A protective tooling for installing anti-fugitive fillers

A tooling and anti-escape technology, applied to valve devices, valve details, engine components, etc., can solve problems such as leakage, bonnet inner hole strain, failure, etc., to reduce opening and closing torque, ensure sealing performance, and good guidance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

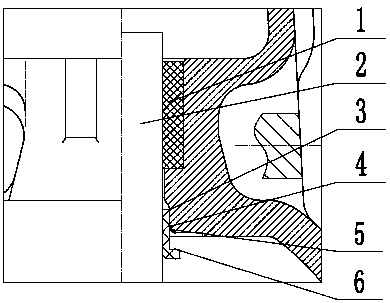

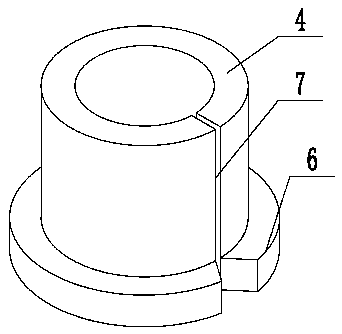

[0019] Such as figure 1 , 2 As shown, a protective tool for installing anti-emission packing includes a soft bushing 4, the soft bushing 4 is lined in the bonnet hole 5, and the inner diameter of the soft bushing 4 is smaller than the inner diameter of the bonnet hole 5, When installing the valve stem 2, ensure that the valve stem 2 is in zero contact with the valve cover hole 5 to avoid scratches on the valve stem 2; The take part 6 facilitates the axial detachment of the soft bush 4 from the bonnet hole 5, the valve stem 2 is put into the soft bush 4, and the soft bush 4 is provided with a dividing surface 7, and the soft bush 4 is removed from the After the valve cover hole 5 is axially disengaged, it is peeled off from the valve stem 2 through the dividing surface 7 .

[0020] In the optimized scheme, the valve cover hole is provided with an installation groove 3, and the soft bushing 4 is lined in the installation groove 3 of the valve cover hole 5, which facilitates th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com