Anti-loosening metal gasket with fool-proof structure and mounting method of anti-loosening metal gasket

A metal gasket and anti-loosening technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve problems such as low installation efficiency, failure of anti-loosening gaskets, misinstallation and misuse of gaskets, etc., to improve efficiency and ensure anti-loosening effect, the effect of avoiding relative motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

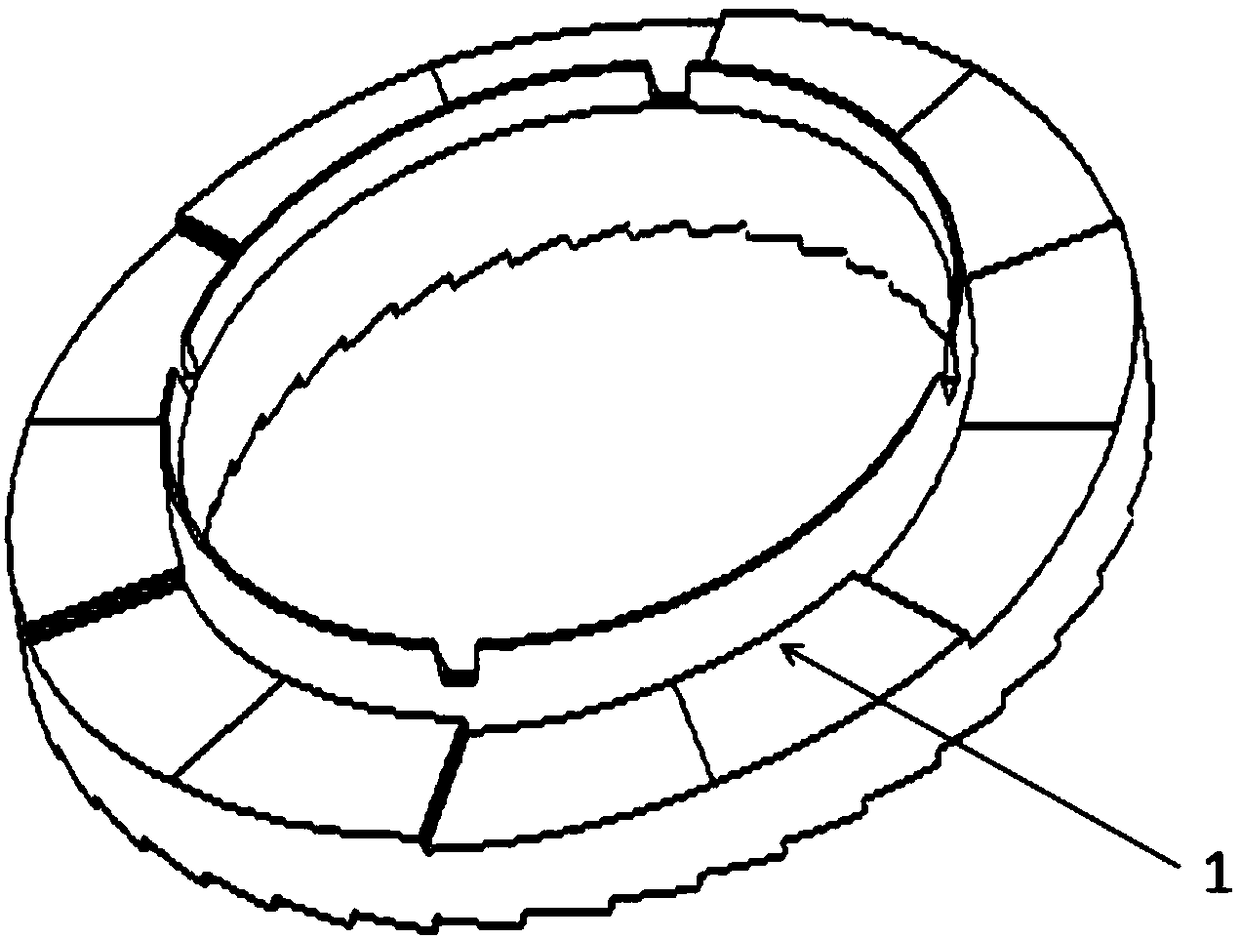

Examples

Embodiment

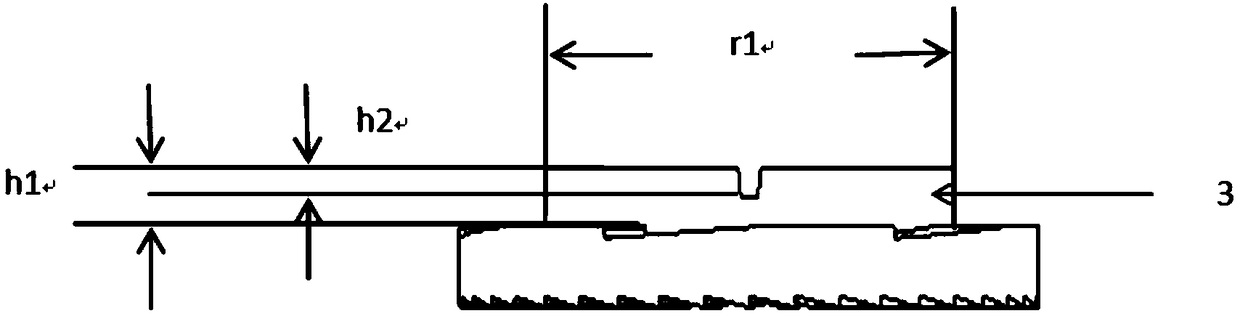

[0028] Taking the self-locking washer of M16 specification as an example, the height of the boss of the A washer is set to h1=1.65mm, the height of the riveted fold is h2=0.75mm, and the thickness of the sinking table of the B washer is d2=0.35mm, then when the A and B washers After being riveted together, the reserved height H in the vertical direction is:

