A bridge expansion joint structure

A technology for expansion joints and bridges, applied in bridges, bridge materials, bridge construction, etc., can solve problems affecting driving speed, comfort and safety, inability to inspect and maintain expansion joints, and insufficient firmness of the structure, etc., to achieve good bearing capacity, Satisfy the effects of stretching and deformation, stronger structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

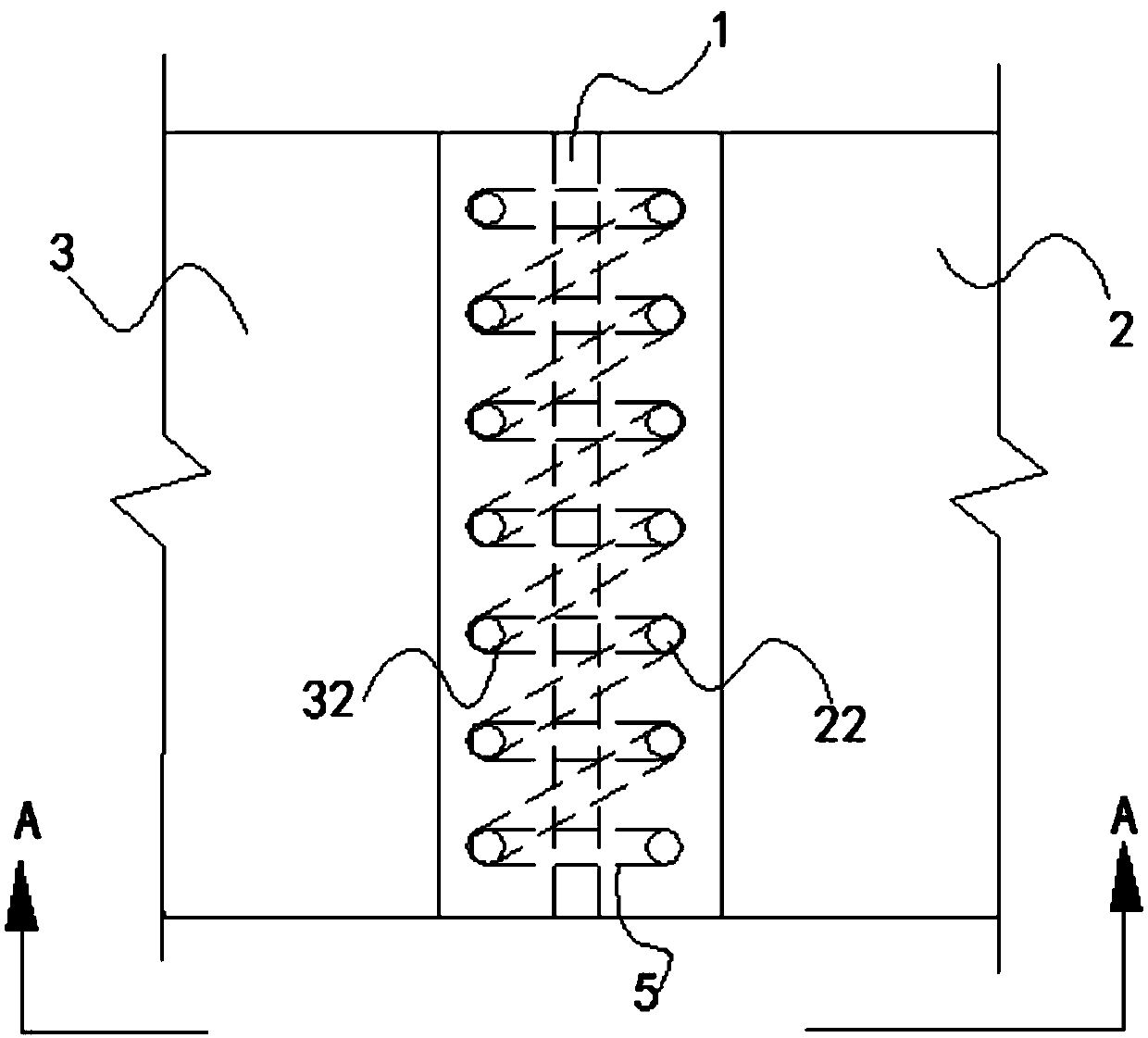

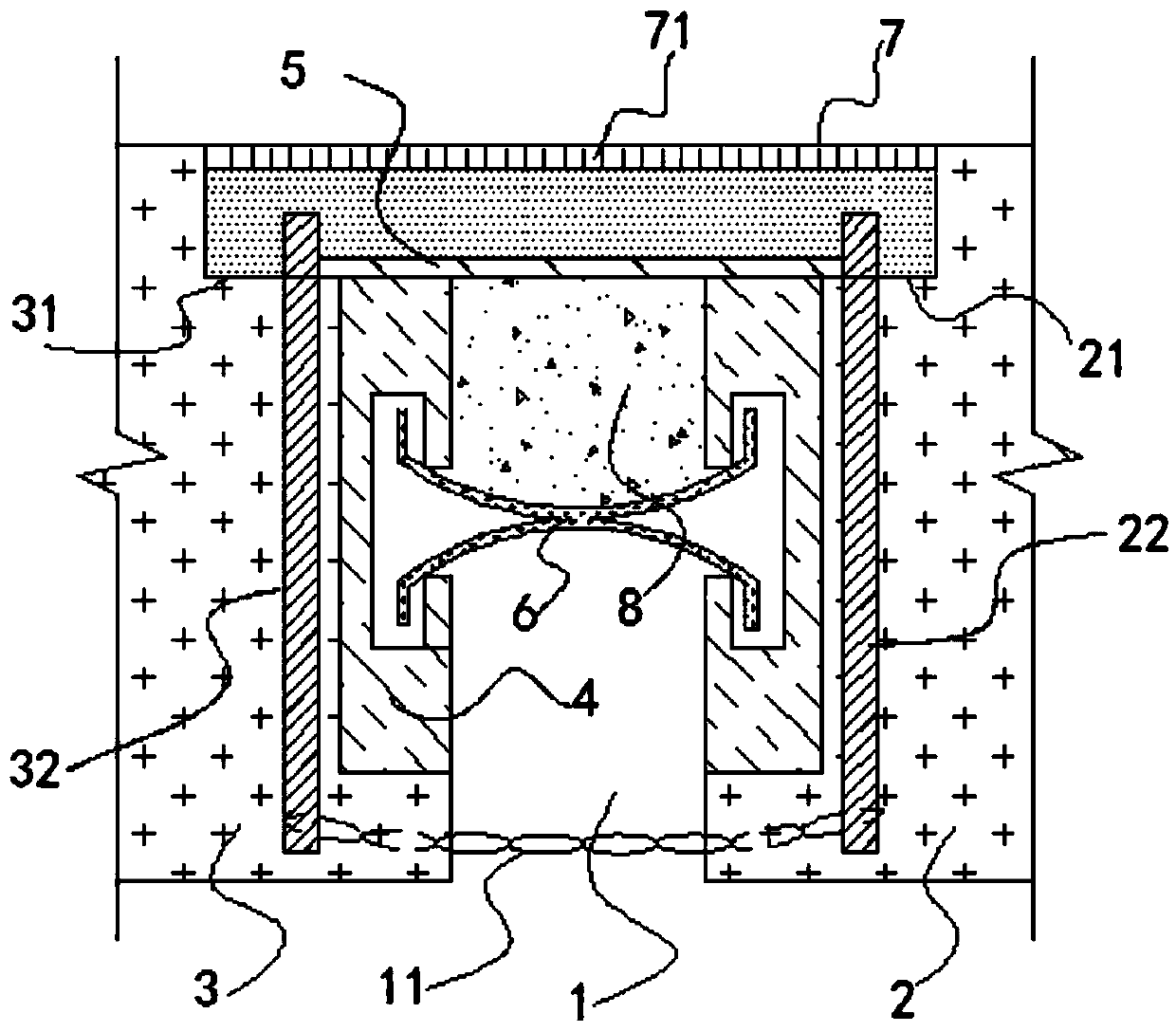

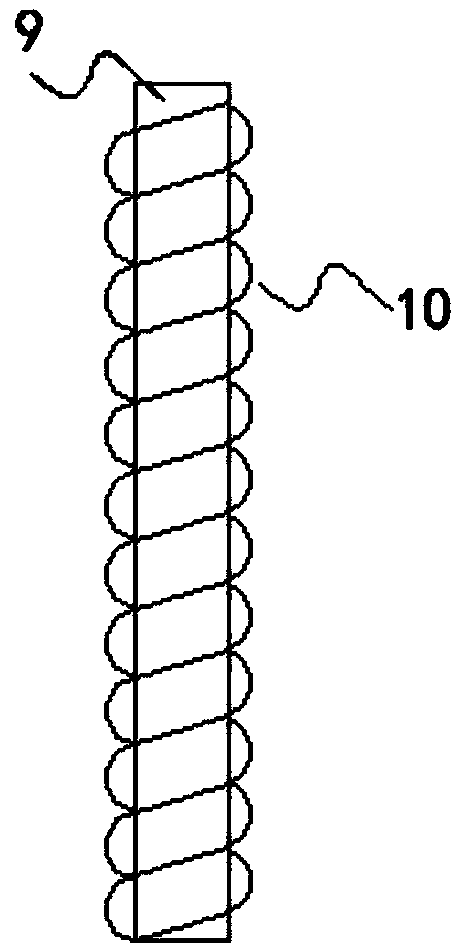

[0037] Embodiment: a kind of bridge expansion joint structure, as Figure 1-Figure 7, including a bridge body and an expansion joint 1, the expansion joint is located at one end of the bridge body, the expansion joint divides the bridge body into a first bridge body 2 and a second bridge body 3, the first bridge body is close to the expansion joint One end of the seam is concave to form a first supporting step 21, and the end of the first supporting step away from the expansion joint is equidistantly provided with a plurality of first fixing columns 22 distributed along the width direction of the bridge main body, and the first fixing columns Perpendicular to the bridge main body, one end of the second bridge main body close to the expansion joint is recessed to form a second supporting step 31, the second supporting step is flush with the first supporting step, and the first supporting step is The end of the two supporting steps away from the expansion joint is equidistantly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com