Abutment Connection Structure and Construction Method of Integral Composite Girder Seamless Bridge

An abutment and structure technology, which is applied to the abutment connection structure and construction field of integral composite girder seamless bridge, can solve the problems of increased impact of heavy vehicles, impact on service life, and reduced stiffness of joints, and achieve processing accuracy Easy to guarantee, low construction cost, and the effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

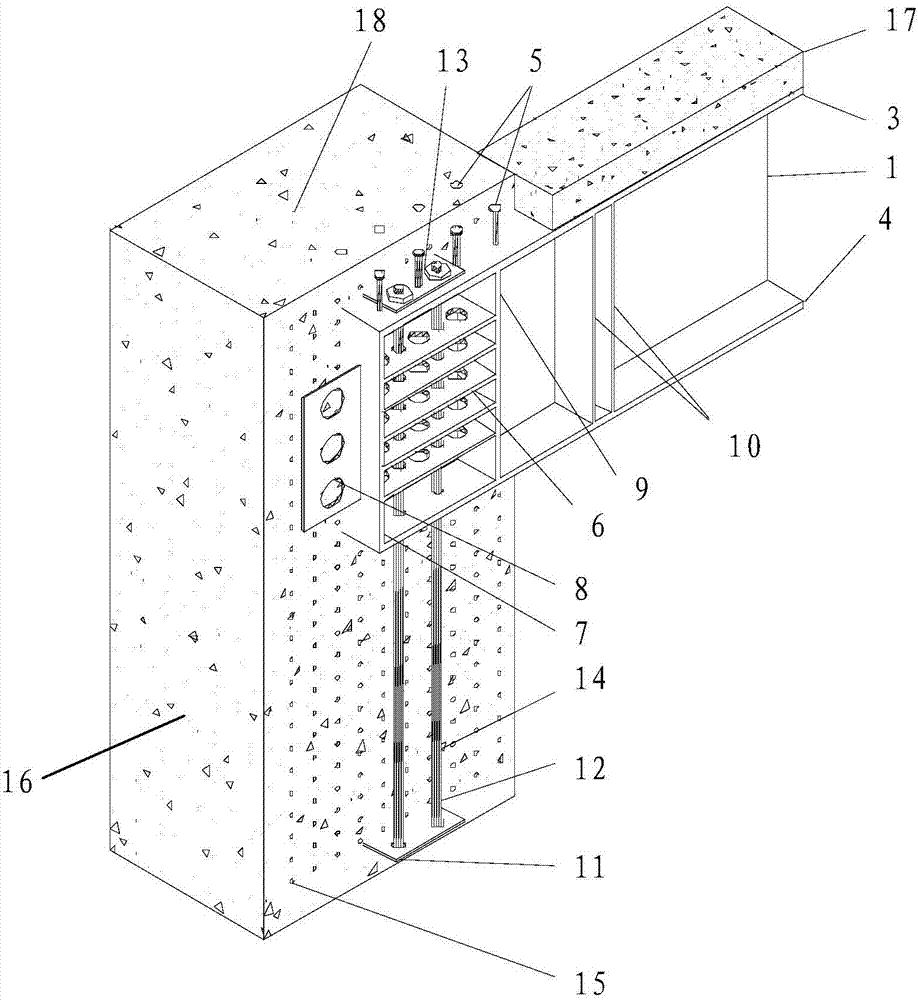

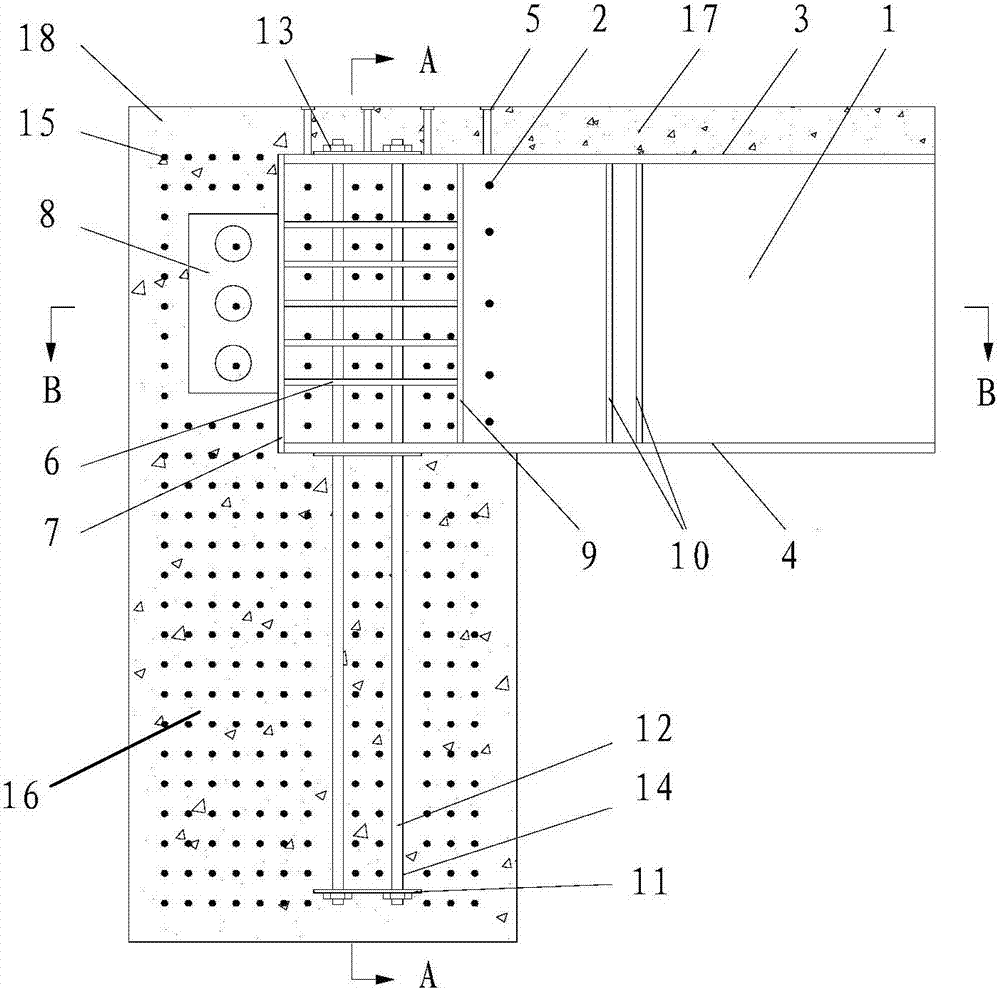

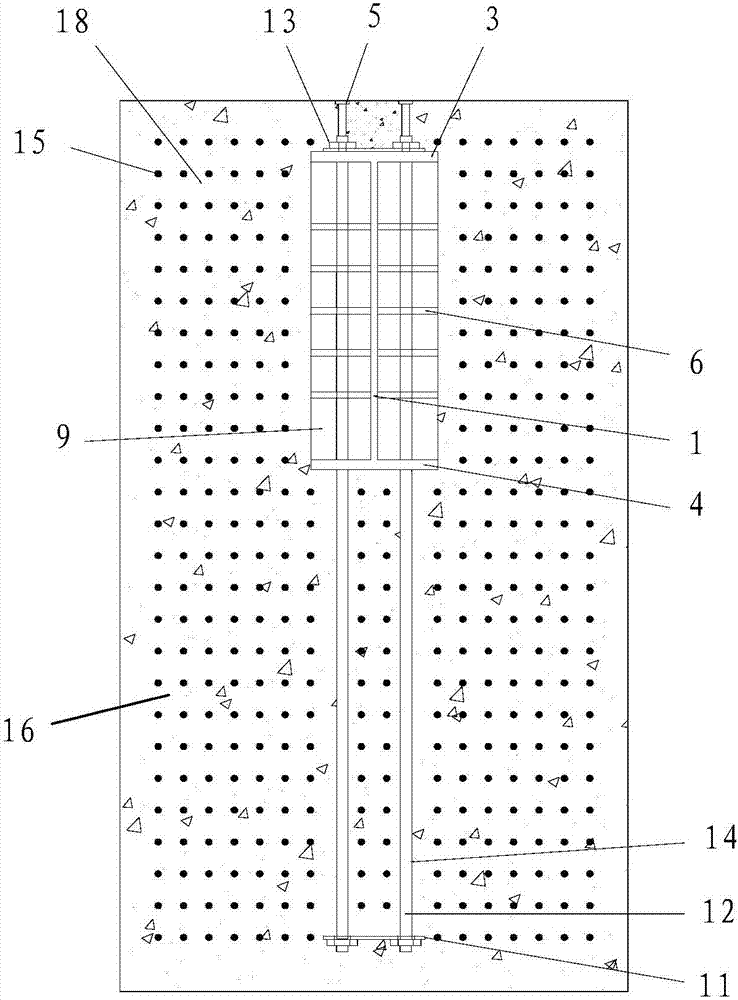

[0057] Such as figure 1 , figure 2 , image 3 and Figure 4 The abutment connection structure of an integral composite girder seamless bridge is shown, including a controllable prestressing system, a connection system and a stiffening system arranged on the composite girder of the constructed seamless bridge, and the composite girder includes steel The main girder and the concrete bridge deck 17 paved on the steel main girder; the outer section of the steel main girder extends into the abutment 18 of the seamless bridge being constructed, and the outer section of the steel main girder It is the connecting section of the beam body; the abutment 18 is located on the pile cap 16 of the pile foundation of the abutment, and the abutment 18 and the pile cap 16 are both reinforced concrete structures and the two are cast as one.

[0058] The connection system includes a plurality of vertical shear members fixed on the upper part of the beam body connection section and two sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com