[0029] H=h1-h2-d2=0.55mm………………(1)

[0030] There is still room for movement when the relative staggering of the gasket produces the maximum lifting height, that is, the maximum pre-tightening force.

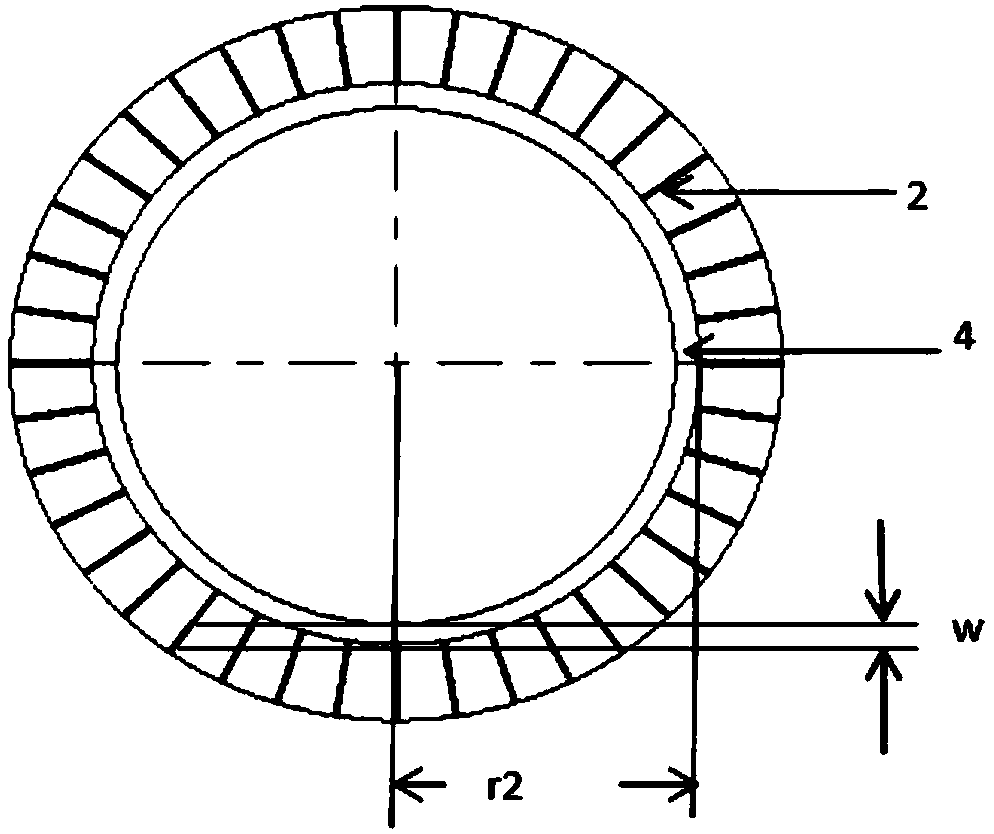

[0031] In addition, the radius difference between the inner rings of the A washer and the B washer is Δr=r2-r1=1.5mm, the thickness of the boss of the A washer is d1=0.33mm, and the width of the sinking platform of the B washer is w=0.8mm, then when the A and B washers are riveted together, There is a gap L reserved in the horizontal direction as:

[0032] L=Δr-d1-w=0.4mm..........(2)

[0033] Avoid hindering the relative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com