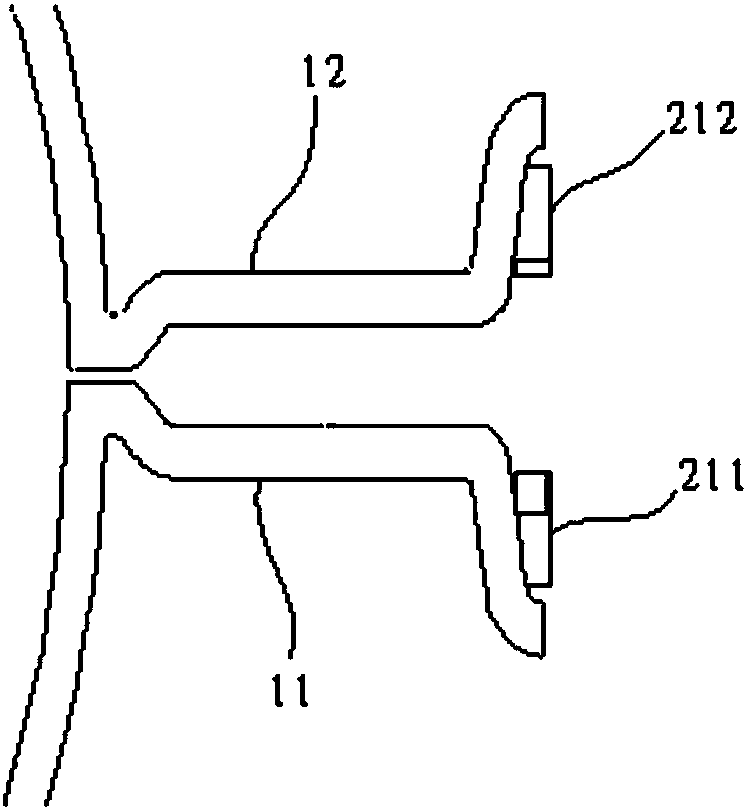

[0028] refer to Figure 1 to Figure 2 , the intelligent blade mold of the present invention comprises: a fixed surface mold 11 and an overturned surface mold 12; an overturning system 6 for selectively closing the fixed surface mold 11 and the overturned surface mold 12; for locking the fixed surface mold 11 Locking and jacking system 3 for tightening or lifting the mold 12 on the inverted surface; heating system 2 for heating the mold 11 on the fixed surface and / or the mold 12 on the inverted surface; and a vacuum system 7 connected to the mold 11 on the fixed surface; also includes , the distance and the displacement sensor 21 arranged between the fixed surface mold 11 and the inverted surface mold 12, the temperature sensor 22 arranged in the fixed surface mold 11 and / or the inverted surface mold 12, the angle and displacement arranged in the inverted system 6 The sensor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com